What Is an Air Compressor and How Do They Work?

Introduction to Air Compressors

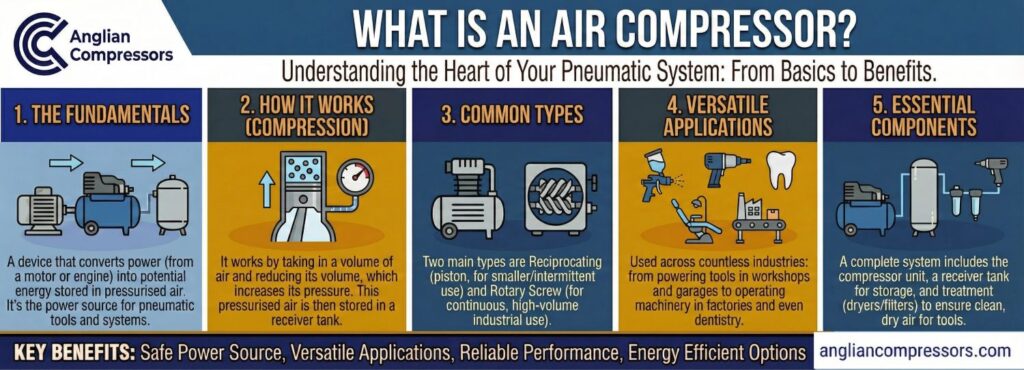

Air compressors work by converting energy using sources like electric motors or engines into versatile compressed air, vital for tools, machinery, and processes like material handling and medical equipment. They have significantly impacted industries for decades by providing reliable sources of compressed air.

Historically, the idea of compressing air dates back to ancient times, with John Smeaton’s 18th-century mechanical compressor being a pivotal step. Today, air compressors are used extensively across the manufacturing industry, pharmaceutical, construction, and automotive industries.

Often regarded as the “fourth utility” alongside electricity, water, and gas, compressed air’s clean, adaptable nature ensures its indispensability in modern industrial operations.

Modern advancements in air compressor technology, such as oil-free systems and variable speed drives (VSDs), have further enhanced their efficiency and versatility. These innovations have reduced energy consumption and improved sustainability in industrial applications.

Basic Principles of Air Compressors

Air compressors are vital for industries, offering dependable pressurised air. They draw in atmospheric air and compress it to increase pressure, creating potential energy stored in a tank. This energy can later be released, powering tools or machinery with kinetic energy.

Air compressors utilise elements like intake valves, pistons, and impellers. As pistons descend or impellers rotate, ambient air is drawn in due to decreased pressure. As they move or continue rotating, the trapped air gets compressed, increasing pressure. When this compressed air is released, similar to an inflated balloon, the pressure release transforms potential energy into kinetic energy, which can power pneumatic tools.

Innovative features such as integrated SmartLink monitoring systems in compressors enable real-time performance tracking, ensuring operational efficiency and reducing downtime.

Types of Air Compressors

There are different types of air compressors available, each offers distinct functions and advantages. Familiarising yourself with these differences can help you choose the ideal air compressor for your specific requirements.

Dynamic Compressors

Dynamic air compressor creates pressure by employing the principle of accelerating and decelerating air. Rapidly increasing the velocity of incoming air leads to an increase in its kinetic energy.

The fast air enters a diffuser, slowing and converting kinetic energy is transformed back into pressure energy through deceleration. This change from speed to pressure ensures the compressed air reaches the required pressure level.

Dynamic compressors attain the necessary pressure increase by propelling air or gas with an impeller and subsequently decelerating it in a diffuser. This compressor is prominently utilised for tasks demanding large volume flow rates of air.

There are two primary kinds of air compressor: centrifugal and axial compressors.

Centrifugal compressors

Known for their compactness, minimal maintenance, and smooth operation, they use impellers for tasks like HVAC and gas turbines, and are suited to operations requiring high volumes of air.

Axial compressors

Typically used in applications that require higher pressure ratios and lower flow rates, such as aircraft engines and power plants, they use blades for efficiency.

Positive Displacement Compressors

Positive displacement compression fills a cavity with air and then reduces its volume to compress the air. Positive displacement air compressors are widely used across industries for their reliability and efficiency. They are ideal for precise applications such as food packaging and pharmaceuticals, where consistent pressure is essential.

There are several common types of positive displacement compressor technologies:

Piston compressors

Piston or reciprocating compressors use reciprocating motion to draw and compress air in a cylinder. Available in single-stage, two-stage, and multi-stage designs, they provide flexible pressure outputs suited for diverse industrial needs.

The piston compressor is often found in small-scale uses like refrigeration or automotive air conditioning. Common piston air compressor types comprise single-stage compressors, two-stage compressors, and multi-stage compressors.

Rotary screw compressors

Rotary screw compressors employ interlocking rotors for continuous, vibration-free air compression, making them suitable for demanding applications requiring constant airflow. Many rotary screw compressors incorporate oil-free designs for use in sensitive industries. Most rotary screw compressor types operate smoothly, usually even with vibration-free performance.

Scroll compressors

With two spiralled scrolls, the scroll compressor quietly and efficiently compresses air, a choice commonly seen in HVAC systems for their effectiveness and noise control.

For more in-depth information on air compressors, read our detailed guides and articles.

Applications of Air Compressors

In manufacturing, they are indispensable for assembly lines and material handling processes, while in the medical sector, they supply ultra-clean air for respiratory devices and surgical equipment.

The air compressor remains a vital tool in the household, like inflating tires, air beds, scuba diving equipment, and other inflatables.

Additionally, the air compressor is pivotal for heating and cooling systems, and circulating refrigerant gasses for effective temperature regulation. The air compressor purifies air for gas cylinders used in medical facilities and labs, ensuring safety by removing impurities before further procedures.

Factors Differentiating Air Compressors

Differentiating air compressors goes beyond their operational methods. Several other factors that must be considered are the following:

Oil-injected vs. Oil-free

Not all applications require high-grade, pristine air quality. Consider inflating a tire with “energy air,” where a degree of cleanliness and traces of oil are acceptable. An Oil-lubricated air compressor, also referred to as an oil-injected air compressor, is well-suited for this task due to it’s affordability both at initial purchase and in ongoing operation. They utilise oil as a lubricant to minimise friction and heat within their internal components, including pistons, cylinders, and bearings. These moving vital components need proper lubrication for smooth and efficient operation.

On the contrary, oil-free compressors, or oil-less air compressors, typically employ materials that minimise friction and heat generation, reducing the need for lubrication. They often have advanced cooling systems to manage temperature and ensure efficient operation.

However, in industries involving pharmaceuticals or food, compressed air must meet a range of cleanliness standard protocols, referred to as “active air.” In such scenarios, oil-free compressors are the preferred option, as they generate compressed air that is entirely clean and pure.

Single-stage vs. Two-stage Piston Compressors

When discussing compressors, some factors differentiate them for specific applications. Piston compressors are offered in two variants: single-stage and two-stage models.

Single-stage piston compressors are known for their simplicity and efficiency, using one piston to compress the air in one stroke. They’re great for small tasks needing moderate air. Common in workshops and small industries. However, a two-stage piston compressor is more powerful and versatile. It has two compression chambers and works by compressing air in two steps, giving higher pressure and efficiency than single-stage ones. It is suitable for use in larger industries like manufacturing and construction.

For tasks not demanding constant air supply, the more affordable single-stage version would be enough. Yet, for more powerful tools that require uninterrupted compressed air, a two-stage piston air compressor is a more suitable choice.

Drive Mechanisms

The drive mechanism choice directly affects compressor performance, efficiency, and reliability.

Variable speed drive (VSD): energy-efficient, adapting motor speed to demand, reducing operational costs in industries with fluctuating needs.

Belt Drive vs. Direct Drive

Belt-driven compressors utilise belts and pulleys to transfer motor power to the compressor’s crankshaft. This setup provides flexibility in adjusting speed and power output. The belt and pulley system enables various speed ratios, offering the capability to fine-tune the compressor’s performance to match specific application requirements.

It’s important to note that a belt-driven compressor needs regular maintenance, including belt adjustments and replacements. Direct drive compressors connect the motor directly to the compressor’s crankshaft, enhancing power transfer efficiency and overall effectiveness. Their simplicity and compactness reduce maintenance and failures, simplifying installation and operation. They’re chosen for tasks demanding precise control over speed and power.

Belt-driven compressors excel in reliability, ease of use, cost-efficiency, and power effectiveness. When tasks require speed and power adjustments, direct drive compressors are typically recommended.

Fixed-speed vs. Variable-speed Drives

Fixed-speed compressors run at a steady speed despite varying air demand. The fixed-speed compressor is suitable for applications where the compressed air demand remains relatively stable and predictable. Their upfront cost is lower compared to VSD compressors, making them cost-effective for industries with steady production loads, like automotive manufacturing.

Variable Speed Drive (VSD), or often referred to as Variable Frequency Drive (VFD), compressors offer dynamic speed control, adjusting the motor speed to air volume needs.

Unlike fixed-speed compressors, VSD versions match the compressor’s speed to the actual demand for compressed air. VSD compressors avoid excessive energy consumption during periods of low demand, and reduce operational energy bills over time.

They suit industries with fluctuating demand and precise control needs, such as pharmaceuticals, electronics, and food processing. While the initial cost is higher due to advanced controls, energy savings over time compensate.

The Benefits of Using Air Compressors

An air compressor is notably energy efficient compared to electric tools, delivering consistent performance while using less energy. This reduces your carbon footprint by saving energy and cutting energy costs.

Air tools are also lighter and more versatile compared to electric tools. These lightweight tools can efficiently power a variety of pneumatic tools, allowing you to handle tasks with ease and precision. Air tools are cost-effective and reliable due to fewer moving parts, leading to less frequent maintenance and an extended lifespan. This makes them a valuable investment for professionals and hobbyists alike.

Advanced technologies like VSD further reduce energy consumption, making compressors an environmentally friendly choice.

Conclusion

In conclusion, an air compressor is a necessity across diverse sectors, from manufacturing and construction to automotive and healthcare. From powering pneumatic tools to providing clean and compressed air, air compressors have become vital components of everyday operations. Their efficiency and reliability to generate high-pressure air have made them indispensable across diverse applications. Whether inflating tires or aiding medical procedures, the air compressor provides reliable performance.

Furthermore, technological advancements have significantly improved air compressor performance and efficiency. Incorporating features such as variable speed drives, energy-saving capabilities, and intelligent controls, these machines are now more sustainable and cost-effective than ever. Realising their essential role and choosing high-quality air compressors ensures long-term benefits for a productive and sustainable future.

Need expert advice on choosing the right air compressor for your needs? Get in touch with us by clicking the button below.