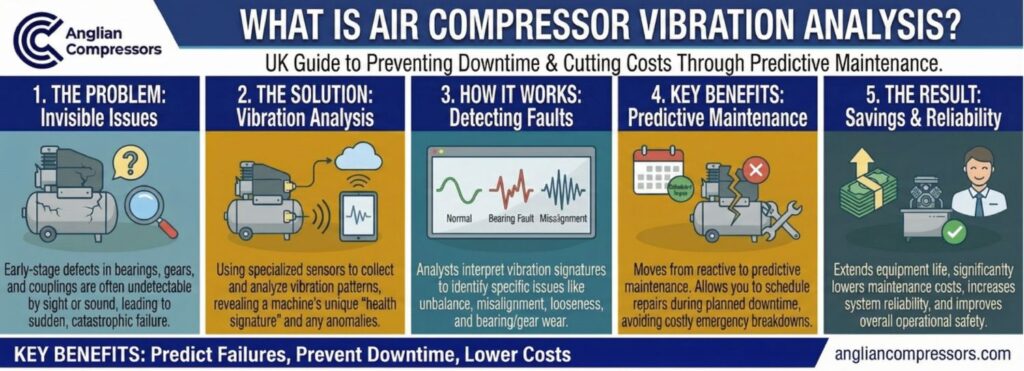

What is Air Compressor Vibration Analysis? UK Guide to Preventing Downtime & Cutting Costs

All operational air compressors experience some degree of vibration. However, subtle, imperceptible shifts in this vibration can serve as an early indicator of developing malfunctions that could halt production. Therefore, vibration analysis is an essairential element of predictive maintenance.

By measuring the machine’s vibrations, it actually becomes possible to detect these warning signs – often months before they would actually start to cause any downtime.

This guide provides a practical framework for UK industry leaders. We demonstrate how the process operates, what it identifies, and how it safeguards your business against unnecessary costs and disruptions.

How Vibration Analysis Works

The process is systematic. It turns subtle machine vibrations into clear, actionable data.

1. Data Acquisition

The process starts by establishing a baseline. A technician captures the compressor’s unique vibration signature while it’s in good condition. This baseline is the benchmark for all future measurements.

- Sensors: Technicians use high-sensitivity accelerometers mounted on critical points like the motor and air-end bearing housings.

- Measurement: Data is captured in three dimensions: horizontally, vertically and axially.

- Integrated Monitoring: Systems such as the Atlas Copco air compressor monitoring system combine vibration analysis with other parameters such as temperature and pressure for a complete picture of health.

2. Data Processing

Raw vibration signals are complex. Analysis software uses a Fast Fourier Transform (FFT) algorithm to simplify them. The FFT breaks the signal into individual frequencies. This creates a simple graph showing clear peaks, which helps diagnose the machine’s health.

3. Expert Analysis

Data is only helpful with expert interpretation.

Our certified analysts use their experience, along with standards like ISO 18436, to distinguish normal operational vibrations from genuine fault signals. The final report shows several key facts, such as a clear health assessment, identification of any faults, and specific repair recommendations.

Common Faults Vibration Analysis Detects

Vibration analysis can pinpoint a wide range of common compressor failures. Each fault has a unique signature.

| Fault Category | Key Vibration Signature | Business Impact |

| Unbalance | A high vibration peak at 1x the compressor’s running speed (RPM). | Accelerates wear on bearings and seals. This reduces efficiency and causes premature failure. |

| Misalignment | Strong peaks at 1x and 2x RPM, often with high axial vibration. | Causes higher friction and energy loss. It can damage couplings and shafts – if left unchecked. |

| Looseness | Multiple peaks at 1x, 2x, 3x RPM, etc. | Leads to component damage from excessive movement and impacts, which can create safety hazards. |

| Bearing Defects | Unique, non-synchronous frequency peaks. | Prevents catastrophic seizure, which can destroy major components and lead to costly rebuilds. |

Vibration Analysis in Numbers

- Up to 20% reduction in energy costs by fixing inefficiencies.

- 12–18 months early warning for bearing defects.

- Prevents unplanned downtime and lost production.

The Business Case: A Smarter Maintenance Strategy

A structured vibration analysis programme delivers clear returns. It helps you move to a data-driven approach to air compressor maintenance.

- Prevent Downtime: Faults are detected early. This allows maintenance to be scheduled during planned shutdowns.

- Cut Costs: Early intervention means smaller and less expensive repairs. It also improves energy efficiency.

- Ensure Compliance: A documented programme provides evidence of proactive maintenance, which helps you adhere to UK regulations like PUWER 1998 and HSE guidance. Data is checked against ISO 10816 vibration limits to assess severity.

- Extend Asset Life: Fixing the root cause of a problem, not just the symptom, reduces stress on the entire asset and helps it last longer.

Compressor-Specific Diagnostics

Effective analysis requires knowledge of specific compressor types.

- Rotary Screw Compressors: In a healthy unit, the main vibration comes from a specific measurement called the Lobe Mesh Frequency. This shows how often the rotor lobes pass the discharge port. (Calculated as LMF = Male Rotor Speed (RPM) × Number of Male Lobes). Changes here can indicate bearing wear.

- Variable Speed Drive (VSD) Compressors: VSDs are efficient but can cause electrical currents that damage bearings. Our advanced diagnostics can detect this specific fault early.

The Anglian Compressors Advantage — A Branch of Atlas Copco

The value of vibration analysis comes from expert application. As an Atlas Copco premier distributor since 1977, Anglian Compressors turns complex data into clear business actions. Our certified engineers have deep knowledge of all major brands. Based in Peterborough, we provide a responsive service across East Anglia and the Midlands.

Book your free vibration health check this month to protect your compressors from costly downtime.