The Role of Compressed Air in Cambridge’s R&D Labs

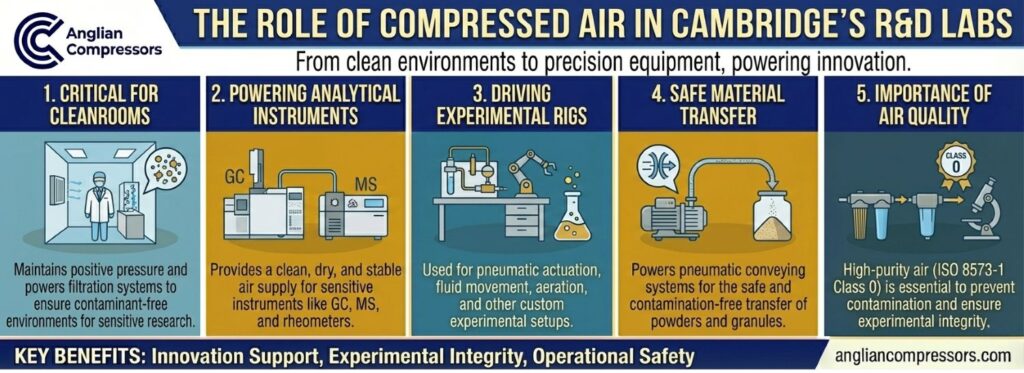

In Cambridge’s innovation cluster, compressed air is more than a utility; it’s essential to research. For labs in biotech, pharmaceuticals, and technology in general, air quality has a direct impact on results. Poor quality air can ruin experiments and damage expensive equipment.

This post covers the key uses of compressed air in Cambridge labs, the required purity standards, and the systems that ensure a reliable quality supply.

Why Air Purity is Critical in R&D

Compressed air underpins the quality and reliability of research in Cambridge labs, and because that air directly contacts samples and instruments, any contamination from particles, water, or oil is a significant problem. As such, maintaining air purity is a fundamental aspect of operational best practices, to protect research results, reduce downtime, and safeguard million-pound equipment.

Key Applications in Cambridge’s R&D Labs

We use compressed air for specific, critical tasks, and it can be found across several locations around the university, including the Cambridge Biomedical Campus and the Cavendish Laboratory.

Life Sciences & Genomics

- Gas Generation: Compressed air is used as feedstock for our on-site nitrogen generation. → Supplies nitrogen of sufficient purity for use in DNA sequencers and to provide inert atmospheres.

- Laboratory Automation: Pneumatic arms and screening platforms are pneumatically powered. → Reliable, fail-safe operation.

- Bioreactors & Fermentation: Compressed air is used to supply sterile air for cell culture growth and to aerate and mix cultures. → Avoids contamination. → Protects high-value batches of cell cultures.

Pharmaceutical & Chemical Research

- Chromatography (GC, LC-MS): Used as a clean carrier gas and for nebulising samples. → Prevents oil contamination that causes false “ghost peaks” and damages detectors.

- Spectroscopy (NMR, ICP): Cools the superconducting magnets and flushes optical paths. → Requires ultra-dry air (down to -70°C dew point) to prevent freezing, which causes irreversible equipment damage.

Advanced Materials & Engineering

- Material Characterisation: Supports frictionless air bearings in rheometers and viscometers. → Prevents particle contamination that causes measurement errors and catastrophic equipment failure.

Meeting Purity Standards: ISO 8573-1

ISO 8573-1:2010 is the international standard classification of air purity. The primary contaminants are:

- Solid Particles: Dust and rust that plug valves and erode parts.

- Water Vapour: Condensation that leads to corrosion and microbial growth.

- Oil: Vapours and aerosols that contaminate samples and mislead instruments.

Class 0 certification, independently tested and verified by TÜV, is proof of no detectable oil contamination. It is the standard required for most pharmaceutical, biotech, and cleanroom applications. Regular compressed air quality testing ensures that standards are consistently met.

Engineering the Right System for Lab Applications

A complete system is required to deliver pure, reliable compressed air.

- Oil-Free Technology: A certified oil-free air compressor is the starting point for laboratories. Labs can explore different types of compressors to find the right fit for their available space and application needs.

- Benefit: Eliminates contamination risk and ensures ISO compliance.

- Variable Speed Drive (VSD): VSD compressors increase and decrease motor speed to match air demand in real time.

- Benefit: Cuts energy costs by 30-50% while providing a stable air pressure.

- Advanced Air Treatment: Desiccant dryers and multi-stage filters remove any water vapour and particles remaining.

- Benefit: Protects sensitive instruments, prolongs compressor life, and ensures process integrity.

- Modular & Remote Systems: Containerised solutions, such as Atlas Copco’s AIRCUBE, offer a complete, external plant room.

- Benefit: Saves lab space, deploys quickly, and can be scaled as needed.

A Practical Approach for Cambridge’s Research & Development Labs

Common issues, such as contamination, high energy costs, and downtime, can halt research in its tracks. A properly designed and maintained system prevents these problems.

- Contamination: Solved with Class 0 compressors and correct filtration, creating a foundation for pharmaceutical-grade air systems for labs.

- Energy Costs: Managed with VSD technology and regular air leak audits.

- Downtime: Prevented with proactive maintenance and remote monitoring tools like SMARTLINK.

- Noise: Controlled with low-noise scroll compressors or acoustic enclosures for a better work environment.

Anglian Compressors, a Branch of Atlas Copco Compressors, understands the infrastructure demands of facilities at Granta Park, the Babraham Research Campus, and the Cambridge Science Park. We provide comprehensive air compressor services in Cambridgeshire to ensure your research never comes to a halt.

Contact Anglian Compressors, a Branch of Atlas Copco Compressors, to book a no-obligation air audit. Our specialists will ensure your Cambridge lab’s compressed air system is compliant, efficient, and future-ready.