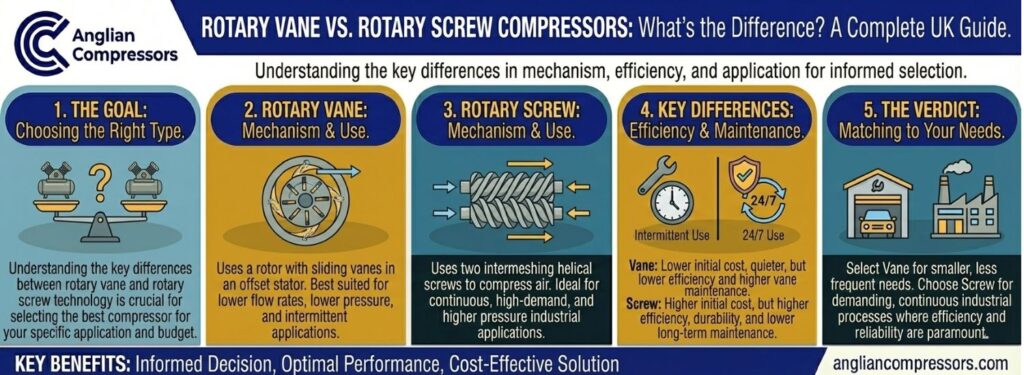

Rotary vane vs. rotary screw compressors: what’s the difference?

When selecting an air compressor for your operation, two of the most common types of rotary compressors are rotary vane compressors and rotary screw compressors. While both deliver compressed air reliably, they differ considerably in terms of energy efficiency, maintenance requirements and suitability for varying air demand.

Rotary screw compressors are widely used for their ability to run at higher speeds, minimise internal air leakage paths and adapt to fluctuating load conditions. Rotary vane compressors, by contrast, house individual sliding vanes that are pushed against the stator wall by centrifugal force. These vane machines are known for their simpler design and lower power consumption in continuous, low-demand applications.

This guide explains how these compressors work, outlines their benefits and limitations, and helps you make an informed decision based on your specific application and operating environment.

What Is a Rotary Vane Compressor?

Rotary vane compressor technology has existed since at least 1874, when a patent for it’s design was first issued. The basic design relies on positive displacement and centrifugal forces for air compression.

The design of this compressor type uses a cylindrical housing and rotary vanes, which are adjustable, on a drive shaft that sits off-centre. There is also both an air inlet and an outlet too. Airtight chambers are created inside the cylinder wall, and as the vanes rotate, a gradually reducing air volume compresses the air.

Many modern rotary vane compressors are oil-lubricated, requiring high-quality lubricants to maintain seals and minimise wear on the vanes and cylinder walls.

The internal mechanism is sometimes oil-lubricated to help maintain airtight seals, but not always. Once compressed sufficiently, the air is transferred to an oil separator. Any remaining lubricant is removed through a further process. Then an aftercooler is used to extract condensation to reduce moisture, or any water present.

Despite the earliest design being over a century old, modernised vane compressors exist because of their design simplicity, effectiveness, and efficiency. However, they are less prevalent than rotary screw compressors due to limitations in efficiency and flexibility for high-demand applications.

What Is a Rotary Screw Compressor?

The rotary screw compressor is a newer technology than rotary vane compressors. It uses two screw rotors, with a pair of drive shafts side by side. There is also the obligatory air inlet and outlet too.

The design relies on the opposing motion of each rotor. There is an intertwining of the rotors as they move as one. The contrary movement has the effect of trapping air between the flutes and the lobes within the rotor’s structure. With the rotors turning together, space becomes more and more restricted, creating compressed air.

Both oil-free and oil-lubricated screw compressors are available:

Oil-free screw compressors: Oil-free compressors, such as Atlas Copco’s Class 0-certified models, are essential for industries like food processing and pharmaceuticals, where contamination-free air is critical. These compressors remove the risk of oil contaminating compressed air, which is requested by the likes of food or pharmaceutical industries.

Oil-lubricated screw compressors: They regulate internal temperatures by sitting the rotors in oil. With the screw compressor lubricated, it runs cooler, creates excellent seals, and reduces potential noise caused by operational friction. These models use a system of filters, dryers, and other methods to remove oil residue and moisture present in the compressed air. Atlas Copco’s GA range features innovative oil-separation systems that minimise oil carryover while maintaining energy efficiency.

Rotary Vane vs Rotary Screw Compressors: What’s the Difference?

Buyers often choose between a rotary vane air compressor and a rotary screw compressor, but they do possess some distinct differences.

Here are the major differences and differentiators to be aware of:

Leakage and Lubrication Needs

Rotary vane compressor air seals are good and improve after the initial installation. However, excessive wear results from the continual movement of the vanes into and out of the rotor vane slot. When this occurs, the air seal becomes less than perfect. Bigger vane compressors use a parallel compressor structure, making them more vulnerable to wear and tear on internal parts.

Lubrication is always required to avoid friction damage and to seal gaps that let air escape. Additionally, there is the risk of sludge accumulation and varnishing of the stator bores when insufficient oil is present. High-quality lubricant is needed to prevent sludge development. Also, lubricants must be changed every 2,000 running hours. This is twice as frequent as with rotary screw compressors.

Rotary screw air compressors do occasionally experience air leakages. However, modern rotary screw compressors operate at high speed and consequently reduce air leakage. Updated designs, including oil-injected versions, aid in creating more complete air seals. Additionally, precision helical part manufacturing for oil-free compressors offers another option to remove air leaks through superior technologically superior manufacturing.

As a rotary screw compressor ages, clearance gaps widen with greater air leakage likely. This is mitigated by maintaining the necessary lubrication to seal the widening gaps.

Uses for Industry

Rotary vane compressors have a horizontal design, making them larger and heavier. While quieter, they are better suited for stationary, lower-demand applications, such as automotive or farming environments. Their small total size and reasonably quiet operation, compared to some other types of air compressors, make them a favourite in industries that value these traits, e.g., farming, and automotive.

Some industries avoid vane compressors, though. This is because of the need for oil and requiring a 100% oil-free compressed air producer. Additionally, where nearby, internal air quality is contaminated, such as in a sawmill, contaminants would eventually cause the vane compressor to seize up.

Rotary screw air compressors are designed to stand vertically. As a result, their footprint is as small as 2 meters by 2 meters (slightly larger when a built-in dryer is needed). Despite this smaller footprint, they still possess substantial compressed air production capability. Their versatility and higher efficiency make them ideal for energy-intensive industries such as food & beverage, pharmaceuticals, and electronics manufacturing.

For oil-sensitive uses, such as in the hospitality or food & beverage industries, oil-free screw compressors are a solid choice. Furthermore, in environments with internally unclean air, rotary air compressor versions avoid the risk of getting clogged up.

Speed Control and Energy Consumption

Rotary vane compressors are restricted to a maximum of approximately 1,100 RPMs due to their use of centrifugal force (a Rotary screw compressor operates up to 3 times faster). Furthermore, it’s vanes are the most susceptible to damage, or excessive early wear and tear, when speed is maxed out. Rotary screw compressors offer advanced energy savings, especially when equipped with variable speed drive (VSD) technology. Atlas Copco’s VSD+ technology can achieve energy savings of up to 60% compared to fixed-speed systems.

Modulating control in theory allows for adjustable speeds, with the latest VSD (variable speed drive) vane air compressors offering around 30 percent energy saving at 5 bar pressure levels. However, businesses wishing to start and stop their vane compressor, as needed for batch jobs, may struggle.

It’s worth noting that operating at artificially lowered speeds prevents a proper seal and allows for internal air leakage. Running above 600 RPM is necessary to obtain a balance between good seals and sufficient centrifugal force to reduce unintended wear on internal parts. Unfortunately, operating at lower RPMs only marginally reduces energy consumption.

Rotary screw air compressors enjoy far greater flexibility on load levels, to as low as 15 percent of the maximum, while automatically adjusting energy consumption to reflect this setting. As a result, energy costs are substantially reduced.

The newer VSD rotary screw compressors benefit from up to 60 percent energy savings under various operational conditions. Improved drive trains and magnet motors, along with oil-cooled compressor technology, deliver further energy savings.

Other efficiency-focused techniques, such as heat recovery, open the door to harnessing the heat generated by compressor operations for space heaters or hot water for bathrooms. This potentially reduces the plant’s total energy costs.

Maintenance Needs – Bearings

Rotary vane compressors use bearings to operate efficiently. Fewer bearings are required than with rotary screw compressors. Also, they are the basic shell variety, where damage is quick to spot and fast to replace.

Rotary screw air compressors lack the simplicity of shell bearings. Instead, they rely on several smaller angular bearings. These are subject to fretting, flaking, and other damage, making it necessary to regularly inspect them.

Maintenance Needs – Other Parts

Rotary vane compressors are simpler to repair, but their vane blades may need more frequent replacements due to wear. This can make long-term maintenance more demanding for high-usage scenarios. It can be inexpensive compared to repairs on a screw air compressor. Another example is bearing replacements, which occur less often and at a lower replacement cost.

Rotary screw air compressors are more complex by design, with repairs necessarily more complicated. Some repairs cannot be performed at the site. Specifically, the rotors are susceptible to damage. Improper or infrequent lubrication may eventually require a complete replacement of the compressor. When repairs are required, on average, they’re more extensive, time-consuming, and costlier than with a rotary vane. However, modern designs minimise bearing wear through enhanced lubrication and precision engineering.

Expected Lifetime vs. Reality

Vane and screw compressors are both designed for long-term use, but their actual lifespan in the real world depends on how they are operated and maintained. Rotary vane compressors typically last between 90,000 and 110,000 hours of operation. Over time, vanes are pushed against the stator wall by centrifugal force and wear gradually, requiring periodic replacement and frequent oil changes to lubricate the moving parts and maintain airtight seals.

A screw compressor features two parallel rotors with minimal clearances between the rotor profiles and the stator, enabling efficient compression. These advanced rotary designs, particularly those from leading screw compressor manufacturers such as Atlas Copco, can operate at higher speeds while maintaining tight internal tolerances. With proper servicing, screw compressors produce reliable, clean delivered air for up to 120,000 hours or more.

While both compressor types are capable of lasting over a decade, screw compressors tend to offer longer-lasting efficiency, especially in variable load conditions, thanks to their superior design and control systems.

Confused About Different Compressors? Talk with Anglian Compressors, a Branch of Atlas Copco Compressors.

Each use case is entirely different. If you’re unsure whether a rotary vane, rotary screw, or another type of air compressor is required, get in touch. We will remove any mystery and assist you in choosing the best one for your needs.

If you are unsure about the best choice for your application, our team at Anglian Compressors, a Branch of Atlas Copco Compressors, is here to assist. With access to Atlas Copco’s extensive product lineup, we provide tailored recommendations for all industries.

Contact us below.

FAQ

What makes screw compressors more efficient over time?

Screw compressors operate at higher speeds and utilise precision engineering, where the external profiles of the rotors meet with minimal clearance. This design, combined with proper lubrication, ensures efficient compression and reduced air leakage over the long term.

Why is regular maintenance important for rotary compressors?

Over time, wear can occur on key components, such as the stator and end covers, or bearings fitted into the stator. Even with high-quality lubrication, it is impossible to eliminate all internal wear, especially where compression equals lost energy. Regular servicing helps maintain performance and prevent avoidable breakdowns.

How do compressor designs affect reliability and service life?

Compressors can last for years if properly maintained, but the design plays a crucial role. In screw compressors, oil is injected into the stator to reduce friction and manage heat. This design, along with closely matched rotor profiles within a cylinder, helps improve reliability and energy efficiency.