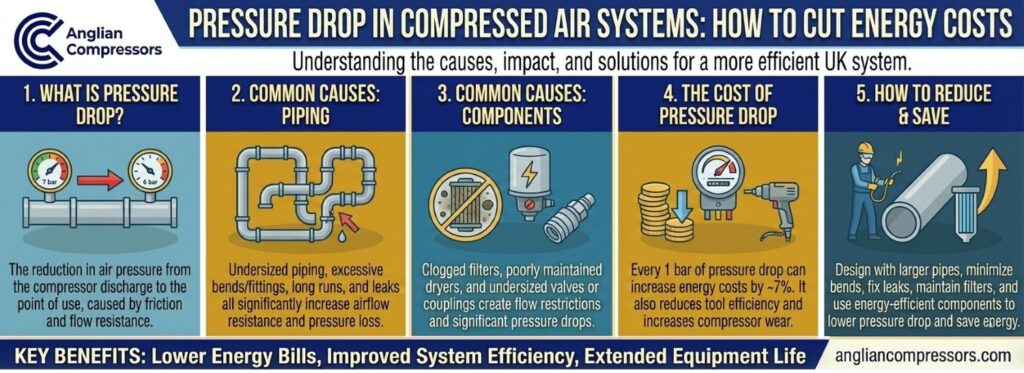

Pressure Drop in Compressed Air Systems: How to Cut Energy Costs in the UK

For any UK business reliant on compressed air, understanding pressure drop in compressed air systems is the first step to cutting energy costs, boosting productivity, and extending equipment life.

This lost compressed air pressure – the difference between the pressure your compressor works to create and the pressure that your tools actually experience – directly contributes to your energy bills, a serious issue considering the high cost of energy for UK industry.

Inevitably, this wasted energy also goes towards surreptitiously slowing production and reducing the life of your equipment.

Industry studies have shown that for every 1 bar (14.5 psi) of “excess” pressure that your compressor must create to overcome these system losses, your energy use goes up by 7%.

The True Cost of Excessive Pressure Drop

The consequences of pressure drop extend far beyond the air lines, impacting financial statements, production output, and capital equipment.

Fixing these issues can lead to typical savings of 5–10% in annual energy bills.

The Financial Drain

The most significant cost is wasted energy. When pressure at a tool is insufficient, the common reaction is to increase the discharge pressure at the compressor.

- A large 75 kW compressor running 4,000 hours a year can incur over £4,200 in pure waste from a single 1-bar pressure drop.

- Even for smaller operations, a 30 kW unit in a light manufacturing plant can waste over £1,600 annually under the same conditions.

Production and Equipment Impact

The costs are not limited to energy bills.

- Productivity Loss: When pneumatic tools receive air below their optimal design pressure, their performance suffers. A 1-bar pressure loss for a pneumatic grinder can reduce material removal by nearly 30%.

- Equipment Strain: Running a compressor at higher pressure than it’s built for wears parts down faster. That means more maintenance callouts and a shorter life for the machine.

- Downtime: If pressure drops too low, the system can’t deliver the air the machinery needs. Production slows or even stops, throwing off schedules and cutting into profits.

Common Causes of Pressure Drop in Compressed Air Systems

Identifying the sources of pressure drop in pneumatic systems requires a systematic evaluation. The causes are often interconnected, creating a cascade of inefficiency.

Piping Issues

A primary cause is friction from undersized piping. Forcing a large volume of air through a small pipe increases its velocity, creating turbulence and significant frictional loss.

The layout is also critical. Long, linear pipe runs with numerous sharp 90-degree bends restrict flow. The single most effective design principle to combat this is a closed-loop ring main, which provides two paths for airflow, halving the distance and reducing velocity.

You can learn more in our guide to compressed air piping systems.

Material and Corrosion

The internal condition of pipework is critical. Traditional black iron or galvanised steel systems are highly susceptible to internal corrosion. Rust and scale on the inside of the pipe make it rough. This increases friction.

Many newer aluminium systems, such as Atlas Copco AIRnet, do not corrode, and have other benefits. They are quicker to install, with no tools required, give a leak-proof fit and give less downtime when altering the system.

It is worth remembering that normal PVC pipe must not be used in UK industrial compressed air systems for safety reasons. It can deteriorate and disintegrate explosively under pressure.

Component Restrictions

Every component added to a system introduces a potential restriction.

- Filters: As a filter becomes loaded with contaminants, the pressure required to push air through it increases. A single, overdue filter can be responsible for up to 50% of a system’s total pressure drop. Learn more by understanding air compressor filtration.

- Dryers: An undersized or poorly maintained air dryer acts as a major bottleneck.

- The “Dirty Thirty”: Often, the most significant losses occur in the final connection to the tool, caused by long, undersized hoses, restrictive couplings, and poorly maintained Filter-Regulator-Lubricator (FRL) units.

Air Leaks

Air leaks are a direct cause of pressure drop. Each leak acts as an unintended point of use, consuming flow and reducing the pressure available for production.

A single 3mm leak in a system can cost a UK business over £1,000 per year in wasted energy. Pinpointing these requires a professional survey, which you can book through our Leak Detection service.

How to Measure and Reduce Compressed Air System Pressure Drop

A professional audit is the fastest way to reduce compressed air system pressure drop. At Anglian Compressors, a Branch of Atlas Copco Compressors, our energy audit process identifies, quantifies, and prioritises fixes.

We place calibrated data loggers at key points to establish precise benchmarks and build a plan for ROI. Identifying and fixing even a 0.5 bar drop can save thousands per year.

Acceptable pressure drop benchmarks across components are:

- Main Piping: ≤ 0.1 bar

- Filters: ≤ 2–3 psi

- Dryers: ≤ 2–5 psi, depending on type

Installing permanent monitoring technology like Atlas Copco SMARTLINK allows for continuous trend tracking, immediately alerting you to new leaks or blockages. This data is the foundation of any plan to reduce your air compressor operating costs.

From Diagnosis to Optimisation: A Systematic Approach

With over 45 years of experience, Anglian Compressors, a Branch of Atlas Copco Compressors, provides a holistic approach to compressed air system efficiency for UK industries including manufacturing, food & beverage, and automotive. Our audits provide a detailed, costed roadmap for achieving maximum efficiency.

For example, one UK manufacturer reduced a 30 psi drop to under 5 psi by replacing undersized piping with 1½-inch AIRnet. The result? 8% decrease in compressor runtime and over £5,000 per year savings.

In addition, system upgrades are reviewed against UK requirements, including the Pressure Systems Safety Regulations 2000 (PSSR). This will help you to meet legal safety requirements and avoid fines. We also help you collect evidence for ESOS and SECR reporting.

Take Control of Your System’s Efficiency

Stop paying for pressure you don’t use. A professional system assessment is the first step toward lower energy bills, higher productivity, and improved reliability.

Book your no-obligation assessment this quarter to lock in lower running costs before energy prices rise again.

You will receive a detailed savings report, and most clients recover the cost in under 12 months.

Contact Anglian Compressors, a Branch of Atlas Copco Compressors, today through our website or by phone to discover how much you could save.