Lowering Costs & Boosting Output: A Guide to Air Compressor Efficiency in Leicester

Why Air Compressor Efficiency is a Strategic Imperative in Leicester

In Leicester and Leicestershire’s dynamic and productive industrial economy, compressed air is the fourth utility. CNC (Computer Numerical Control) machines are essential in precision engineering workshops and the region’s world-class food processing plants and their packaging lines. They do, however, represent a significant operational cost, as the compressed air required to operate them usually accounts for 10-30% of a typical industrial facility’s electricity bill. It stands to reason, then that improving the efficiency of air compressors in Leicester directly increases the profitability, productivity, and sustainability of their respective facilities.

This energy-saving guide outlines the opportunities available for plant managers and energy decision-makers in Leicester to eliminate energy waste and reduce their operating costs. So, gain a competitive edge by better understanding compressed air systems.

The True Cost of Compressed Air: A Hidden Tax on Your Business

The initial cost of purchasing an air compressor pales in comparison to the total cost of owning and operating it for its entire life. Energy is the single most significant expense of operating a compressed air system, accounting for as much as 80% of the TCO. This is not surprising, as compressing air is an energy-intensive task, with 80% of the energy input to an air compressor being converted into waste heat.

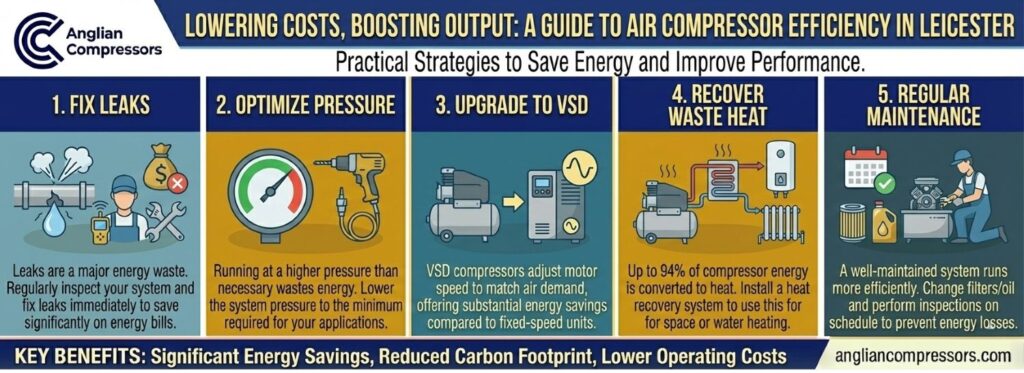

This energy inefficiency is compounded by systemic waste. In unmanaged systems, it is common for 25-50% of all the compressed air generated to be lost through leaks, poor control strategies, and inappropriate use. A 3mm hole in an airline can cost a business over £700 per year in wasted electricity. Eliminating these leaks is one of the highest return investments for SMEs in Leicester, freeing up capital for growth and innovation.

Understanding the Language of Compressor Performance

It’s crucial to measure the right performance metrics to make the best decision. Pressure (PSI/bar), Flow (CFM), and Power (kW) are important, but they don’t give you the complete picture.

Specific Power is by far the most critical metric for assessing energy efficiency. It’s a simple ratio of power used (kW) over the volume of air delivered (usually 100 CFM). Specific Power is often considered the ‘miles per gallon’ of compressed air, as it measures the amount of energy you’re paying for, per unit of air delivered. As trusted voices in the installation and maintenance of Leicester’s compressed air systems, we insist on this information so that we can fairly compare the model we select with any alternative models and brands.

Choosing the Right Compressor Technology for Leicester’s Industries

Your choice of compressor technology is foundational for your business, as it will dictate your facility’s energy costs for years. For the fluctuating demands of modern industry, the system controlling your air compressor is the most critical factor.

- Fixed-Speed Compressors: These units run at a single, constant speed. They are either at full power or idling (“off-load”), where they can still consume up to 70% of their full-load power while producing no compressed air. This makes them highly inefficient for any operation with variable air demand.

- Variable Speed Drive (VSD) Compressors: VSD technology continuously adjusts the motor’s speed to match the facility’s real-time air demand precisely, eradicating wasteful off-load running and delivering dramatic energy reductions.

For Leicester’s diverse sectors, the benefits of Variable Speed Drive (VSD) Air Compressors are clear; the fluctuating demand profiles of advanced manufacturing and the shift-based schedules of food and beverage production are ideal applications. Leading technologies from Atlas Copco, such as the versatile GA FLX range, can reduce energy bills by 35-60%, often delivering full payback on your investment in 12 to 24 months, depending on usage and site conditions. ZR/ZT oil-free VSD compressors produce Certified Class 0 compressed air, making them the perfect fit for applications where there is no tolerance for any form of contamination, such as the pharmaceutical and food packaging industries.

A 7-Point Plan to Maximise System-Wide Efficiency

The path to maximum efficiency is not a simple single machine solution; it’s essential to examine your entire system to achieve maximum energy efficiency, which can result in a 20-50%, or more, reduction in your facility’s energy consumption.

1. Conduct a Professional Air Audit

Effective management begins with accurate measurement. At Anglian Compressors, a Branch of Atlas Copco Compressors, our professional Energy Audit for air compressors utilises data logging and system analysis to create a detailed baseline of your system’s performance, pinpointing specific areas of waste and providing a clear, data-driven roadmap for improvements.

2. Launch a War on Leaks

Air leaks can consume up to 30% of a compressor’s output. Ultrasonic leak detection is the professional standard for identifying them, as it can detect high-frequency hisses that are inaudible in a noisy industrial environment. Follow a comprehensive Detect–Tag–Log–Repair cycle to effectively address this primary source of energy waste.

3. Optimise Your System Pressure

Many systems operate at a higher pressure than necessary. As a rule of thumb, for every 1 bar (14.5 PSI) reduction in system pressure, you can achieve a 7% energy saving. The system should be set to the minimum pressure required by the most demanding application, which also reduces the volume of air lost through any remaining leaks.

4. Master Your Air Treatment

Air that is free from contamination, as specified in the ISO 8573-1 standard, will provide better protection for equipment and ensure product quality. The treatment of air is an energy-consuming process. Rather than over-treating the total output of a system to the highest possible air purity, treat air to the specific standard required at each point of use by using point-of-use filtration.

5. Engineer an Efficient Distribution Network

A piping network that’s too small or not well laid out will create pressure drops, which make your compressor work harder. Its best practice is to use a closed-loop or ring central system and install modern, smooth-bore aluminium piping, such as Atlas Copco AIRnet, to minimise friction and avoid corrosion.

6. Unlock Value with Heat Recovery

Up to 94% of a compressor’s waste heat can be recovered and converted to free hot water or warm air, resulting in a direct reduction in gas and other fuel bills. Heat recovery has enormous potential for Leicester’s food, pharmaceutical, and textile industries, as well as for process water, hot washdowns, and space heating.

7. Implement Proactive Maintenance

Take Leicester Air Compressor Servicing a case in point, and incorporate proactive maintenance into your routine preventative maintenance schedule. After all, no one would use their car without regular oil, filter, and tyre checks. This can be taken one step further by planning regular checks to monitor your system’s energy performance. Products such as Atlas Copco’s SMARTLINK system allow you to remotely monitor system performance, receive alerts for predictive maintenance, and benchmark energy performance against others in your industry, so that you can make smarter, longer-term efficiency decisions. Check out our guide on How to Make Your Air Compressor More Efficient for more useful tips.

Funding Your Efficiency Upgrades in Leicestershire

If your efficiency goals include investing in a brand-new, energy-efficient system, the good news is that with both national schemes, such as the Industrial Energy Transformation Fund (IETF), and tax incentives, such as Enhanced Capital Allowances (ECAs), available to support big-ticket projects, there has never been more support available. Most importantly, these local schemes can provide match funding of between £500 and £10,000, to even SMEs in Leicestershire and Rutland, and offer a funded audit to kick-start the East Midlands Chamber’s Net Zero Accelerator scheme, making your goal of increasing Air Compressor Sustainability more affordable.

Frequently Asked Questions (FAQs)

How much energy can a VSD compressor save?

For applications with fluctuating air demand, a Variable Speed Drive (VSD) compressor typically saves between 35% and 50% in energy costs compared to a fixed-speed equivalent. Advanced models can achieve savings of up to 60%.

What is Specific Power?

Specific Power is the most accurate measure of a compressor’s energy efficiency. It is defined as the power consumed (in kW) per unit of compressed air delivered (typically 100 CFM). A lower Specific Power number indicates a more efficient machine.

Your Partner in Performance and Efficiency

Specialising in compressed air expertise for businesses across Leicestershire, Anglian Compressors, a Branch of Atlas Copco Compressors, is your local authority for making your air compressor more efficient in Leicester. As a major dealer for Atlas Copco, we have access to the highest-efficiency VSD and oil-free technologies available in the UK market. Our engineers are also trained and accredited to service and maintain any make of air compressor, ensuring all local businesses are covered.

Conduct a system audit to identify cost savings and improve efficiency throughout your compressed air system.

Contact us today to book a no-obligation compressed air system audit and receive a clear, data-backed roadmap to boost your bottom line.

Explore our full range of compressed air services at Anglian Compressors, a Branch of Atlas Copco Compressors.