How to Make an Air Compressor Quieter

Running an air compressor can generate a significant amount of noise. Whether it is the compressor intake pulling in air or the exhaust releasing it, much of the noise produced by industrial air compressors comes from the way they operate. If left unmanaged, a noisy compressor can disrupt productivity, increase stress, and pose a long-term risk to hearing health.

Noise from an air compressor can also raise concerns about workplace safety regulations, particularly in environments where multiple units are operating simultaneously. Reducing noise exposure is key to maintaining a safe and comfortable setting. Creating a quieter workspace using sound insulation and other noise reduction techniques helps to improve concentration and overall working conditions.

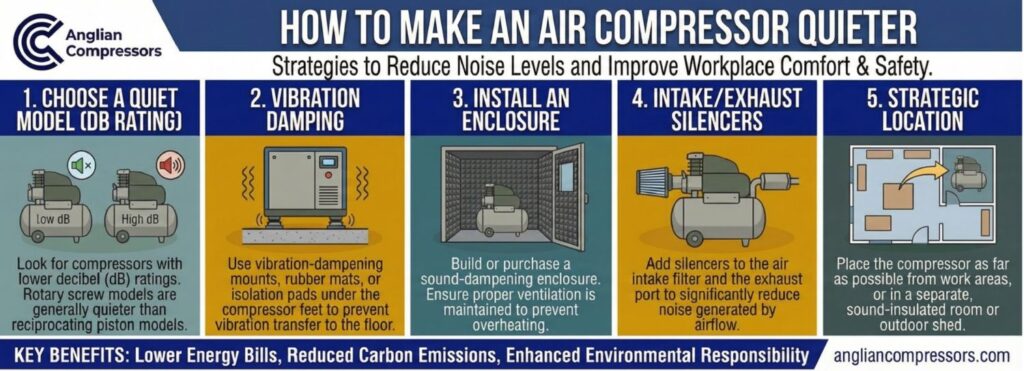

There are several ways to reduce the noise generated around the compressor. These include placing your compressor in a more isolated location, regularly changing your air filters, using acoustic materials, or selecting a quieter compressor model. Whether you are looking to quieten an existing setup or invest in new equipment, the following tips will help you create a more efficient and pleasant environment.

Understanding Air Compressor Noise

Before finding ways to reduce noise levels, it helps to understand where a loud air compressor produces the most sound. Identifying the sources of the compressor’s noise allows you to apply targeted solutions that go a long way to creating a quieter environment.

Much of the noise comes from the following areas:

- Compressor intake and exhaust – the intake draws in plenty of air quickly, while the exhaust releases compressed air under pressure. Together, these can be responsible for the majority of the noise. Placing the intake outside or using a silencer is a reliable way to reduce noise at the source.

- Mechanical operation – moving pistons, motors, and belts in older or oil-free compressor models creates a steady mechanical hum or rattling. Typical rotary screw air compressors tend to be quieter due to their continuous motion and enclosed design.

- Vibrations – as air compressors run, they vibrate against floors and nearby surfaces, which amplifies sound. Isolating the compressor using rubber pads or repositioning it away from echo-prone areas can significantly reduce noise.

- Air flow – as air moves through tubes or pipes, pressure shifts can cause hissing or whistling sounds. Improper air filtration or clogged filters can exacerbate the issue, so proper maintenance is crucial.

Understanding how an air compressor makes noise helps you select the right combination of soundproofing, placement, and maintenance techniques. Whether you need to isolate the compressor, fit a muffler that is right for your system, or simply check the oil level and airflow, each small step adds to the overall noise reduction benefits.

Selecting a Quieter Air Compressor Model

Investing in soundproofing materials and making other improvements reduces sound emanations from existing air systems. However, the most benefit is derived from purchasing a new compressed air system designed with noise reduction in mind.

Modern compressors are significantly quieter than machines produced a decade ago. For example, purchasing a new rotary screw compressor or a scroll compressor sets your business up for success. They will automatically create a quieter work environment. Other implementations to further reduce air compressor noise are worthwhile, too.

When comparing air compressors, pay particular attention to the noise specifications. Each manufacturer confirms what is expected from a new compressor post-installation. Aim for a model with a dB of 75 or below.

Choosing an oil-lubricated compressor for your air system is possible outside of certain industries, such as food and drink production and packaging, pharmaceuticals, or healthcare. These are quieter models compared to oil-free compressors.

For updated advice about the quietest air compressors, speak with our team at Anglian Compressors, a branch of Atlas Copco.

Strategic Placement of the Air Compressor

The positioning of your air compressor is an important decision. While quieter compressors and sound deadening have their place, installing the compressed air system in low-traffic workspaces or a separate, well-insulated compressor room is best.

In some circumstances, the outdoor placement of air systems considerably reduces indoor noise. This requires adequate weather protection to achieve it. Alternatively, moving the air intake outside reduces some contributory noise factors. Rubber soundproofing, where the intake enters through an external wall, further reduces noise.

While creating a quieter working area is important, proper ventilation is critical to avoid overheating. This is especially true when the machine is in a compressor room or another confined space with less natural airflow.

Building Acoustic Barriers

When designing an enclosure or a compressor room, create acoustic barriers to block compressor-related noise.

Dedicated enclosures from heavier materials, like concrete building blocks or drywall, combined with acoustic soundproofing insulation, are ideal.

Using acoustic foam is recommended to dampen sound emanations. Also, sound blankets interior to a physical barrier effectively dampen and absorb noise.

When enclosing compressors for sound dampening, pay particular attention to ventilation openings; otherwise, heat gets trapped and compressor equipment may overheat and become damaged. Therefore, the right approach is venting heat externally while reducing noise internally.

Applying Sound-Dampening Materials

Effective sound insulation adequately reduces the overall noise level. Below are some recommended, affordable sound-dampening materials to consider using:

- Acoustic blankets are convenient to position and flexible enough to cover compressors.

- Mass-loaded vinyl (MLV) sheets block louder sound emanations.

- Foam board insulation is ideal for the lining of enclosure walls.

- Acoustic panels are an alternative material for enclosed wall lining.

Whatever soundproofing material is utilised must be fire-resistant and verified as ‘compressor safe’. Sufficient airflow is always required to prevent overheating.

Installing an Intake Silencer

One of the additional ways to quiet an air system is by installing an intake silencer. Intake silencers work by dampening pulsating noises at a higher frequency that travel through the air intake system.

Installing an intake silencer is relatively simple; they are available commercially or can even be produced as a DIY project using spare materials.

When mulling over a list of sound-dampening options, intake silencers sit near the top for affordability.

Need advice on getting an intake silencer installed? Discuss it with our experienced team at Anglian Compressors, a branch of Atlas Copco.

Minimising Vibrations

Vibration-induced noise is an important consideration.

Below are some practical ideas to reduce the vibration-related noise output:

- Rubber mats fitted beneath an air compressor prevent unwanted floor reverberations.

- Isolation pads or rubber mountings separate the mounting surface and the compressor.

- Tighten up all fittings and bolts to lessen mechanical sounds.

It is easy to overlook vibrations as a noise-generating cause. However, every bit counts because sound bounces off surfaces, echoes, and travels a surprising distance. Moving your compressor temporarily to fit a rubber mat or some isolation pads is worthwhile.

Regular Maintenance Practices

Once noise control is successfully achieved, regular maintenance is required to prevent new noise factors from appearing.

Extra noise is prevented in the following ways:

Regular lubrication – moving parts require lubrication, especially in oil-lubricated compressor technologies. Otherwise, the friction creates additional noise.

Replace intake filters – do not forget to swap out intake filters. With time, these become clogged and contribute to localised noise.

Conduct regular inspections – find and resolve loose connections and tighten screws and bolts. This stops hard-to-track rattling sounds.

As a more general point regarding compressed air equipment, compressors operate more efficiently and enjoy an extended lifespan when they are well-maintained.

Community Insights and DIY Solutions

Below are some other suggestions from the broader community of compressed air producers:

- Quieter, new compressors are superior to sticking with an old compressor and the noise it makes. Soundproofing for ageing equipment is a temporary solution.

- Fibreglass or foam insulation within custom enclosures is an affordable, effective DIY solution.

- Another DIY solution gaining popularity is insulated wooden boxes. These allow for excellent ventilation and avoid trapping heat.

One mistake to avoid is creating a fully sealed solution, like a box or an enclosure. This often leads to compressor damage because of overheating.

Conclusion

Selecting a quieter compressor and strategically installing it away from the main workforce does much to isolate compressor noise. Soundproofing methods, such as acoustic barriers and dampening materials applied to enclosure walls, reduce decibels and how far noise travels.

Lessening vibrations and adding intake silencers reduces the noise of compressed air production. Furthermore, regular maintenance stops small rattles and other issues from increasing the decibels.

Practical methods are appropriate to reduce noise. Custom DIY solutions do help within individualised workspaces. If you are unsure where to begin, our experts at Anglian Compressors, a branch of Atlas Copco, offer professional guidance or a noise consultation for soundproofing solutions.

FAQ

How can I keep my air compressor quiet during regular use?

To keep your air compressor quiet, it helps to combine proper compressor maintenance with strategic placement. Placing the compressor away from work areas, using sound-dampening materials, and ensuring sufficient air circulation all help reduce unwanted noise. A quiet compressor also benefits from clean air filters and regular oil checks.

Is it possible to fit a muffler that is suitable for my compressor?

Yes. You can find a muffler that fits your compressor by checking the model’s intake size and airflow requirements. Intake mufflers are a simple way to prevent noise from spreading throughout your workspace, particularly when combined with other noise control measures.

Should I install my air compressor outside to reduce noise indoors?

Placing the air compressor outside can be an effective way to reduce noise indoors, provided the unit is sheltered from the weather and has access to air. It is also crucial to direct air through tubes or ducts correctly to maintain optimal airflow and prevent pressure loss.