How Compressed Air Powers Northampton’s Logistics: From Energy Savings to 24/7 Uptime

Located at the centre of the UK’s logistics ‘Golden Triangle,’ Northamptonshire provides warehouses with access to 90% of the population in under four hours. Logistics firms newly establishing in the region are harnessing the strategic advantage of key infrastructure links, such as the M1, M6, and A14. They also benefit from links to SEGRO and Panattoni logistics parks, along with significant connections to European markets. However, these firms can only fully utilise the advantages their location provides as long as they can guarantee the uptime, speed, and safety of their businesses; that is where compressed air comes in.

A highly optimised compressed air system enhances safety, productivity, and bottom-line savings, creating a clear competitive advantage. This article examines how compressed air forms the foundation of operations across the logistics hubs in Northampton and provides guidance on maximising the benefits of your system.

Why Compressed Air is the Fourth Utility for Northampton Warehouses

On the M1 corridor, where time is measured in minutes, compressed air is as critical as electricity, water, and gas.

- The Highest Safety: The spark-free operation of pneumatic tools and systems makes compressed air the inherently safer choice around combustible materials, such as cardboard dust. They can also be used safely in wet environments, without the risk of electrocution..

- The Best Reliability: Pneumatic equipment is mechanically simple compared to electrical alternatives. With their fewer moving parts and cooler running temperatures, they are far less likely to overheat, even in constant 24/7 operation. More reliability means compressed air is more highly available and you can expect less downtime.

- Flexibility: A single, well-engineered compressed air system can be used to power a wide range of applications. It can drive heavy-duty tools in the HGV maintenance bay, provide precise actuation on parcel sorting systems, and run automated packaging machinery.

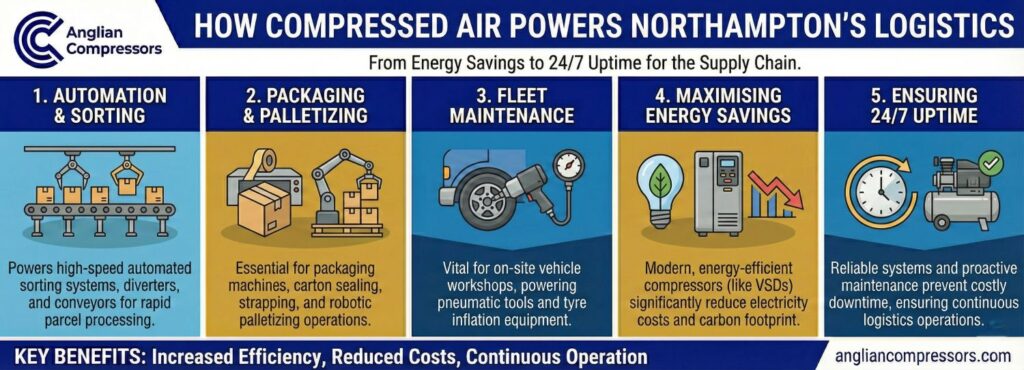

From Conveyors to Packaging: Where Compressed Air Does the Work

From the time goods arrive until the moment they are dispatched, compressed air enables operations to be faster and more accurate.

- Goods-In & Material Handling: Compressed air is used to operate vacuum lifters in the goods-in area, enabling heavy loads to be moved safely and efficiently, and automated dock levellers to create the perfect ‘kiss’ fit with lorries.

- Sorting & Automation: Provides dependable, quiet operation for high-speed parcel sorting equipment, the workhorse of any e-commerce fulfilment operation. Hundreds of pneumatic actuators control diverter gates, which move thousands of parcels per hour with the fast, repeatable actuation force that only compressed air can provide.

- Packaging & Dispatch: Enables automated packaging methods, including carton erectors that use suction cups to create boxes, pneumatic cylinders that apply a consistent sealing force, and “blow-on” label applicators that dispense a measured puff of compressed air to apply shipping labels contact-free.

- Facility & Vehicle Maintenance: On-site vehicle maintenance bays use pneumatic impact wrenches, drills, and grinders to service HGVs and forklifts. Compressed air also makes tyre inflation easy; a vital step to ensuring fleet safety and maximising fuel efficiency.

Choosing the Right Compressor System for Your Warehouse

For a typical 24/7 warehouse in a Northampton logistics park, air demand fluctuates, so selecting and sizing a compressed air system correctly is crucial for achieving both performance and efficiency. An incorrectly specified system can lead to pressure problems as well as significant, and costly, energy waste.

Sizing & Selection Guidance: A Quick Overview

| Compressor Type | Best For | Key Consideration |

| GA (Fixed Speed) | Consistent, steady air demand. | Inefficient if demand fluctuates. |

| GA VSD+ (Variable Speed Drive) | Fluctuating air demand (most warehouses). | Matches motor speed to demand, saving up to 60% in energy costs. |

| ZT/ZR (Oil-Free) | Food, beverage, or pharmaceutical packaging. | Meets strict ISO 8573-1 Class 0 air purity standards. |

- Dryer Selection: A refrigerant dryer (FD series) is recommended for most indoor warehouses, providing a pressure dew point (PDP) of +3°C. A desiccant dryer (MD or CD series) may be necessary for cold storage facilities, or lines equipped with precision valves, to achieve PDPs as low as -20~-40°C to prevent valve icing.

- Piping: A well-planned compressed air piping system is critical in large warehouses. Modern modular aluminium systems, such as Atlas Copco’s AIRnet, minimise pressure drop and allow for easy expansion.

- Storage: Air receivers stabilise pressure and buffer peak demand. A general rule is to size the receiver with 2–5 litres of volume for every cubic metre per minute (m³/min) of system capacity.

- Air Quality: Dryness, one component of air purity standards, is defined under ISO 8573-1. Class 2.4.2 (with 4 representing dryness) is suitable for general warehousing applications, whereas class 1.2.1 is more likely to be required in sensitive food or pharmaceutical packaging applications, and will almost certainly necessitate an oil-free compressor.

Practical Example: Northampton Cold Store

A food distribution centre in Brackmills Industrial Estate is specified with a Class 0 Atlas Copco ZT oil-free compressor, fitted with a heat-of-compression dryer (MD series), to provide -20°C PDP. This will protect against valve icing and deliver food-grade air purity, meeting ISO 8573-1 class 1.2.1 requirements.

Atlas Copco Technology: Efficiency by Design

Logistics air demand fluctuates depending on shifts, sorter cycles, and seasonal peaks. Variable Speed Drive (VSD) technology is the definitive solution to the energy waste of a one-speed system. A VSD compressor, such as the advanced Atlas Copco GA VSD+, continuously matches its motor speed to real-time air demand, so your compressor is never working harder than you need it to.

VSD technology delivers energy savings of up to 60% and is built on key differentiators:

- iPM Motors & NEOS Inverters: The VSD+ models are built with interior permanent magnet (iPM) motors and durable NEOS inverters. The iPM and NEOS combination offers best-in-class efficiency and a wide turndown range.

- SMARTLINK Monitoring: Modern air compressor monitoring systems provide real-time performance, energy, and maintenance data. With SMARTLINK, managers can monitor one compressor, or even a fleet, from a distance, enabling proactive and predictive maintenance that can prevent expensive operational downtime.

- The Ecosystem Advantage: Sourcing the compressor, dryer, filters, AIRnet piping, and controls from a single vendor, ensures perfect system integration and a single-point of accountability. As a premier Atlas Copco distributor in the region, Anglian Compressors has extensive experience designing and installing these highly efficient VSD+ systems in local logistics facilities.

Optimising for Energy, Reliability & Uptime

Compressed air typically accounts for between 10% and 30% of the electricity used in a facility, meaning any hidden inefficiencies in your system can be a massive drain on your profit margins.

The single most significant source of waste in compressed air systems is air leaks. A network of small leaks can easily waste 20-30% of a compressor’s output. Just one 3mm hole in a system can cost a facility more than £1,000 a year in electricity alone. Air leak detection surveys carried out with professional ultrasonic leak detection equipment will pinpoint leaks that can then be repaired. The return on this investment can be seen within months and, in turn, create savings of tens of thousands of pounds per year for a large Northampton distribution centre.

Heat recovery is another method for recovering costs. As much as 90% of the electrical energy used by a compressor is converted into waste heat. Heat recovery units capture this waste energy to provide hot water for bathroom facilities and boost space heating throughout your facility. In this way, previously wasted energy can be converted into a valuable resource.

Navigating UK Compliance and Sustainability Goals

Operating a compressed air system in the UK comes with both legal obligations and increasingly important sustainability targets.

Regulatory Requirements

- PSSR 2000: The Pressure Systems Safety Regulations 2000 legally requires a Written Scheme of Examination (WSE) for most air receivers to be carried out by a Competent Person.

- F-Gas Regulations: The refrigerant used in air dryers is covered by F-Gas regulations, requiring certified personnel for servicing and record-keeping.

- Condensate Discharge: The oil-laced condensate produced by a compressor must be treated by an oil-water separator before it can be legally discharged into the foul sewer.

Sustainability & Energy Reporting

- ESOS & SECR: Data from an efficient, monitored compressed air system provides verifiable evidence for energy reduction strategies under the Energy Savings Opportunity Scheme (ESOS) and the Streamlined Energy and Carbon Reporting (SECR) regulations.

- ISO 50001: A well-managed system directly supports the goals of an ISO 50001 energy management framework.

- Net Zero Alignment: Major developers, such as Panattoni and SEGRO, are building facilities to the highest sustainability standards. An energy-efficient compressor with heat recovery drastically lowers a site’s carbon footprint, aligning with landlord and corporate ESG goals.

FAQs for Northampton’s Warehouse & 3PL Managers

What air quality class is required for my warehouse?

For general warehousing or packaging, ISO 8573-1 Class 2.4.2 may be adequate. If you are dealing with food, beverage, or pharmaceutical applications where compressed air may come into direct contact with the product or packaging, a higher purity class would be required. Often, an oil-free compressor is needed to meet Class 0 for oil, thereby avoiding any chance of contamination.

How much can a leak survey actually save me?

Leaks can account for 20-30% of your compressed air usage, so a survey can help to identify significant potential savings. Fixing just the worst 20% of your systems’ leaks can recover approximately 80% of your wasted energy. This could mean tens of thousands of pounds of annual energy savings for a big distribution centre, for example.

Do I need oil-free air for packaging?

Suppose there’s any chance of compressed air coming into direct or indirect contact with sensitive products (such as food or pharmaceuticals). In that case, oil-free air is the safest option to avoid product spoilage, recalls, and damaging your brand. A proper risk analysis will reveal the specific requirements for your industry.

Is VSD(+) worth it for a warehouse that runs 24/7?

Absolutely. Even in a 24/7 operation, air demand fluctuates based on shift patterns, automation cycles, and breaks. A fixed-speed compressor is highly inefficient during these periods of lower demand as it will run at maximum capacity at all times. A VSD compressor, on the other hand, precisely matches output to demand, delivering significant energy savings that typically provide a rapid return on investment.

What size air receiver do I need?

The right size depends on your peak demand, the type of compressor, and your control strategy. A common starting point is to have 2-5 litres of receiver volume for every m³/min of compressor capacity. A professional system audit is the best way to determine the optimal size to ensure stable pressure and maximise efficiency.

Your Partner for Peak Performance in Northampton

Anglian Compressors, a Branch of Atlas Copco Compressors, has been a technical partner for businesses throughout the region for over 45 years. Our knowledge of the logistics industry enables us to supply solutions that help you optimise your performance and increase profits. As an Atlas Copco distributor, we offer professional installation of world-class systems.

Our local engineers also provide comprehensive Air Compressor Servicing in Northampton for all major brands, including Kaeser, Ingersoll Rand, Gardner Denver, and BOGE. We offer vital 24/7 emergency call-outs to keep your 24/7 operation moving and provide expert retrofit services to upgrade your existing system with master controllers or modern piping.

Don’t let wasted energy or the risk of downtime compromise your competitive edge. Contact our team today at [01733349993] or book online. We will help you uncover hidden savings and ensure your facility is powered for success.