Compressed Air’s Role in Northamptonshire’s Motorsport & Automotive Engineering

It’s probably the only county in the UK with its own moniker, Northamptonshire is the pulsating heart of what is known as “Motorsport Valley”, a high-tech cluster where speed is everything and where relentless, ground-breaking innovation is the name of the game. For the teams competing in F1, the engine manufacturers, and other precision suppliers servicing them, achieving success is all about microns and milliseconds, maximising uptime, and minimising any time lost.

The consequences of this continual push forward are extraordinary for all infrastructure within the area, and not least the oft-forgotten fourth utility, compressed air. A fail-safe, high-quality supply of compressed air is absolutely mission-critical if companies operating in this environment are to deliver the precision, quality and speed on which the industry is built.

The Heart of High Performance: Why Motorsport Valley is Different

The intense competition within Motorsport Valley creates a high-stakes environment with zero tolerance for downtime or quality deviation. A system failure doesn’t just halt your production line; it could delay a critical performance upgrade to a car. Failure to implement an upgrade on time for a race can cost a team millions.

That’s why compressed air systems are designed and maintained from Brackley to Silverstone by local specialists such as Anglian Compressors, a Branch of Atlas Copco Compressors, to ensure maximum uptime. Consequently, any industrial utility provider becomes a critical performance partner whose reliability and technical expertise are integral to a client’s competitive strategy. Investing in high-performance motorsport compressed air systems is an investment in on-track success.

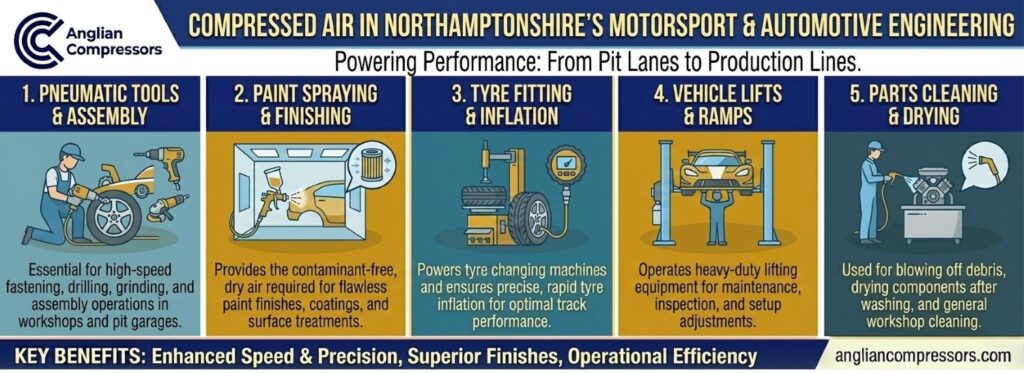

Critical Applications: From CNC Machining to the Flawless Finish

Compressed air touches every corner of production and is fundamental to the performance and safety of the finished car.

- Assembly & Automation: Impact wrenches and air ratchets are used due to their high power-to-weight ratio, minimising operator fatigue and speeding up production cycles. Robotics are used for high precision, high speed and high force applications, like welding, lifting, and complex part assembly, which are driven by compressed air.

- CNC Machining: Cosworth’s and Ilmor’s machine shops utilise compressed air for automatic tool changing and spindle lubrication, both of which occur at high speeds. But most importantly, compressed air is used to blow chips and other contaminants away from the workpiece. A single particle caught between the tool holder and the spindle can damage multi-thousand-pound components and ruin machining accuracy.

- Paint & Finishing: The paint finish on an F1 car isn’t just cosmetic; it’s an aerodynamic component. Air purity is critical across the blasting, blow-off, and paint atomisation stages. Any contamination from oil or water can cause defects, such as “fisheyes,” which ruin the finish and measurably increase drag or reduce downforce. This makes oil-free compressors for paint shops a non-negotiable requirement in F1.

| Application Area | Compressed Air Function | Air Quality Requirement |

| Assembly Tools | Powering pneumatic tools | Consistent pressure |

| CNC Machining | Blow-off, lubrication | Clean, dry air (Class 2.4.2) |

| Paint Shops | Atomisation, blow-off | Class 0 oil-free |

| Pit Stops | Wheel guns, jacks | Instant high-flow pressure |

| Wind Tunnels | Stable airflow generation | Clean, dry, stable |

| Composite Curing | Autoclave pressurisation | Dry nitrogen or air |

Elite Applications: From Wind Tunnel to Victory Lane

Beyond the factory floor, compressed air becomes a vital, performance-enhancing technology.

- The Sub-Two-Second Pit Stop: The F1 pit stop is the ultimate pneumatic challenge. Bespoke, high-powered wheel guns and pneumatic jacks demand an instantaneous, high-pressure, and high-flow supply of air or nitrogen with absolute reliability. A fractional drop in pressure can cost a team track position.

- Wind Tunnels: Aerodynamic development relies on wind tunnels where vast volumes of pressurised air generate the required laminar airflow through the test section. The quality of this air supply is directly proportional to the accuracy of the aerodynamic data. Leading technology providers are essential; Atlas Copco UK air compressors (specifically their oil-free models) are used in global benchmark wind tunnels like Windshear in the US, validating their trustworthiness at the elite level.

- Composite Curing: The carbon fibre monocoque chassis, wings, and bodywork of an F1 car are cured in an autoclave. This industrial pressure vessel utilizes compressed air or nitrogen to ensure that layers bond perfectly, resulting in parts with maximum strength and minimal weight.

The Technology Driving Performance and Compliance

For Northamptonshire’s engineering leaders, achieving success requires optimised systems that deliver purity, efficiency, and reliability.

Air Purity: The Class 0 Imperative

The air drawn into a compressor contains water, oil vapour, and solid particles. If left untreated, these contaminants can damage tools and compromise the quality of the end product. To manage this, international standards define air purity. For sensitive applications such as painting, ISO 8573-1 Class 0 is the most stringent classification, ensuring 100% oil-free air. This is achieved using specialised oil-free compressors paired with filtration and drying equipment. These standards are essential for safe, compliant operations under the UK’s Pressure Systems Safety Regulations (PSSR) 2000, which mandate a Written Scheme of Examination (WSE) must be produced, one of the key compliance services Anglian Compressors, a Branch of Atlas Copco Compressors, delivers.

Energy Efficiency with VSD

Compressing air is an energy-intensive process that often accounts for a significant portion of a facility’s electricity bill. In the world of Formula 1, where a strict cost cap governs spending, operational efficiency is a direct competitive advantage. Traditional fixed-speed compressors operate at full speed even during periods of low demand, resulting in wasted energy during idle cycles. Variable Speed Drive (VSD) air compressors address this issue by adjusting the motor’s speed to match demand precisely, resulting in up to a 60% reduction in energy consumption. Every pound saved on energy is a pound that can be legally reallocated to car development.

Sustainability & Heat Recovery

Optimising a compressed air system directly supports sustainability goals.

- A VSD rotary screw compressor, commonly used by UK businesses, combined with proactive Leak Detection for Air Compressors, drastically reduces a facility’s carbon footprint. Proactive leak detection audits can recover up to 30% of lost compressed air energy, often paying for themselves within months.

- Heat recovery systems can capture and reuse the 94% of energy used to operate an air compression system, which is converted into waste heat. This “free” heat can be used for hot water or space heating, lowering heating bills as well as CO₂ output.

- On-site nitrogen generators for motorsport tyre inflation eliminate the transport-related emissions associated with bottled gas deliveries.

- These initiatives help businesses align with sustainability frameworks, such as ISO 50001, and the UK’s Net Zero 2050 targets.

Uptime Through Smart Technology

Unplanned downtime is not an option. Equipped with IoT (Internet of Things) technology such as Atlas Copco’s SMARTLINK, innovative compressors monitor key operational parameters in real-time. This valuable data can be used to predict maintenance needs and identify potential failures before they occur. Adopting this predictive maintenance approach protects production schedules and ensures that an essential piece of kit is never late for its freight deadline for the next race.

Your Performance Partner in Motorsport Valley

Performance at this level takes more than equipment; you need a strategic partner with the expertise and experience to design, install, and maintain your critically important compressed air system. Anglian Compressors has been the leading distributor for Atlas Copco in the UK and Ireland since 1977, so not only do we understand your sector’s needs, but we have the technical ability to meet them. The fact that Atlas Copco and the Red Bull Ford Powertrains “Smart Factory” are working together is the ultimate seal of approval.

Anglian Compressors, a Branch of Atlas Copco Compressors, provides a comprehensive suite of services designed to maximise uptime. This includes professional air audits, designing efficient compressed air piping systems, and providing preventative maintenance programs. For a real-world example of our work, review the Brinkley-Propeller case study, which details our installation of an Atlas Copco GX11 and AIRnet piping in a fast-turnaround aviation and motorsports repair facility. Our expert team of certified engineers provides professional air compressor servicing across Northamptonshire, offering a responsive 24/7 breakdown service to ensure uninterrupted operations. All systems are maintained in line with UK compliance standards, including the Pressure Systems Safety Regulations (PSSR) 2000 and ISO 8573-1.

With over four decades of experience in compressed air, and trusted by global and regional leaders alike, Anglian delivers motorsport-grade reliability to businesses across Northamptonshire.

We conduct on-site surveys, deliver turnkey installations, and offer responsive support across the county, including Brackley, Silverstone, Kettering, and Wellingborough.

Contact the Anglian Compressors, a Branch of Atlas Copco Compressors, to schedule an audit and discover how an optimised compressed air system can become your competitive advantage.