Compressed Air Solutions for Breweries: From Packaging to Fermentation

For UK breweries, an often-overlooked utility dictates product quality and operational cost: compressed air.

It can account for over 20% of a facility’s total energy bill, and a single contamination event can spoil entire batches, costing thousands.

Malt, hops, and yeast rightfully get the attention of brewers, but your air system that breathes life into your operation can be the difference between a perfect pint and a costly recall.

This guide to Compressed Air Solutions for Breweries: From Packaging to Fermentation details the technical and efficiency strategies needed to protect your product, maintain compliance, and boost your bottom line.

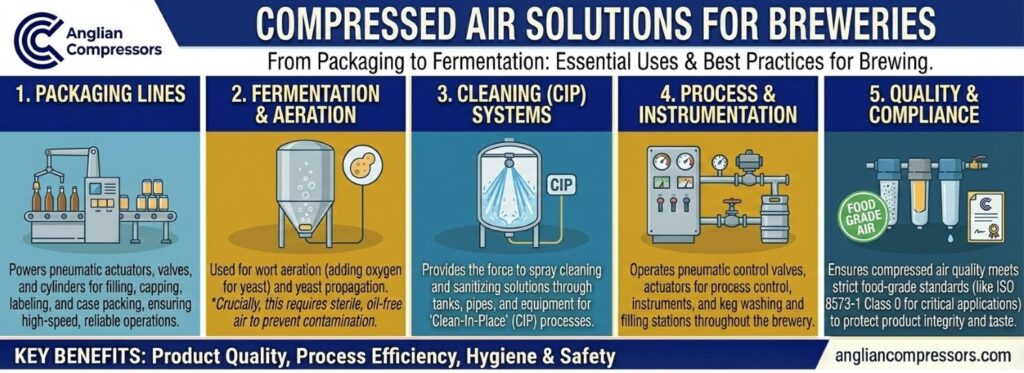

The Critical Role of Air Quality in Every Brewing Stage

From the moment raw materials arrive to the final packaging, clean compressed air is the invisible force driving your brewery’s key operations. Poor air quality at any stage introduces risk.

- Raw Material Handling: Compressed air is used to pneumatically convey grain in a hopper. Dirty air will contaminate the grain with moisture or microbes before brewing even starts.

- Brewhouse Operations: Compressed air runs the valves that move wort (unfermented beer) and hot water through the system. When pressure dips or spikes, batches can lose consistency. Sometimes it’s just a slowdown. Other times, it throws the whole schedule off.

- Fermentation and Aeration: This is the most critical direct-contact application. A precise amount of sterile, Class 0 oil-free air is injected into the wort to promote healthy yeast growth. Oil contamination at this stage is toxic to yeast. Fermentation will stall and produce off-flavours that can never be removed.

- Packaging Lines: Compressed air is used to purge every bottle, can and keg to remove oxygen and moisture. Oil residue at this point will instantly kill the beer’s head retention, resulting in a flat, unappealing product for the customer.

- Cleaning and Sanitation: Compressed air powers high-pressure Clean-in-Place (CIP) systems. The air must be clean to avoid re-contaminating freshly sanitised lines.

Understanding these risks is central to designing effective Air Compressors in the Food and Beverage Industry.

Protect Your Beer with Oil-Free Class 0 Air

Controlling air purity is non-negotiable for brand protection. To manage contamination risks, the industry relies on the ISO 8573-1:2010 standard, which classifies air based on three contaminants. For breweries, the target is Class 1.3.0.

- Particles (Class 1): Specifies a particle count low enough to prevent microbial contamination.

- Water (Class 3): Corresponds to a pressure dew point of -20°C, a level of dryness that makes it impossible for bacteria to grow.

- Total Oil (Class 0): The highest and most stringent class. This class certifies that the air is totally free of oil aerosols and vapour, thus removing the risk of contamination at source.

Compliance to this standard is required for food safety audits such as BRCGS and to meet HACCP regulations where compressed air is a critical control point. It is also required for UK law, such as the Pressure Systems Safety Regulations 2000 (PSSR 2000).

Designing a Reliable and Compliant Brewery Air System

A highly efficient system is more than an efficient compressor. System design must ensure a reliable supply of pure dry air.

[Note to publisher: A simple diagram could be inserted here showing compressed air’s role from raw materials to packaging.]

The TCO Advantage of Oil-Free Technology

While an oil-lubricated air compressor may have a lower purchase price, its Total Cost of Ownership (TCO) is significantly higher due to the ongoing costs of filtration, maintenance, and the ever-present risk of contamination.

An oil-free air compressor guarantees Class 0 air. The higher initial investment is quickly recovered through major energy savings, lower maintenance, and zero risk of a batch-destroying oil leak. The payback period for switching to an oil-free model can often be under two years.

Essential Air Treatment and System Design

Pure air from the compressor must be kept pure.

- Drying and Filtration: A system of Compressed Air Dryers is essential to remove all moisture. For direct-contact applications like wort aeration, point-of-use sterile filters are not optional—they are a final, essential barrier against microbes.

- Piping and Redundancy: Pipework made from non-corrosive aluminium or stainless steel, laid out in a “ring main” design, ensures stable pressure. Proper condensate management is vital. Without it, moisture can leak into the system and cause bigger issues down the line. Redundancy helps too—a backup compressor means that when maintenance or a breakdown happens, production doesn’t have to stop.

On-Site Gas Generation: Taking Control of Your Supply

Many breweries are taking control of their gas supply to escape volatile pricing and delivery issues.

- Nitrogen: An on-site generator ties into the compressed air system. It produces high-purity nitrogen for inerting tanks and for achieving a consistent pour. Learning How Does a Nitrogen Generator Work? also shows where breweries can save money over time.

- CO₂ Recovery: These systems collect the carbon dioxide released during fermentation. The gas can then be reused for carbonation instead of being lost. That means fewer purchases and a smaller environmental impact.

Maximising Efficiency and Slashing Operational Costs

Energy accounts for over 80% of a compressor’s lifetime costs. Making your system more efficient is one of the fastest ways to boost your brewery’s profitability.

Proven strategies to How to Make Your Air Compressor More Efficient include:

- Variable Speed Drive (VSD): This technology automatically matches the motor speed to your brewery’s fluctuating air demand, cutting electricity use by 35–50%.

- Heat Recovery: An energy recovery system can reuse up to 94% of a compressor’s waste heat to pre-heat water for your CIP system or cask washing, lowering your heating bills.

- Leak Detection: Air leaks can silently waste 20–30% of your generated air. A professional audit pinpoints this waste for immediate savings.

A craft brewery in East Anglia recently reduced its energy consumption by 40% after implementing a VSD compressor and a heat recovery system. For a medium-sized UK brewery, these measures could save £10,000–£20,000 annually.

Your Specialist Partner for Brewery Compressed Air

The complexity of designing a brewery-specific system requires specialist expertise. As an Atlas Copco Premier Distributor with decades of experience in the UK brewing sector, Anglian Compressors understands how to design, install, and maintain systems that guarantee quality and compliance. Our engineers have deep knowledge of food safety standards and can help you meet your BRCGS and HACCP obligations.

The first step towards a more reliable and efficient system is a data-driven assessment.

Book your brewery compressed air audit with Anglian Compressors, a Branch of Atlas Copco Compressors, to uncover hidden inefficiencies and contamination risks.

Speak to our brewing air experts to design a Class 0, compliance-ready system.