Common Air Compressor Failures and How to Prevent Them

Many business facilities depend on air compressors operating as expected. Downtime is damaging to productivity, production levels, and profitability.

There are various potential causes for compressor failures. These include inadequate ambient air, overheating, leaks, or part failure. Preventive maintenance avoids many problems, making it easier to resolve any that occur.

Here are seven of the most common air compressor failures and how to prevent them.

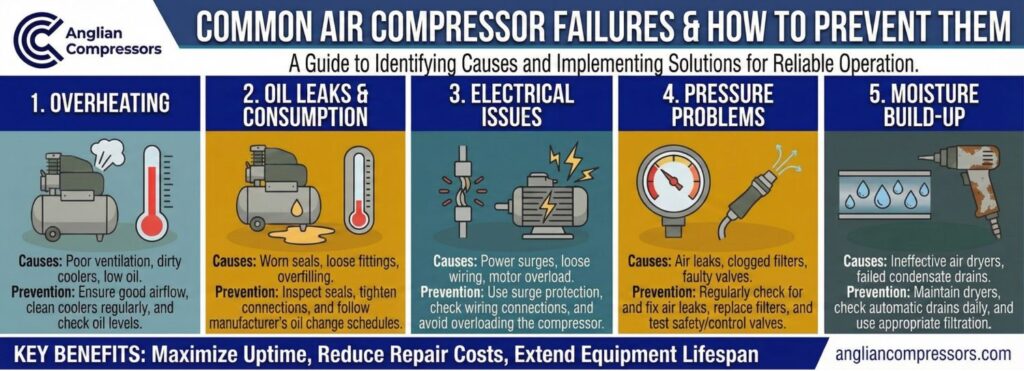

Electrical Issues

Compressor shutdowns caused by an electrical issue are common. It could be faulty wiring, corroded fuses, or damaged contactors.

As a result of power surges or voltage irregularities, your compressor may shut down. Either can scramble control boards or damage motors.

A major electrical failure or fault creates related knock-on effects. These include internal component damage, acid buildup, and potential compressor overheating.

An overloaded motor can happen when a restart occurs suddenly and immediately after a power loss. This happens when a soft-start is either not enabled or not available.

Prevention Tips:

- Check all the electrical wiring and the connection terminals regularly.

- Put powerful surge protectors in place. Use phase monitors to scan for level changes.

- Add electrical testing to the scheduled planned maintenance.

Air Leaks

Air leaks lead to lost pressure and reduced airflow in a compressed air system. The high air pressure level eventually finds the weakest link in the system or distribution chain. As a result, leaks are commonly discovered at the joints or couplings, valves, or in one of the many hoses.

Leaks create significant energy losses as one of the more common air compressor problems. Compressors operate longer or more often to compensate, adding extra wear and tear to the machinery.

Air escaping is not always audible, especially in a noisy workspace. However, they are detectable through pressure drops in the system. Also, diagnostic tools can isolate them.

Prevention Tips:

- Schedule a regular leak detection survey. Use an ultrasonic detector to isolate air leaks. One low-tech option is to create soapy water using liquid soap and water. Then lather it over potentially affected areas. This produces bubbles when air is released.

- Replace weathered hoses and ageing fittings. Tighten up the remaining fittings to prevent air leakage.

- Document where leaks were found. Match new leaks to previous ones to determine whether leaks are recurring in the same places.

If you would like a professional to take a look, schedule an air leak audit with Anglian Compressors, a Branch of Atlas Copco Compressors.

Overheating

Overheating is a significant cause of compressor damage. It can occur because of dirty air filters, blocked coolers, inferior ventilation, and hot ambient air temperatures.

Regular overheating adds excessive, premature wear to valves, seals, and lubricants. When not spotted, this impacts compressor performance and reduces the life of your compressor.

Inadequate oil levels or reduced oil quality cause a compressor to overheat. Using inferior, non-recommended oil is far costlier in the long run.

Prevention Tips:

- Ensure sufficient physical space for clear airflow all around the machine. Regularly cleaning the coolers prevents the engine from overheating.

- Verify that the cooling fan is operating as expected – does it need cleaning or replacing?

- Check oil levels to verify enough lubrication – refill as needed.

- Be mindful of rated duty cycles. Do not overload the compressor by operating it beyond capacity.

Oil Leaks

Oil leaks are a common problem, but not always easy to spot. It is not unusual to discover oil leaking because of overfilling during the last scheduled maintenance. Alternatively, leaks at the drain valves, gaskets, or oil seals are common.

The only indicator of an oil leak may be a slick puddle on the ground or a drop in compressor performance.

Leaking oil is problematic. Other than being a safety hazard, it voraciously accumulates grime and dust. This adds accelerated wear to any components it comes into contact with.

Prevention Tips:

- Check oil levels to verify that they meet expectations.

- Verify if the oil quality and overall condition are satisfactory.

- Stick to the best oil-grade supplies. Do not use the wrong oil – the wrong oil viscosity affects performance and accelerates wear.

- Refill oil based on the compressor’s guidelines.

- Swap out worn seals and ageing gaskets during the air compressor service.

Pressure and Flow Problems

A variety of issues cause insufficient air pressure and airflow.

The air intake filters may have become obstructed, preventing enough ambient air from flowing into the compressor. The regulators may be failing. Also, improper flow settings are a possibility.

Fluctuating air pressure can damage pneumatic air tools and contribute to production delays. Some equipment is more sensitive to pressure fluctuations than others. Insufficient airflow may cause some tools to stop working, whereas others are unaffected.

Pressure switches are another potential issue. They can become too worn or start malfunctioning. Either problem will interrupt smooth compressor cycling processes.

Prevention Tips:

- Check and replace intake filters when needed.

- Make adjustments to regulators for your system needs.

- Run periodic tests of safety valves and pressure switches to prevent unexpected failures.

Contamination

Major contaminants are troublesome for any commercial air compressor. Oil, dirt, and moisture are typically the worst offenders.

Product quality is badly affected. When remaining present in compressed air, they begin to corrode distribution pipe networks and internally clog up power tools.

Poor maintenance of air filters and air dryers leads to accumulated contaminants.

Prevention Tips:

- Multi-stage filtration is ideal for preventing issues. It must be specific for your compressor, not an ad hoc solution.

- Drain separators and moisture traps daily; otherwise, they result in overflows or blockages.

- Add dryers to the maintenance servicing schedule. If replacing filters is not included, also add these to the schedule. Ensure there are sufficient replacement parts available.

Improper Maintenance Practices

Adopting inferior or incorrect maintenance practices risks doing more harm than good.

Skipping maintenance cycles or using the wrong compressor parts eventually leads to cascading failures, creating substantial downtime.

Service intervals get missed when not logging all maintenance actions as a standard practice. Shortcuts only hurt later.

Poor staff training in operations and equipment care is a major issue.

Prevention Tips:

- To ensure your compressor keeps running, use a manufacturer-recommended air compressor maintenance plan.

- Train operators based on established best practices and daily equipment analysis.

- Maintain accurate service logs and use preventative maintenance to avoid remaining only in a reactive mode.