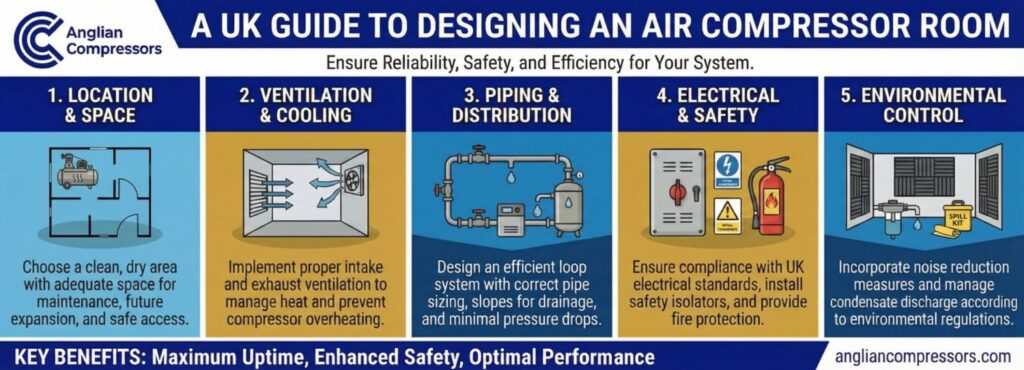

A UK Guide to Designing an Air Compressor Room for Reliability, Safety, and Efficiency

The air compressor room is the heart of your industrial facility, and its design directly impacts energy costs, reliability, and safety. Given that compressed air can account for up to 30% of a facility’s electricity consumption, getting the design right directly protects your bottom line.

A well-planned compressor room is a high-performing asset, rather than just another utility space, and this guide will provide a framework for designing an energy-efficient compressor room that boosts productivity and meets all relevant UK regulations.

Location, Space, and Foundation

Your room’s physical structure is fundamental, and making the right decisions here prevents future operational headaches and unnecessary costs. That’s why the experts at Anglian Compressors, a Branch of Atlas Copco Compressors, provide a service to help you plan the optimal layout for your specific needs.

- Strategic Location: A central compressor room is best practice, and a good location will lower costs by minimising pipe runs and expensive electrical cabling. It also ensures the system draws in cool, clean intake air, which is essential for performance.

- Sizing the Space: A cramped room makes maintenance difficult and expensive.

- Maintenance Access: Plan for 1 to 1.5 metres of clearance around your equipment to ensure technicians can work safely and efficiently, and reduce overall service time.

- Future-Proofing: Reserve 25–40% of extra floor space to allow you to add equipment later without worrying about a costly redesign.

- A Solid Foundation: A solid, level foundation is non-negotiable as it’s vital to preventing vibration that can lead to premature component wear and costly breakdowns.

Ventilation and Air Quality

Proper ventilation in your compressor room is critical for reliable and efficient operation.

- Heat Management: Learning how to extend your compressor’s lifetime with the right environment starts with effective temperature control. High ambient temperatures will reduce your compressor’s efficiency, increase your energy bills, and can lead to unexpected shutdowns.

- Ventilation Design: You will need to provide some kind of forced ventilation in almost all circumstances in an air compressor room, as it maintains a constant flow of cool air, which will carry heat away from your system. This keeps your equipment running at its highest efficiency and lowers your chances of any overheating.

- Ducting: Duct the hot exhaust air directly outside and ensure that your ducting is appropriately sized to prevent creating backpressure and voiding manufacturer warranties.

System Layout and Pipework to Optimise Airflow

Designing your compressor room with a logical layout will simplify maintenance and boost performance. The equipment sequence should be: Air Compressor → Wet Receiver → Filters → Dryer → After-Filters → Distribution System.

When designing efficient air compressor piping systems, a “ring main” configuration is the most effective. This design provides stable and consistent air pressure to all points of use, protecting your tools and ensuring consistent product quality.

Why Proper Room Design Matters for UK Businesses

A strategic design will help you achieve significant energy savings and enhance equipment reliability, resulting in less downtime and the assurance of knowing your room is compliant.

UK Compliance and Safety

There are legal responsibilities associated with running compressed air systems in the UK, and failure to meet them can result in substantial fines, forced production shutdowns, and very real safety hazards.

Pressure Systems Safety Regulations 2000 (PSSR)

A system cannot be legally operated without a “Written Scheme of Examination” (WSE); you need a formal safety inspection plan certified by a “Competent Person” before you can switch your system on.

Condensate Management

The oily water produced during compression is hazardous waste, and it is illegal to discharge it untreated. A compliant oil-water separator is mandatory to avoid environmental fines.

Noise Control

Compressors can exceed 85 dBA, the legal limit at which employers must take action to protect their employees’ hearing. As such, your room design should incorporate acoustic barriers and noise attenuation to create a safe work environment.

In industries such as food, pharmaceuticals, or electronics, for example, compliance also includes air purity requirements, such as ISO 8573-1 Class 0 (oil-free compressor).

Unsure about your PSSR obligations? Contact Anglian Compressors, a Branch of Atlas Copco Compressors, for a compliance check.

As a premier Atlas Copco distributor since 1977, Anglian Compressors, a Branch of Atlas Copco Compressors, has the expertise to act as the Competent Person for your WSE, turning a complex legal requirement into a simple, managed service for your peace of mind.

Designing for Long-Term Efficiency and Value

Energy can account for up to 70% of the lifetime cost of owning your compressor, so efficiency is crucial to profitability.

- Energy-Efficient Compressors: Variable speed drive (VSD) compressors reduce energy bills by precisely controlling motor speed to meet your exact air requirements.

- Heat Recovery: Up to 94% of the energy consumed by a compressor is lost as waste heat, but heat recovery systems can capture that waste energy to heat water or your facility. Heat recovery systems have a short payback period and are a great way to optimise your energy usage.

- Intelligent Monitoring: Atlas Copco SMARTLINK continuously monitors and reports on system performance in real-time, helping you to optimise your energy use and prevent failures.

Ready to cut your energy bills? Ask Anglian Compressors, a Branch of Atlas Copco Compressors, about a professional air audit.

Your Partner in Compressor Room Design

A well-planned compressor room installation can provide substantial measurable payback through energy savings, productivity, and a safer, code-compliant work environment.

Work with an expert to navigate the complexities of planning your air compressor installation and take advantage of the wealth of benefits it provides. Contact the experts at Anglian Compressors, a Branch of Atlas Copco Compressors, today to book a site assessment or download our free compressor room design checklist.