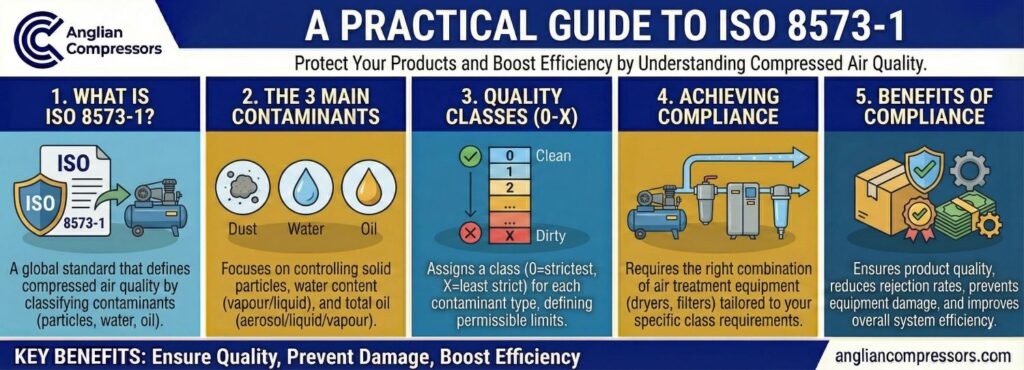

A Practical Guide to ISO 8573-1: Protect Your Products and Boost Efficiency

Compressed air is now regarded as the fourth utility in any modern manufacturing plant, but its quality is often taken for granted. As an experienced Atlas Copco distributor, Anglian Compressors can assist in the UK to help businesses work towards 100% ISO 8573-1 compliance. For any application where process purity is critical, the international standard is considered best practice. Compliance is at the heart of your operation, product quality, and regulatory requirements. This guide details the standards, the consequences of non-compliance, and how to design a system that meets the specific air quality requirements of your application.

Why Your Compressed Air is Not Clean

The core challenge is that any unfiltered, ambient air drawn into a compressor is contaminated. A single cubic metre of air contains millions of particles of dust and pollen, along with water vapour and hydrocarbon vapours from industrial and vehicle emissions.

Compression concentrates these contaminants to the point where air that is compressed to 7 bar, has a contaminant concentration eightfold its original. This process transforms atmospheric air into a potential threat to your equipment and products.

The High Cost of Contamination and Risks of Non-Compliance

Ignoring compressed air quality leads to significant financial and operational consequences. The risks are systemic and affect every part of your facility.

- Product Spoilage & Rejection: Oil aerosols create surface defects like “fish eyes” on paint applications and, in food/beverage processing, oil, water, and microbes can spoil an entire batch, triggering recalls and catastrophic brand reputation damage.

- Damage & Downtime: Solid particles act like a sandblaster on pneumatic tools, valves, and fittings, causing premature wear and rusting. This corrosion in your pipes and air receivers then creates ever increasing particle contamination as damage introduces more moisture. The result of this degradation is increasing maintenance costs and more frequent unplanned production downtime.

- Operational Inefficiency: Contaminants in your compressed air system clog the filters, causing pressure drops that force your compressor to work harder and use more energy. Poor air quality also decreases the efficiency of your tools and any other processes your compressor powers.

The need for the ISO 8573-1 air quality standard is clear after reviewing these risks, and compliance helps you keep these failures from derailing your business.

ISO 8573-1: The Global Standard for Air Purity

ISO 8573-1: 2010 is a precise, universally accepted, classification system for the main contaminants found in compressed air. Because of this standardisation, users and manufacturers respectively can clearly define the level of air purity required for their applications, and specify the performance of their products.

The Three Pillars of Purity: Particles, Water, and Oil

The 3 classes of air purity have accepted levels of contaminants that fall under three major categories:

- Solid Particles: The maximum number of solid particles per cubic metre by size.

- Water: The maximum content of water allowed, based on the Pressure Dew Point (PDP), the temperature at which a vapour turns into a liquid. The lower the PDP, the drier the air.

- Total Oil: The concentration of total oil, both liquid, aerosol, and vapour, in mg/m3.

How to Read the Purity Classes

Air quality is classified in: ISO 8573-1:2010 according to its individual P:W:O classes – where P = Particle class, W = Water class, and O = Oil class. A good general rule of thumb for all classes is: the lower the number the cleaner the air, with Class 1 being much cleaner than Class 3.

Here is a simplified table showing common purity classes:

Common Purity Classes

| Class | Particles | Water (PDP) | Total Oil |

| 1 | ≤0.1 µm | -70°C | ≤0.01 mg/m³ |

| 2 | ≤1 µm | -40°C | ≤0.1 mg/m³ |

| 3 | ≤5 µm | -20°C | ≤1 mg/m³ |

The Special Case of Class 0

Class 0 is the most stringent air purity classification and is often misunderstood. It does not mean zero contamination. Class 0 is actually a customisable classification defined by the equipment user or supplier as being more stringent than Class 1. A claim of “Class 0” therefore must be accompanied by a specific, measurable purity level, transforming it into a contractual performance guarantee.

Engineering a Compliant System: Your Air Treatment Toolkit

Achieving a specific ISO 8573-1 class requires a carefully designed, multi-stage air treatment system, with each component playing a specific role in removing contaminants.

Compressor Technology: The Foundation of Air Quality

The choice of compressor is the first critical step. While oil-injected compressors can achieve high purity levels with extensive downstream filtration, they carry an inherent risk of oil contamination. For purity critical applications, oil-free compressors are the solution. As a trusted Atlas Copco distributor, we supply TÜV-certified ISO 8573-1 Class 0 compressors that eliminate the risk of oil being introduced by the machine.

Air Dryers Remove Moisture Impurities

The water class you are required to meet dictates the dryer technology you need.

- Refrigerant Dryers are an energy-efficient option for achieving a PDP of +3°C, making your air suitable for Water Classes 4 to 6.

- Desiccant Dryers are essential for applications demanding extremely dry air. They are capable of achieving PDPs as low as -70°C to meet Water Classes 1, 2, and 3.

Filtration, Pipework, and Monitoring

A series of high-efficiency Compressed Air Filters and Air Purity Classes are needed to remove any remaining particles and oil, with coalescing filters removing oil aerosols, and activated carbon filters removing oil vapour for the most critical purity requirements.

Long-term compliance also depends on your distribution network. Atlas Copco’s AIRnet aluminium pipework prevents corrosion and scale build-up, ensuring your compressed air remains pure right to the point of use.

For ultimate control, Atlas Copco’s SMARTLINK technology provides real-time monitoring and performance alerts. Energy efficiency can also be maximised with heat recovery systems which capture waste heat from the compressor, making it available for use elsewhere in your facility.

Industry-Specific Requirements for ISO 8573-1 Compliance

Different sectors have different risks, which is why ISO 8573-1 is not just one-size-fits-all.

- Food & Beverage: A common requirement to comply with standards like BRCGS and HACCP in the food and beverage industry, is Class [2:2:1]. The -40°C PDP (Water Class 2) is critical for inhibiting microbial growth. See our guidance on Food and Beverage Industry Air Quality Standards.

- Pharmaceuticals: Governed by Good Manufacturing Practice (GMP), this sector demands the highest purity, typically requiring specification class [1:1:1], or a user-defined Class 0. Learn more about ISO 8573-1 Class 0 for Pharmaceutical Applications.

- Electronics: To prevent microscopic defects from causing soldering defects or short circuits which damage sensitive components, a specification of Class [1:2:1] or [1:1:1] is often required.

- Automotive Finishing: A flawless paint finish requires air free from oil and water. Oil Class 1 or 0 prevents “fish eyes,” while Water Class 1 or 2 prevents micro-blistering.

Compliance Verification and Legal Duties

Compliance is not a one time event; it is an ongoing activity, requiring maintenance and verification. Filters become saturated through use, drains can clog, and dryer efficiency can suffer.

The Importance of Regular Air Quality Testing

Unless professionally tested, there is no way to validate that your system is performing to its specified purity class every day. Testing frequency is based on risk, i.e. critical applications such as food or pharma may require quarterly testing, while yearly testing is acceptable in general industry. For regulated industries, testing is generally required to be carried out by an independent third party, with their verification acting as the documented proof required by auditors.

UK Legal and Regulatory Obligations

Keeping your air treatment system in good order is your legal responsibility. The Pressure Systems Safety Regulations 2000 (PSSR) and Provision and Use of Work Equipment Regulations 1998 (PUWER) both make you responsible for making sure that your equipment is safe and in good working order. The same service activities required to keep your system ISO 8573-1 compliant are also essential for meeting these legal responsibilities. That’s why, as part of our service plans, Anglian Compressors, a Branch of Atlas Copco Compressors, will ensure your system is not only producing pure air, but is fully compliant with UK regulations such as PSSR.

Ensure your compressed air system meets ISO 8573-1 compliance: Contact Anglian Compressors, a Branch of Atlas Copco Compressors, today for a free assessment and tailored advice on Recommended Air Treatment Equipment for ISO Compliance.