A Guide to On-Site Nitrogen Generation for Laser Cutting

Choosing the right assist gas is critical in laser cutting and other manufacturing processes.

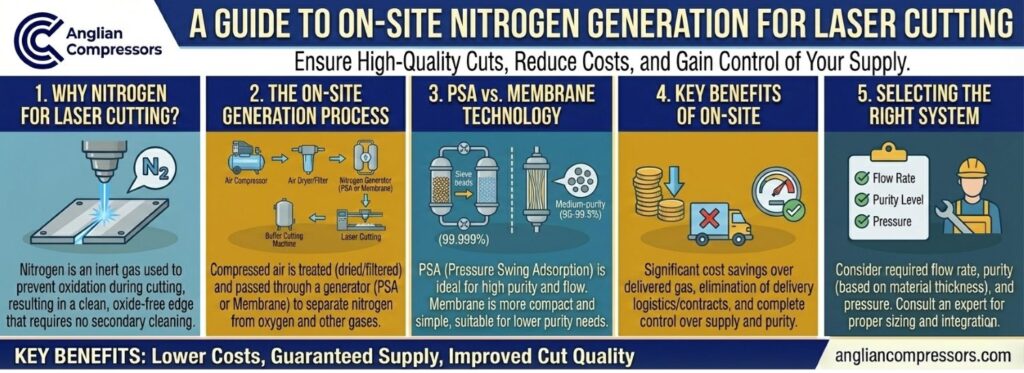

In laser cutting, nitrogen is the industry standard for stainless steel and aluminium cutting. Nitrogen is inert, and when used to assist cutting, it leaves a clean, oxide-free edge with no need for secondary finishing.

Traditionally, manufacturers have sourced nitrogen in the form of pressurised cylinder deliveries or bulk liquid tank deliveries. This model has several drawbacks in terms of operation and finance.

An alternative is to generate nitrogen on-site for laser cutting. On-site nitrogen generation is the use of a dedicated system to separate nitrogen from the surrounding air.

This guide details the technology and the case for on-site nitrogen generation in UK laser cutting facilities.

Key Benefits of On-Site Nitrogen Generation

- Eliminates up to 90% of nitrogen costs in many cases

- Gives complete control of nitrogen supply and eliminates dependence on third-party delivery

- Delivers a constant supply of high-purity nitrogen to maintain cut quality

- Eliminates the safety risks of high-pressure cylinders and cryogenic liquids

- Lowers a facility’s carbon footprint by ending road transport for gas supply

Challenges of Traditional Nitrogen Supply

Leasing gas from an outside vendor also involves some ongoing inefficiency and risks. These include: (1) ongoing rental charges for cylinders or tanks, (2) variable delivery surcharges and (3) risk of production downtime if a delivery is missed. In addition, both common supply methods involve wasted gas, from either residual pressure in returned cylinders or “boil-off” evaporation from liquid tanks.

| Supply Method | Key Drawbacks | Purity Control | Reliability |

| Bulk Liquid Tank | High cost, “boil-off” waste (5-10%), long-term supplier contracts, delivery-dependent. | Fixed high purity (often over-specified). | Vulnerable to supplier delays and stock-outs. |

| Gas Cylinders | High cost per unit, manual handling safety risks, wasted residual gas (10%+). | Fixed purity per cylinder. | Requires constant inventory management. |

| On-Site PSA Generation | Initial capital investment. | Fully adjustable to match job requirements, optimising cost. | 24/7 on-demand supply. |

The On-Site Nitrogen Generation Solution

Producing nitrogen on-site replaces supplier dependence with full control over the gas supply. This model offers a number of advantages that are both operational and financial:

- Cost Reduction: On-site systems generate nitrogen at a much lower cost per cubic metre, which helps eliminate rental fees and delivery charges. On top of this, the return on investment is often realised within 6 to 24 months. This means that you’re adding further cost savings.

- Supply Reliability: An on-site system produces nitrogen on demand. This helps to ensure you a continuous supply with less volatility – allowing for predictable production scheduling and maximising the uptime of laser cutting equipment.

- Purity Control: Operators can set the exact nitrogen purity needed for each material or job directly on-site, which avoids producing gas at unnecessarily high purity levels and reduces energy costs.

- Improved Safety: Eliminates cylinder handling and cryogenic risks, creating a safer workplace.

- Sustainability benefits: Because the system eliminates frequent truck deliveries, transport-related emissions are lowered – making it easier to meet environmental management standards like ISO 14001.

How the Technology Works

An on-site nitrogen generation for a laser cutting system is an integrated package of equipment.

The Integrated System

A complete system, often supplied on a “plug-and-play” skid, contains four stages:

- Air Compressor: The rotary screw compressor compresses the ambient air.

- Air Treatment: Filters and dryers clean the air to the required quality (e.g. ISO 8573-1 Class 0), protecting the generator.

- Nitrogen Generator: The nitrogen generator separates the nitrogen from the treated compressed air.

- Booster & Storage: A booster increases the nitrogen pressure for storage in receiver vessels, meeting the high-pressure demands of the laser.

PSA vs. Membrane Technology

The technology of choice for high-purity laser cutting is Pressure Swing Adsorption (PSA). PSA systems such as the Atlas Copco NGP+ series employ a Carbon Molecular Sieve to separate nitrogen to purities of up to 99.999%.

This high purity of nitrogen is required to ensure there is no oxidation when cutting sensitive materials.

Learn more about the process here: How Does a Nitrogen Generator Work?

VSD Compressors for Efficiency

Nitrogen generators have a variable demand for compressed air.

A VSD compressor (Atlas Copco GA VSD+), for example, changes the speed of the motor to suit demand. This can save a large amount of energy over a fixed-speed equivalent.

System Monitoring and Connectivity

Today’s generators can be remotely monitored using systems such as Atlas Copco’s SMARTLINK. This type of system comes with a whole host of benefits, such as allowing for real-time information about system performance.

Predictive maintenance is possible, and the system can be integrated with the facility’s Industry 4.0 or SCADA system.

System Specification for Laser Cutting

For a nitrogen system to perform efficiently, correct sizing is essential. Flow rate (Nm³/h) and pressure requirements depend on the laser’s power, the material, and its thickness.

- A smaller 2kW fibre laser might consume 20–40 Nm³/h.

- A larger 10kW machine cutting thick plate could require over 100 Nm³/h.

Purity requirements are also application-specific:

- Stainless Steel & Aluminium: Typically require 99.99% to 99.999% purity.

- Mild Steel: Often requires 99.9% to 99.95% purity for a clean edge.

Higher pressures are needed to cut thicker materials. This often requires a booster, a device we explain in our guide What is a Compressed Air Booster?. An expert site audit can determine the optimal configuration and explain How Nitrogen or Oxygen Purity Affect Their Cost.

Case Studies in UK Manufacturing

The results of on-site generation are documented in UK manufacturing facilities using Atlas Copco UK solutions.

- Concept Metals (Manchester): This company installed an Atlas Copco nitrogen skid package to replace an unreliable bulk supply. The system reduced their annual nitrogen expenditure by 75%.

- LaserMaster (Cornwall): By switching to an on-site system, this business reduced its nitrogen cost from 40p per Nm³ to 4p, resulting in estimated annual savings of £30,000.

This transition is similar to that of our Advanced Engineering Case Study, which used an on-site system to support its fabrication services. The need for high purity is also seen in other sectors, as detailed in our guide for Air Compressors for the Electronics Industry.

Selecting a fully engineered solution (compressor, treatment, generator, booster and service) from a single specialist source is the best way to ensure all components are accurately matched for performance and reliability.

To find out how on-site nitrogen generation could be utilised within your own operation, please get in touch with Anglian Compressors, a Branch of Atlas Copco Compressors, to arrange a site audit.