If you rely on compressed air installations to power your industrial business, you must ensure that a suitable written scheme of examination for air compressors (WSE) is in place to remain compliant with the law. Fortunately, the benefits of getting a competent person to create and approve your WSE extend far beyond just legal requirements.

A qualified inspector can evaluate the condition and system safety of your air compressors and crucial components, which minimises the risk of workplace accidents and supports your overall health and safety goals, while helping you catch and repair small problems early. Ensuring your compressors are in full working order can boost energy efficiency and workplace productivity.

At Anglian Compressors, a branch of Atlas Copco, we have been a premier distributor since 1977 — giving you confidence that our qualified WSE inspectors are fully up to date with the latest innovations and standards. Prioritising your business needs, we can conduct a WSE at a time that works with your schedule to minimise downtime.

Call us today, and we will tell you more during a no-obligation consultation.

What Is a Written Scheme of Examination?

All businesses that use pressure systems where the product of the safe working pressure (in bar) and the internal capacity in litres (L) of any pressure vessel is greater than 250 bar-litres must have a written scheme of examination (WSE) in place before the system is operated. This is a statutory requirement under the Pressure Systems Safety Regulations 2000 (PSSR 2000). These regulations, enforced by the Health and Safety Executive (HSE), are designed to ensure all UK businesses operate in line with minimum safety standards to prevent the serious danger of stored energy.

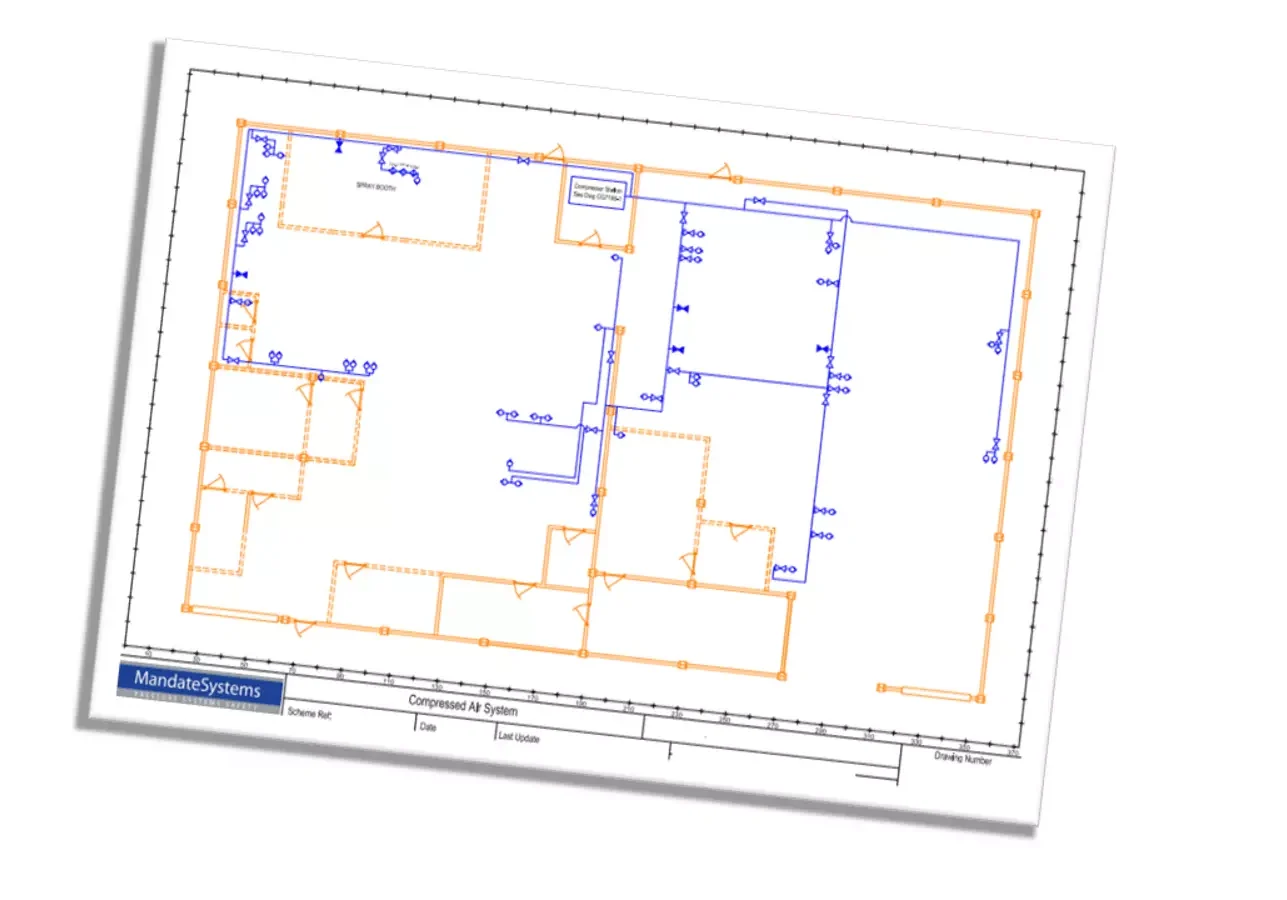

Compiled by a 'Competent Person', your WSE contains the details of your compressed air system, its pressure vessels (like an air receiver), pipework, and all associated protective safety devices and components. It also includes a schedule for future safety examinations so that you can remain compliant.

Obtaining a WSE is not just a legal requirement – it is an essential step towards maximising workplace safety and the lifespan of your equipment. Thanks to our routine WSE services, staying compliant could not be more straightforward. And we can also potentially shave a significant sum off your running costs while helping you stay on the right side of the law.

Do Compressors Require Statutory Inspection?

Yes, under the PSSR 2000, most industrial air compressors require a statutory inspection. The regulations apply to the owners and users of installed systems containing a relevant fluid (such as compressed air) under pressure. If your system incorporates an air receiver or pressure vessel that falls above the 250 bar-litre threshold, a Written Scheme of Examination is mandatory.

This statutory inspection is distinct from regular maintenance. While maintenance looks after the mechanical function of the air compressor, the statutory inspection and WSE focus specifically on the pressure risks and the integrity of the system to prevent catastrophic failure. Ignoring these requirements can invalidate your insurance and lead to prosecution.

What a WSE Includes

The WSE is a formal legal report containing a record of your compressed air system and critical components like safety valves and pressure gauges.

Key details include:

- Details so you know the safe operating limits for pressure and temperature

- A rigorous record of all plant or equipment and critical components, including the air receiver

- Details of your inspection schedules and the types of examinations required, including any preparatory work needed (e.g. whether the system is drained or live)

- Identification of all safety devices fitted to the system

Your WSE must be drawn up or certified by a competent person with extensive experience. This isn't just a case of simple maintenance; the HSE's guidance often requires a 'Competent Person' to have a high level of engineering expertise and impartiality, often to the level of an Incorporated or Chartered Engineer. You also need an inspector who can minimise business downtime without cutting corners. Find out how we prioritise efficiency by giving us a call.

The Benefits of a WSE

There are many tangible benefits to getting a WSE from a qualified professional, such as:

Legal Compliance

Failing to comply with your WSE requirements can result in hefty fines and penalties. This includes ensuring the pressure system is actually examined in accordance with the written scheme.

Enhanced Workplace Safety and Risk Assessment

Ensuring your compressors are in full working order minimises the risk of workplace accidents. A regular safety inspection ensures your systems are safe and fit for purpose, functioning as a vital part of your overall risk assessment strategy.

Extended Equipment Lifespan

Staying on top of maintenance and catching small problems early enables you to repair minor issues and keep your equipment running longer.

Reduced Costs

Catching and repairing minor problems before they spiral out of control can reduce your upkeep fees.

Increased Energy Efficiency

You can also optimise your energy usage by staying on top of maintenance.

Improved Operational Efficiency

By reducing the risk of system failures and downtime, you can ensure your business runs smoothly.

Our Range of WSE Services

Our fully qualified engineers can provide all necessary services required by the pressure systems regulations. We can handle all your WSE needs, from creating your initial report and defining your inspection schedule to performing routine evaluations on time without you having to lift a finger.

Following an initial assessment, which we can do when our qualified inspectors to come to site to discuss the process, we will tailor an inspection scheme based on your unique business requirements and the configuration of your air compressor and pressure systems. We will then inspect and test your equipment using the latest technologies, including ultrasound testing and safety device checks.

When it is time for another inspection, to help you remain compliant, we can offer reminders so you never fall behind. We will always conduct inspections at a time that works best with your busy schedule to help minimise business downtime and keep things running smoothly.

Book Your WSE Inspection Today

Enhance workplace safety, extend the lifespan of your compressed air installations, and ensure full compliance by choosing Anglian Compressors, a branch of Atlas Copco, for your WSE inspection.

With nearly five decades of experience under our belts, we have retained our reputation for excellence by always remaining on top of the latest developments and offering unparalleled customer service. We also aim to set the bar high when it comes to value and reliability, so call us to book your WSE inspection today.

Frequently Asked Questions

This is a critical distinction. A WSE is a statutory safety inspection plan focused on preventing danger and ensuring legal compliance. It is an 'examination' focused on safety-critical items like the air receiver, safety valves, and pressure gauges. Maintenance, on the other hand, involves servicing parts like filters and oil to ensure operational efficiency and reliability. A maintenance service report cannot substitute for a formal WSE examination report.