The third utility, after electricity, gas, and water, is compressed air. If you get this choice wrong, your energy efficiency is the least of your worries. An incorrectly specified air compressor can impact productivity and operating expenses, while also putting your operation at risk of non-compliance. For UK manufacturers who often need to strike a careful balance between automation and air purity, the right compressed air solution is a business-critical choice.

Peterborough facilities and those across the East of England have a particularly challenging task. The area straddles the traditional base of advanced manufacturing in the East Midlands and the high-value electronics and life sciences cluster in Cambridge. It’s a dual market in which some facilities require rugged, cost-effective reliability, while others require the ultimate purity of Class 0 oil-free air for extremely sensitive processes. A winning compressed air strategy satisfies both demands: absolute performance and zero compromise.

In this guide, we explain the considerations that are key to choosing an industrial air compressor system that will drive efficiency and support your long-term growth.

Select the Right Compressor for Your Application

The foundation of an efficient system is a compressor technology matched to your specific application and demand profile.

Rotary Screw Compressors: The Industry Standard for 24/7 Production

Designed for continuous operation, rotary screw compressors are the standard for most manufacturing facilities.

- Fixed-Speed Models: Ideal for operations with a consistent, stable air demand.

- Variable Speed Drive (VSD) Models: For facilities with fluctuating air demand, Variable Speed Drive (VSD) compressors are the superior choice. By automatically adjusting motor speed to match real-time air consumption, they can reduce electricity use by up to 50%.

Oil-Free Compressors: Guaranteed Purity for Sensitive Applications

In the food, pharmaceutical, and electronics industries, the risk of oil contamination causing product spoilage and recall is a significant concern. Oil-free compressors offer 100% risk mitigation. Atlas Copco’s compressors are the world’s first to be certified to the highest industry standard ISO 8573-1 Class 0 for air purity, which is critical for customers seeking Air Compressors for the Electronics Industry.

Piston Compressors: A Robust Choice for Intermittent Use

Small workshops or applications with an intermittent need for air supply can benefit from a piston compressor. Piston compressors have a lower initial purchase cost.

Ensure Air Purity and System-Wide Integrity

Generating compressed air is only half the battle. Untreated air contains water, oil, and particulates that can cause corrosion and contaminate final products.

- Air Treatment: A complete system includes air dryers (refrigerated or desiccant) to remove moisture and multi-stage filtration to capture contaminants.

- System Design: The efficiency of your entire system depends on its layout. A properly engineered network of Compressed Air Piping Systems minimises pressure drop, ensuring consistent power at the point of use.

Cut Energy Costs and Reduce Your TCO

Compressed air isn’t just a machine, it’s your facility’s fourth utility. Like electricity or water, it needs to be carefully specified, monitored, and maintained to maximise performance and ROI. Energy accounts for up to 80% of an air compressor's total lifecycle cost. This makes efficiency the single most significant opportunity for reducing operational expenditure. Reducing system pressure by just one bar can cut energy costs by 7%.

- Pinpoint Waste with Energy Audits & Leak Detection: A typical unmanaged system loses 20-30% of its compressed air through leaks. A single 3mm leak at 7 bar can cost over £2,000 annually in wasted electricity. Using advanced ultrasonic leak detection equipment, our engineers can pinpoint and quantify every leak.

- Reclaim Value with Heat Recovery: As much as 94% of the energy consumed by an air compressor is eventually exhausted as heat. A heat recovery system can reclaim waste heat and use it to heat water or space, turning a primary operating cost into a positive energy credit.

There are many ways to make your Air Compressor more efficient, from optimising pressure settings to implementing a proactive maintenance schedule.

Tailored Solutions for Your Industry

The compressed air needs of different industries are as varied as their applications.

- Advanced Manufacturing & Automotive: Pressure stability and absolute dependability are mission-critical for advanced manufacturers who use compressed air to power assembly tools, run robotic welders, and provide perfect paint finishes.

- Food, Beverage & Electronics: Purity is critical. In addition to Class 0 air, many food/beverage and electronic assembly applications call for an inert atmosphere. On-site nitrogen generation with Atlas Copco NGP⁺ or NGM⁺ systems provides a highly cost-effective alternative to bottled gas for these and other applications, such as food packaging and electronic soldering.

Maximise Uptime with a Lifecycle Partner

Downtime in manufacturing can cost thousands per hour. A proactive partnership ensures your compressed air system remains a reliable asset.

- Proactive Maintenance: A scheduled service plan is essential for operational continuity. Our Air Compressor Maintenance Guide outlines the key activities that prevent breakdowns.

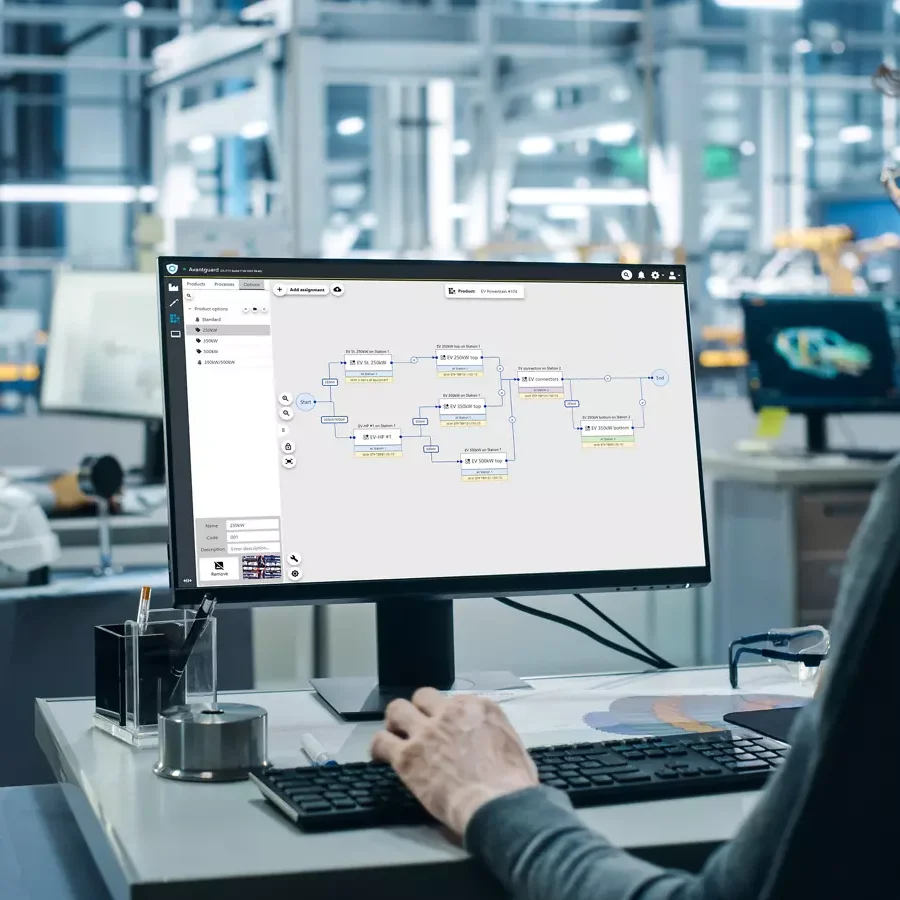

- Remote Monitoring: Systems such as Atlas Copco SMARTLINK enable 24/7 remote monitoring of your system, providing real-time performance data and proactive maintenance alerts, which help you address problems before they cause a shutdown.

Navigate PSSR 2000 Compliance with Confidence

It’s important to note that when you run a pressure system, you have a legal duty of care. The Pressure Systems Safety Regulations 2000 (PSSR) require that all relevant systems have a Written Scheme of Examination (WSE) in place. Your system is likely to need a WSE if the product of the pressure in bar and vessel volume in litres exceeds 250 bar litres (e.g., an 11 bar, 50-litre receiver will have a product of 550 bar litres, so a WSE is required). This can be complicated to manage, so as your expert partner, Anglian Compressors, a branch of Atlas Copco, can take care of the entire process for you.

The Atlas Copco & Anglian Advantage

We have been the exclusive distributor for Atlas Copco compressors since 1977 and can offer you access to leading-edge, world-class compressor technology. Competitors like Kaeser and CompAir are undoubtedly providing reliable systems. Still, when you consider the scope of Atlas Copco’s world-class product portfolio and unrivalled UK service and support network, it’s easy to see why they offer the best solution to help you take more intelligent control of your business and take advantage of lower lifecycle costs and an entirely integrated approach with Industry 4.0 connectivity and platforms.

By choosing Anglian Compressors, a branch of Atlas Copco, as your authorised dealer, you benefit from local knowledge and next-day support you won’t find with national providers.

Ready to Optimise Your Compressed Air System?

For 50 years, we have been working with manufacturers in Peterborough, Leicester, Milton Keynes, and Cambridge. We know that running your traditional production facilities while building next-generation, clean manufacturing sites can pose challenges when it comes to servicing them both. Speak to the Anglian Compressors team, a branch of Atlas Copco, today to book a complete system audit and receive expert advice.