What Size Air Compressor Do I need?

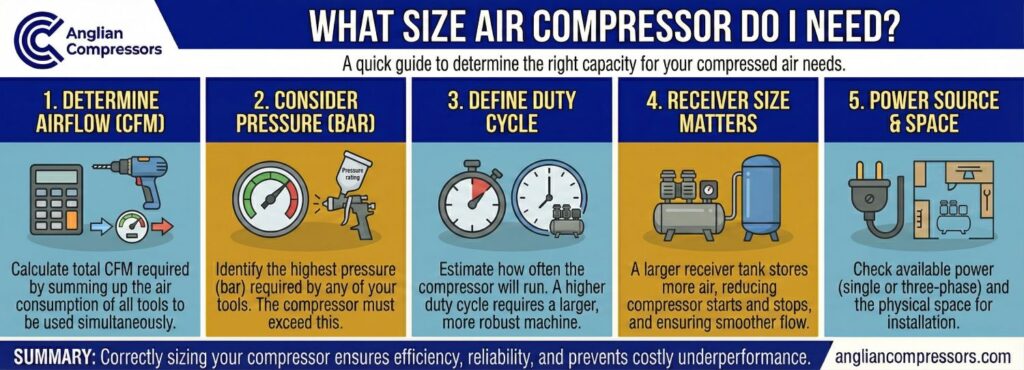

Choosing the right air compressor size is a critical decision that directly impacts operational efficiency, energy consumption, and overall system performance. An incorrectly specified system can lead to reduced productivity and increased operating costs. Getting your pressure right is critical to ensuring all your air-powered tools are functioning effectively.

If you don’t have enough pressure, your tools may not work efficiently, if at all. If there’s too much pressure, you are at best wasting money on unnecessary energy consumption, and at worst risking damaged tools, materials, and even injury.

Understanding the Key Air Compressor Sizing Metrics

The first step to choosing the right air compressor is understanding the measurements they use. You’ll encounter terms like PSI (pounds per square inch), CFM (cubic feet per minute), and Duty Cycle.

These measure different things. Let’s break them down:

- Pressure (PSI): PSI is a measure of pressure, essentially the force a pneumatic tool delivers to a square inch. Most air tools require around 90 PSI to operate correctly.

- Flow Rate (CFM): CFM or air flow, measures the volume of air a compressor can deliver in a minute. The amount of air is crucial because a higher CFM rating means the compressor can power more demanding tools or multiple tools at once. This volume of air produced is one of the most important factors.

- Duty Cycle: The duty cycle refers to how long a compressor can run before it needs to cool down. For intermittent use, a lower duty cycle is fine. For constant, heavy-duty use, you need a compressor with a 100% duty cycle, like a rotary screw compressor.

A simplistic analogy is a hosepipe: the tap represents the compressor, controlling air flow (volume of air). Adding a nozzle or squeezing the hose end increases water pressure, much like how compressed air tools adjust output.

Understanding how your tools use compressed air is critical to judging the air volume you need. But that is just one of the factors you must consider when buying an air compressor.

Factors That Impact Air Compressor Selection

The tools you use

Different tools require different pressures and volumes. Part of this is down to function, for example, the materials they are used on, but also how they work. A pneumatic nail-gun, for example, may seem like it has a relatively low pressure, but that’s because the pressure is focused on a small nail in short bursts of air.

The compressed air system you are using

There will always be some pressure loss in any compressed air system, caused by air hose leaks, bends in the system, or simply the distance from the compressor to the tool. And if your compressor’s CFM rating isn’t high enough to compensate, your tools won’t work effectively. This can affect the compressed air quality and overall performance.

The number of tools

If you’re running multiple tools, you’ll need an air compressor that can generate the air volume AND pressure to meet their collective demand. Your air compressor must be able to handle the combined CFM requirements of all tools operating simultaneously.

Ambient conditions

Even air compressors can be affected by the weather; factors like temperature and moisture will affect the efficiency of tools and your compressor. In the temperate UK, it isn’t usually a problem, but you might need to consider the impact of working in very hot or very cold conditions.

How to Calculate Your Air Volume Requirements

To estimate your needs, start by identifying the maximum air requirement, whether from a single tool or multiple tools operating together.

- List all the air tools you will use.

- Find the CFM requirement for each tool (usually found in the manufacturer’s specifications).

- Add up the CFM of all tools that will be running at the same time. This is your total air demand.

- Apply a safety buffer. It’s wise to add about 25-30% to your calculated total CFM. This accounts for potential air leaks, tool wear, and future expansion. For a rough estimate, you can multiply your total required CFM by 1.5.

This calculation ensures the compressor can deliver enough free air for all your applications without a drop in performance.

Air Tool Volume Needs (CFM)

Tools often require around 90 psi to operate effectively, and that can make things easier for you, since you then have to calculate your air volume needs to produce that for the tools you plan on using.

You should always check the manufacturer’s instructions, but here’s what that means for some common tools and tasks.

Most tools operate efficiently at around 90 PSI (6.2 bar). Below are typical volume requirements for various tools:

Angle Grinding

A common tool for cutting, grinding, and buffing in metalwork, a typical angle grinder will require 5 to 10 CFM.

Tacking

Frequently used in construction, the tool, by its nature, is used intermittently when it drives it’s headless nails into wood. As such, it uses a much lower pressure, requiring just 0.3 CFM.

Joist Nailing

The nail gun offers both speed and accuracy when building frames or simply joining wood. Like tacking, because it uses concentrated pressure, it only requires a relatively low 2 CFM from your air compressor.

Chiselling

A heavy-duty tool, a pneumatic chisel can be used on stone and even metal, making it a useful tool in construction and renovation. Its power needs a higher air volume, though, usually between 5 and 10 CFM.

Cutting

Another heavy-duty use. The cut-off tool can slice through sheets of metal, making it popular for car maintenance, as well as construction and industrial settings. Like the air chisel, it typically requires volumes between 5 and 10 CFM.

Drilling

Pneumatic drills out-power their electrical equivalents, making light work of drilling into metal, brick, and even rock. They will require between 3 and 5 CFM from your compressor.

Orbital Sanding

Air compressors can make sanding a joy, removing all the effort required to get a smooth result. Their continuous use means they tend to need higher pressures and air volumes, often around 10 CFM.

Lubricating

Using compressed air for a focused application of lubricant on anything from hinges to engines makes the process faster, more efficient, and much cleaner. A relatively simple tool, it usually needs around 5 CFM.

Painting

Offering a consistent finish that could never be matched by hand, air brushes are a common fixture in car manufacture and repair. The variety of painting jobs compressed air can do is reflected in the range of pressures you might need. Depending on the spray gun and the job, especially for spray painting, you might need to generate anything from 5 to 15 CFM or more.

Metal Nibbling

Used for precision cutting in sheet metal, trimming metal surfaces, or just to remove sharp edges, nibblers require 5 CFM.

Ratcheting (and Unscrewing)

Compressed air’s power makes it ideal for both tightening those things that need to stay in place or using an impact wrench to loosen those bolts that are stuck fast. The size and situation will dictate the air volume requirement, with anything from 2.5 to 10 CFM.

Sawing

Compressed air can power saws that never tire, whether it’s from the sheer volume of work (modern pneumatic saws make as many as 9,000 strokes a minute) or the strength of the material being cut — all on just 5 CFM.

Shearing

The air shear can cut through seemingly anything; a standard model will not be troubled by steel up to 20-gauge. But it will need a good air compressor to do it, generating between 5 and 15 CFM.

Selecting the Right Compressor Technology

The type of air compressor you choose is as important as its size. Different compressors are designed for different workloads.

- Piston Compressors: These are a common choice for intermittent use, such as in small workshops or for DIY projects. They are not typically suited for continuous operation.

- Rotary Screw Compressors: For continuous, heavy-duty industrial use, a rotary screw compressor is the industry standard. They are built for a 100% duty cycle, providing a constant and reliable flow of compressed air.

- Oil-Free Compressors: In applications where air quality is paramount, such as in food processing, pharmaceuticals, or electronics, an oil-free compressor is essential to prevent contamination.

Risks of Improper Sizing

Choosing a compressor that is too large or too small leads to inefficiencies and potential damage.

- Undersizing: An undersized compressor will struggle to meet air demand, causing tools to underperform and the compressor to run constantly, leading to overheating and premature wear.

- Oversizing: An oversized compressor will “short cycle” – turning on and off too frequently. This wastes significant energy, increases operational costs, and causes unnecessary wear on components.

The Importance of Tank Size

The air receiver, or tank size, is another key factor. A larger tank stores more compressed air, which can buffer peak demand and reduce how often the compressor needs to cycle. This improves efficiency and extends the compressor’s life.

Optimising Compressor Performance

Just like any other tools or equipment, proper maintenance is essential. This is especially important for tools used with portable compressors, which have an added risk of damage during transit.

Taking proper care of your compressor and tools will help to ensure optimal performance. You should make a habit of performing a regular visual check on tools and monitoring performance. And this should be supplemented with a regular service of your air compressor and compressed air system to help maximise its effectiveness and lifespan.

Atlas Copco compressors, known for robust design and energy efficiency, offer a range tailored for various applications. Anglian Compressors, a Branch of Atlas Copco Compressors, provides maintenance plans to help maximise the lifespan and performance of your system.

Using the right air compressor will always pay dividends. At Anglian Compressors, for example, a Branch of Atlas Copco Compressors, a world-leading manufacturer of air compressors, for their range that includes compressors for any purpose imaginable. But whatever compressor you have, we can offer routine servicing to help you get the most out of it.

Getting the Right Compressor for Your Needs

Trying to choose the right air pressure might seem overwhelming at first, but it’s a skill you will quickly develop as you understand how your compressor and tools work together. If you have any doubt, it’s always better to start with a lower pressure because, although you might find your tools are underpowered, you avoid the risk of damage or injury.

But even better advice is to speak to the experts. The most accurate way to determine the best compressor size for your needs is through a professional air audit, which provides data-driven insights into your exact usage. We can offer consultations to help you understand your system and get the most out of it, design and install entirely new systems, or simply ensure that everything you have is in the best working order possible. We have fully inclusive service plans that can cover every need and eventuality, and clients who have enjoyed decades of consistent, dependable fluid power from their compressors as a result.