What is Compressed Air?

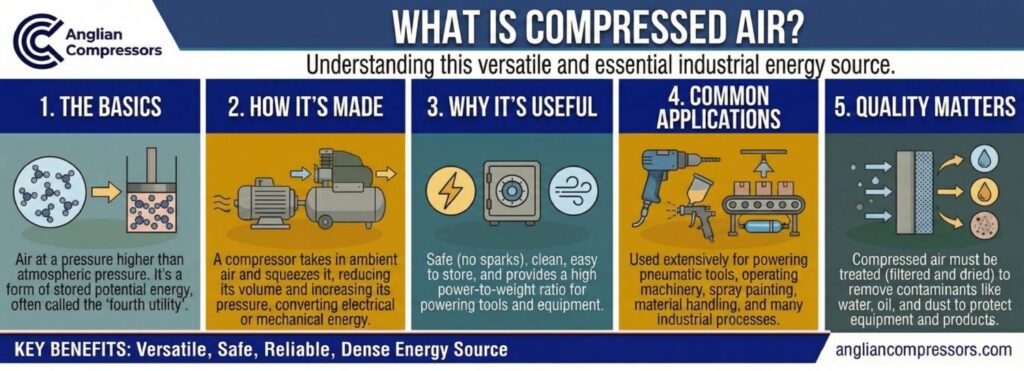

Many industries use compressed air, so much so that it is often referred to as the fourth utility.

Air-powered systems utilise compressed air, such as factory conveyor belts and pneumatic tools. They depend on compressed air for operation and are ineffective without it. Compressed air acts as stored energy in a different form. This makes it a popular energy source for a variety of applications.

Once air is compressed using local ambient air sources, it is immediately usable and can be stored or transported. Air tanks, also known as air receivers, store compressed air on-site for later use. Compressed air is transportable in pressurised canisters and distributable between work sites.

Compressed air can be produced on-site or by a third-party supplier. Producing compressed air on-site offers considerable long-term cost savings, plus pressure levels and other factors are more configurable.

Definition of Compressed Air

Air compressors work through the intake of atmospheric air. Different mechanical methods are used to compress the air into a smaller volume. When air is forced to occupy a smaller space, this creates air compression above normal atmospheric pressure levels. This process increases the air pressure and stores potential energy that can be used to power tools and equipment.

Typically, atmospheric air comprises 21% oxygen, 78% nitrogen, and 1% from other gases. Therefore, while we refer to ‘breathing oxygen’, ambient air only partly consists of oxygen. The air is made up of molecules that are in constant motion.

As stored potential energy, pressurised air can be fed through a network of air ducts or directly into air-fed machinery, delivering compressed air exactly where it is needed.

How is Compressed Air Generated?

Compressors generate compressed air by increasing the air’s pressure and reducing its volume. This process involves taking in non-pressurised air, filtering it, and then channelling it into an internal pressurisation chamber. The air is then mechanically reduced in volume. Air compressors convert electrical or mechanical power into potential energy stored in pressurised air.

When forcing air to occupy a smaller area, it becomes pressurised. All compressors achieve this objective in different ways. Below, we run through some of the different types of air compressors available.

There are two main types of air compressors: positive displacement and dynamic. Positive displacement compressors use a variety of methods to trap and compress air, while dynamic compressors use a rotating impeller to accelerate the air and increase its pressure.

Reciprocating Compressors – These compressors use pistons, moved by a rotating crankshaft, to create a reciprocating system to compress air. They are reliable but tend to create more wear and tear over time.

Rotary Screw Compressors – These compress air by rotating two large screw-shaped parts inside the compression chamber. These create less wear and tear compared to reciprocating compressors. Industrial operators often use rotary screw compressors. They are ideal for continuous use in demanding industrial applications.

Centrifugal Compressors – To generate pressurised air, a spinning impeller moves rapidly and continues accelerating. These are most often found in huge industrial operations rather than smaller ones.

Scroll Compressors – These compressors use two spiral-shaped scrolls to compress air. They are known for their quiet operation and are often used in medical and dental applications where low noise is important.

To learn more about the types of compressors available, please get in touch with Anglian Compressors, a Branch of Atlas Copco Compressors. Our team of experts has extensive application knowledge and can help you choose the right compressor for your application and needs.

Applications of Compressed Air

There are numerous applications for compressed air. Compressed air is used in a wide range of industries and applications, from manufacturing and construction to healthcare and food and beverage.

Some applications are industrial, while others are commercial or domestic. Some have more specific applications for small businesses or personal projects.

Industrial Uses

Compressors used in an industrial setting have a wide range of applications.

Large pneumatic air tools require substantial volumes of highly compressed air. Grinders, sanders, drills, and other workhorse tools are good examples.

Automation is a growing segment within the manufacturing sector. Automated valves are activated using pressurised air instead of relying on human activation. Pneumatic cylinders are also actuated similarly.

Factories make use of industrial-strength air blowers. These provide essential cleaning operations to clean pipes safely and other difficult-to-access areas. In the food and beverage industry, compressed air is used for everything from mixing ingredients to packaging products.

Commercial Uses

Compressed air is part of HVAC control systems in commercial buildings, office parks, and elsewhere. The compressed air plays an important role in controlling valve settings, reducing the human oversight required for the typical HVAC system.

The healthcare field and dental clinics depend on pressurised air, too. Air-powered drills are used during dental operations, and sterilisation tools are essential in the medical field.

Pressurised air helps inflate low-pressure tyres at the petrol station and powers pneumatic air tools in the vehicle workshop. These tasks require access to large volumes of compressed air; otherwise, their customers get impatient and take their business elsewhere.

Everyday Applications

At home, small air pumps are used to inflate sports equipment, increase bike tyre pressure, add extra air to motorcycle/van/car tyres, and more.

Airbrush work and spray painting use specialised spray equipment connected to a steady supply of pressurised air.

Compressed air is also used for general cleaning tasks. During IT repair, canisters of sanitised pressurised air are used to clear away dust from inside PCs, laptops, servers, and other sensitive equipment. Also, dust is quickly removed using portable duct vacuums.

The Benefits of Using Compressed Air

There are various benefits of using compressed air. Below are a few of them.

Compressed air is an efficient energy medium with minimal environmental impact.

While air systems consume a good amount of electricity, the heat produced through the compression process can be harnessed to provide building heating and hot water to bathrooms. This reduces electrical bills for these related expenditures. This process, known as heat recovery, can significantly reduce the overall cost of compressed air.

The electrical power is safely used. Even in explosive or hazardous environments, running air compressors is safer because there is minimal risk of producing electrical sparks.

Generated compressed air is not lost. Even when downstream equipment does not require all the air generated, it is easily stored on site inside air tanks without significant loss of energy or air quality. Alternatively, safely transporting it off site is possible, too.

Compared to other mechanical energy transmission forms, compressed air does not weigh you down with maintenance requirements.

Safety Considerations and Health and Safety

Like all industrial or commercial equipment, air systems have safety considerations. While these should not deter you from using them, prioritising safety is essential.

Understand the Risks

Operating loud, sizable equipment, including those with moving parts or air pressurisation systems, introduces the potential for injury or worse.

During operations, some possible risks include ruptured hoses flailing around and impacting someone, an air injection injury, or potential flying debris from a part coming loose.

Also, compressors are louder than some other machinery. Long-term exposure without ear-worn protection can cause hearing damage at higher decibel levels.

Rarely, there are situations where compressed air enters the human body. This can cause air embolisms in the stomach or lung areas. Such injuries are often severe and can be fatal. These pockets of air can block blood flow and cause serious health problems.

An abundance of caution is necessary around air systems to ensure everyone’s safety.

Best Practices for Safe Operation

Following air system best practices is necessary to operate safely.

Regularly inspect air compressors, air dryers, connected hoses, ducting, and other aspects of the whole air system. Complete preventative maintenance of air compressors and hoses to avoid a part failure or a fitting/hose working loose. Inspecting the compressor and checking the system pressure regularly is a key part of maintaining your compressed air system.

All operators must receive proper training. Focus training on operating the system, proper handling, known hazards and risk factors, and what to do in an emergency. Run safety drills to avoid the training getting stale or forgotten.

Do not allow any unnecessary access to the compressor area or compressor room. All staff accessing these areas must wear protective equipment, including ear defenders and eye protection.

In the UK, the Pressure Systems Safety Regulations 2000 (PSSR 2000) require a written scheme of examination and regular inspection of most compressed air systems.

Need tips on how to make your compressor room safer? Ask our qualified personnel at Anglian Compressors, a Branch of Atlas Copco Compressors, for professional advice.

Environmental and Economic Impact

Compressed air generation is heavily energy-intensive. Depending on the industry, approximately 10 per cent of all industrial-based electricity is consumed in compressed air production.

Improving Energy Efficiency

Air compressors are becoming more energy efficient. Atlas Copco produces Variable Speed Drive (VSD) compressors, which adjust motor speed to match air demand. These produce compressed air at the precise flow rate and compression level required.

Heat recovery systems harness waste heat to produce hot water year round and heating during the colder months. This reduces related energy expenditures in these areas.

Leaking air systems throw money out the window. Compressors must produce extra compressed air to compensate, increasing operating expenses. Air leak audits are worth considering because they can find and highlight current air leaks requiring fixes.

Another area is air quality management. It is often overlooked but can be beneficial. Drying air saves downstream air tools from subsequent damage. Air filtering protects your air system investment in the long term, and filters should be changed regularly.

Economic Considerations

Choosing an air compressor with lower operating costs and better environmental ratings is a win-win. Admittedly, it comes with the initial investment cost, but money is saved by operating it more efficiently over its lifespan.

When replacing an older compressor, the savings become readily apparent once the replacement compressor has been operating for a few weeks.

Regular maintenance provides significant cost savings. It helps operations run more efficiently and prevents wear caused by inadequate maintenance schedules. New compressor owners experience fewer unexpected breakdowns.

Air Quality and Contamination

The quality of compressed air is crucial. Atmospheric air contains contaminants like dust, water vapour, and oil, which get concentrated during compression. Poor air quality can damage equipment and contaminate products.

Main Contaminants

- Solid Particles: Dust, dirt, and rust particles can wear down tools and equipment.

- Water: Moisture in the air can condense in the compressed air system, leading to corrosion and freezing.

- Oil: Oil from the compressor can contaminate the compressed air, which is a major concern in industries like food and beverage and pharmaceuticals.

Air Purity Standards

The international standard for compressed air quality is ISO 8573-1:2010. It classifies air purity based on the maximum allowable levels of solid particles, water, and oil. The highest purity class is Class 0, which guarantees oil-free air.

Conclusion

Compressed air is essential in today’s world. Numerous industries rely on compressed air to operate safely, efficiently, and at a lower cost.

Producing compressed air on site is less expensive than purchasing air supplies and waiting for deliveries. When deciding to generate compressed air, be sure to understand the benefits and the safety considerations, too. Adopting best practices saves a lot of headaches later.

Please get in touch with our team at Anglian Compressors, a Branch of Atlas Copco Compressors, for a free compressed air consultation today. Would you like to learn more?