What is a Nitrogen Gas Purifier?

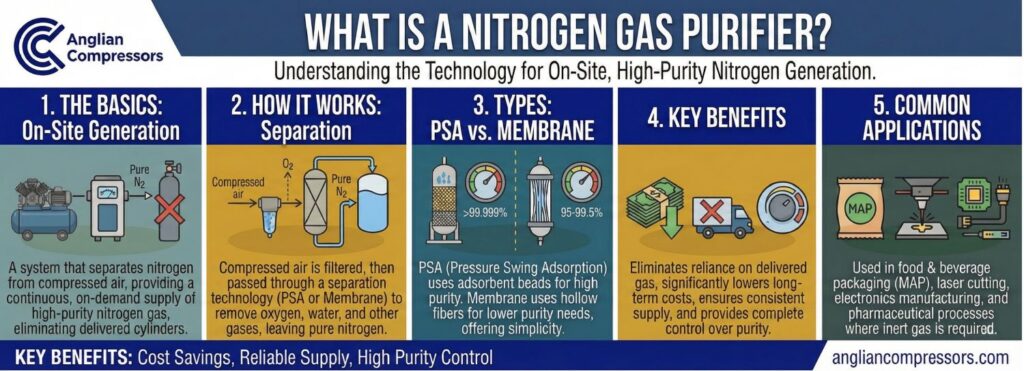

A nitrogen gas purifier improves the purification level in gas supplies. While nitrogen gas supplies may initially have possessed a superior purification level, they can decline due to contaminants introduced unintentionally.

This blog post explains what a nitrogen gas purifier is, its importance for nitrogen users, different types, important considerations, benefits, maintenance, and best practices.

Understanding Nitrogen Gas Purifiers

While Nitrogen (N2) purity typically meets specifications from a supplier or when produced in-house, it does not necessarily remain at that level. Contaminants, such as metal or rust inside pipework or exposure to H2O, measurably alter the nitrogen gas.

Why does this matter? Nitrogen must meet strict purity standards set by individual industries. This applies whether the gas will be deployed for pressure testing, blanketing, electronic soldering, or pharmaceutical manufacturing.

Definition

A nitrogen gas purifier removes impurities from nitrogen gas supplies. When used appropriately, it can help to increase purity to the desired level.

Ultra-high and higher-than-normal purity levels apply to specific industries. Some industries can use nitrogen with a 95% purity level, while others cannot.

Applications and industries such as laser cutting, medicine production, injection moulding, and food processing (fruit storage, wine blanketing, and oil sparging) require 99% or as high as 99.999% purity levels.

Functionality

Purification systems use a purifier module or other approaches to remove contaminants from the gas supply.

Equipment makes use of adsorption and catalytic methodologies to achieve the desired results.

The more common types of contaminants removed are:

- Hydrocarbons

- Helium

- Oxygen

- Moisture

- Trace metals

Gas purification is often performed at room temperature. However, applying heat can enhance performance.

Importance of Nitrogen Gas Purity

Nitrogen gas purity is critical.

Below are some examples of why this is the case.

Industrial Applications

In industrial applications, metal processing and chemical processing plants must avoid oxidation. This occurs when oxygen encounters other elements. Purification systems successfully remove H2O to prevent this.

Food production and packing are another important area. During the packaging process, an inert atmosphere is necessary to prevent contaminants from getting into the food before or as it is being sealed. Nitrogen is an inert gas, making it useful for this activity.

Clean environments, such as electronic manufacturing, require ultra-high purity levels for soldering and related activities.

Laboratory Applications

Pure gas products are needed in a laboratory setting to ensure accurate results. This is especially true for gas chromatography and LC-MS, where impurities can invalidate results.

Other research and lab testing require contaminant-free environments for reliable, consistent outcomes. Otherwise, the results become worthless.

Types of Nitrogen Gas Purifiers

There are several purifiers available. Below, we cover three of the different types.

Ambient Temperature Purifiers

Point-of-use applications often use ambient temperature purifiers over other types. This applies to LC-MS and others.

This type benefits from being more compact. Also, it integrates well with existing systems rather than requiring an overhaul.

The standard litre per minute (SLPM) rating for flow rates goes up to 1,000 slpm, which supports almost all requirements.

Heated Getter Purifiers

Removing certain contaminants, such as moisture or hydrocarbons, proves more challenging. Heated getter purifiers run at high temperatures, allowing them to remove these stubborn elements.

Also, this type is a good choice when needing ultra-high or even extreme gas purity.

Catalyst and Adsorber Systems

The third type is the catalyst and adsorber version. It relies on a dual process – the PS9 series uses this approach – to achieve incredibly high purity levels.

In some situations, the purity level reaches 99.9999%, which applies to the most demanding applications. These systems also support industrial uses where high flow is required (approximately 3,000 Nm³/hr).

Need to know more about the different nitrogen gas purifier products? Get in touch with our nitrogen experts at Anglian Compressors, a Branch of Atlas Copco Compressors, today.

Selecting the Right Nitrogen Gas Purifier

Different selections come to mind when picking the most appropriate nitrogen gas purifier for your needs.

Some considerations and recommendations are below.

Considerations

Flow Rate

The flow rate – how much nitrogen gas can be purified in real time – is highly relevant. It differs markedly between an industrial and a laboratory setting.

In most situations, production cannot be slowed to match low flow rates. Therefore, it is best to choose a solution that supports current and future flow requirements.

Purity Requirements

Purity levels – from 99.9999% ultra-high purity to 95% purity for fire prevention or pressure testing – are also crucial.

Only a purifier meeting achievable purity levels will do.

Specific Contaminants

Different purifiers are better at removing certain types of impurities. Other contaminants may either not be removed or have a lower purity level.

Watch for oxygen, moisture, and hydrocarbons. These often require specific nitrogen gas purifiers to obtain acceptable results.

Environmental Factors

Do not overlook common environmental factors. Ambient temperatures, internal operating temperatures, and pressure levels all affect outcomes.

Compatibility with existing systems affects potential installation, usage, and the potential for high performance.

Recommendations

Talk with our team at Anglian Compressors, a Branch of Atlas Copco Compressors, for guidance.

We can consult with you, consider all relevant factors, and recommend the most appropriate, scalable solution.

Benefits of Using Nitrogen Gas Purifiers

Below are some benefits of using nitrogen gas purifiers in your operations.

Enhanced Product Quality

Stop product contamination at the most sensitive time during the production process. This applies whether packaging food for distribution or being involved in semiconductor manufacturing.

Increased Equipment Lifespan

Lessen potential wear and tear on expensive equipment by removing corrosive elements present in nitrogen gas.

Operational Safety

Increase operational safety levels by removing potential reactive contaminants as standard.

Energy Efficiency

The latest models are more energy efficient while offering high performance.

Purer gas prevents industrial equipment from getting overworked using lower-purity nitrogen supplies.

Cost Savings

Less potential equipment damage improves machinery lifespan, reducing the total cost of ownership.

Manufacturing processes run more efficiently, with reduced breakdowns.

Maintenance and Best Practices

Adhering to regular maintenance schedules and following best practices when using nitrogen gas purifiers achieves better long-term results.

We recommend the following actions:

Regular Monitoring

Monitor the system regularly. The latest models have built-in monitoring, allowing for real-time analysis. Effective maintenance practices improve gas purity levels.

Use a scheduler to receive regular performance check reminders.

Scheduled Replacements

Replace absorption materials and cartridges as needed. Because each item has a different requirement, follow the guidelines from each manufacturer.

As part of the monitoring process, examine current saturation levels. This prevents sudden performance drops and downtime.

Systems Integration

Check your gas supply system to verify the selected model is compatible.

Use prefabricated kits to make installation easier and reduce setup expenses.

Training and Support

Provide training for the team to learn proper operation and maintenance of the nitrogen gas purifying equipment.

Stay current with the equipment manufacturer’s latest technical support and troubleshooting guides.

Conclusion

Nitrogen gas offers high purity levels. However, gas transportation, distribution systems, and atmospheric exposure can contaminate supplies. A nitrogen gas purifier is needed to ensure the highest purity levels.

Selecting the right purifier and maintaining it correctly delivers consistent purity levels, lower running costs, and notable safety improvements.

Talk with our experts at Anglian Compressors, a Branch of Atlas Copco Compressors, to discuss all your gas-purifying needs.