What Is a Dual-Speed Compressor?

As an industrial or manufacturing business in the UK, you might be wondering how you can improve the performance and energy efficiency of your equipment to reduce your running costs and electricity bills. One simple way to achieve this is to use a dual-speed air compressor to reduce the off-load energy consumed, once the upper pressure set point has been reached. However, before deciding whether to choose a dual-speed compressor as opposed to a single-speed or variable-speed alternative, you need to know how each compressor works, their pros and cons, and how they can impact your critical business processes.

Anglian Compressors, a Branch of Atlas Copco Compressors, has been one of the UK’s leading compressed air specialists for almost five decades. You can rely on us for honest, reliable, and up-to-date advice based on the latest technologies. Give us a call to learn more about the benefits of dual-speed compressors. Keep reading to understand how dual-speed solutions compare to other compressor types.

Understanding Commercial Air Compressor Types

Here is a quick overview of the different types of compressors used in industries such as pharmaceutical, industrial, engineering, food and drinks, and many more.

Fixed-Speed Compressors (Single-Speed)

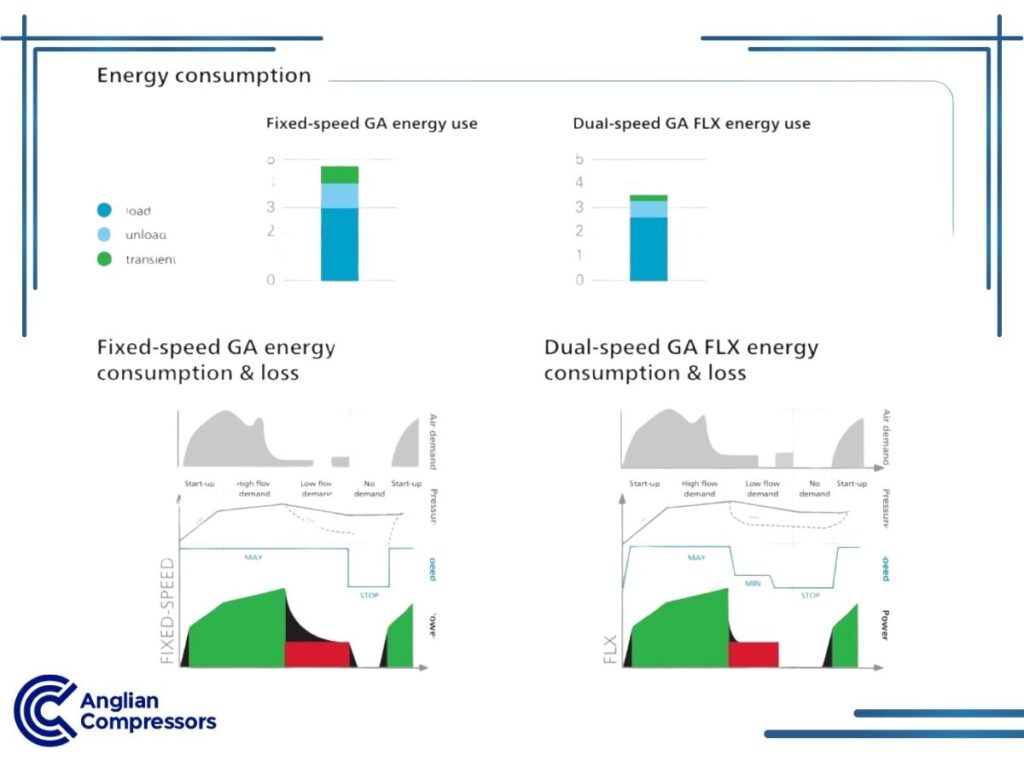

A standard fixed-speed air compressor is either loaded (making air), off-load (running, but producing no A fixed-speed air compressor operates in three modes: loaded (producing air), off-load (running but producing no air), or off (stopped). Unlike more advanced options, a fixed-speed compressor can only run at 100% capacity when in use.

When the upper-pressure set point is reached, the compressor enters the off-load mode, consuming approximately 35% of the full load current without producing air. This off-load energy consumption leads to inefficiency and higher operating costs.

Benefits and drawbacks of single-speed compressors

- Advantages: Lower initial purchase cost, simple operation.

- Drawbacks: High energy wastage during off-load, leading to higher operating costs over time.

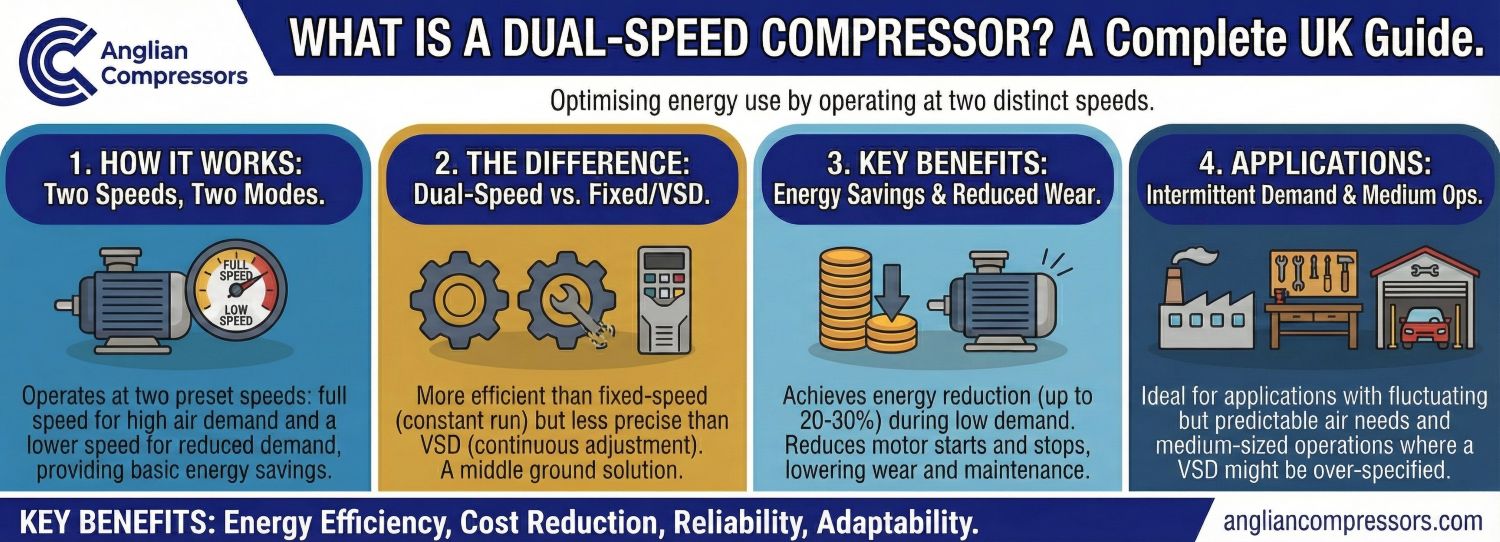

Dual Speed Rotary Screw Compressors: A Smarter Choice

A dual speed rotary screw compressor, like the Atlas Copco GA FLX, offers a balance between fixed speed and variable speed models, reducing energy losses and operational costs. Unlike fixed speed compressors, which run at 100% capacity or transition to unload, dual speed models lower speed before offloading, cutting blow-off losses and reducing energy waste.

How It Works

- Full speed during peak compressed air demand.

- Lower speed before transitioning to unload, reducing start-stop wear and energy costs.

By adapting motor speed, dual speed compressors optimise airflow (FAD), making them more efficient and cheaper to operate long-term.

Key Benefits

- Lower energy costs – reduces unload losses.

- Increased efficiency – motor speed adapts to demand.

- Longer lifespan – less wear and tear than single speed models.

Variable-Speed Compressors

Variable-speed compressors adjust motor speed dynamically to match air demand. Atlas Copco’s VSD range can operate at capacities as low as 20%, unlike standard systems that typically operate between 40–100% capacity.

This prevents start-stop operation, reducing internal wear and delivering substantial energy savings. The technology works like a dimmer switch rather than a simple on/off mechanism, offering precise air output control.

Benefits of variable-speed compressors

- Steady pressure with minimal fluctuations.

- Exceptional energy efficiency, even during low usage periods.

- Reduced wear and maintenance needs due to smooth operation.

If you are unsure of what type of compressor you need, feel free to contact us. We are always ready to offer expert advice and answer any questions you have about compressed air systems.

Dual-Speed vs Single-Speed Compressors: Which is Right for You?

A single-speed compressor operates at 100% capacity or off-load, meaning it simply cannot start under pressure and wastes energy when not actively producing usable air. In contrast, a dual-speed rotary screw compressor adjusts motor speed before transitioning to off-load, lowering blow-off losses and reducing energy use by at least 20%.

Key Differences

| Feature | Single-Speed Compressor | Dual-Speed Compressor |

|---|---|---|

| Energy Use | High unload losses, inefficient off-load running | Lower transient energy losses, more efficient |

| Operational Costs | Higher due to constant running | Lower with adjusted motor speed |

| Air Demand Handling | All or nothing operation | Flexible pressure settings, adapts to air flow (FAD) |

| Best For | Steady high air demand | Fluctuating air demand |

Which Should You Choose?

- If your air demand is constant, a single-speed compressor may be more economical to buy upfront but leads to higher operational costs.

- If your air demand lowers throughout the day, a dual-speed compressor is a much more efficient alternative to traditional fixed-speed models, delivering energy savings compared to single-speed units.

Dual-Speed versus Variable-Speed Compressors

Variable-speed compressors surpass dual-speed models in energy efficiency by adjusting motor speed dynamically to match real-time air demand.

- Cost: Variable-speed compressors are more expensive initially but deliver faster ROI (under six months in most cases).

- Efficiency: With the ability to operate as low as 20% capacity, VSD systems outperform dual-speed compressors in minimizing energy waste.

When to Choose Variable-Speed Compressors:

- For environments with highly variable air demand.

- If energy efficiency and precise air pressure control are top priorities.

Choosing the Right Compressor for Your Needs

Here are some key factors to consider when selecting a compressor:

- Energy Efficiency:

- Variable-speed compressors are the most efficient.

- Dual-speed compressors rank second.

- Fixed-speed compressors are the least energy-efficient due to off-load waste.

- Initial Costs:

- Single-speed compressors have the lowest upfront cost.

- Dual-speed compressors are more expensive but pay for themselves over time.

- Variable-speed compressors are the priciest initially but yield the fastest ROI.

- Air Pressure Control:

- Only variable-speed compressors offer precise pressure control.

- Single-speed and dual-speed systems rely on upper and lower pressure set points.

VSD, Dual-Speed and Fixed-Speed Air Compressor Installation and Maintenance Tips

When installing air compressors, consider space, ventilation, and accessibility for maintenance. Ensure proper airflow to prevent overheating, and schedule regular maintenance tasks such as filter replacement, oil checks, and cleaning.

Like any machine, air compressors require regular maintenance to remain functional and efficient for as long as possible. Some basic maintenance tasks for air compressors include replacing air filters, checking oil levels, and cleaning external components. Additionally, it is crucial to keep the compressor clean and free of debris to prevent the unit from sustaining damage.

If you’re uncertain about installation or upkeep, rely on professionals for assistance. Anglian Compressors, a Branch of Atlas Copco Compressors, team of trained technicians can handle all aspects of compressor servicing, ensuring peak performance and longevity.

Do you need a new compressor to improve the performance and energy efficiency of your compressed air systems? Are you still somewhat confused over the differences between single-speed, dual-speed and variable-speed compressors? Whether you have a specific solution in mind or just need some general advice, please get in touch with our highly trained specialists.

Anglian Compressors has been a trusted Atlas Copco distributor for nearly 50 years, operating within a 150-mile radius of Peterborough. Contact us today to learn more about how we can meet your compressed air needs and improve your operations.

FAQ

What is the difference between a dual speed and a two-stage compressor?

A dual speed compressor adjusts its motor speed based on air demand, reducing energy consumption during off-load periods. In contrast, a two-stage compressor compresses air in two stages to increase pressure, making it more efficient for high-pressure applications. Dual speed compressors focus on energy efficiency, while two-stage compressors are designed for consistent air delivery under system pressure.

How do dual speed compressors help reduce energy losses?

Dual speed compressors minimise energy losses by automatically reducing to a low speed when the system reaches its upper-pressure limit. This avoids the waste seen in fixed speed models, which continue consuming energy even when not producing air. The result is significant energy savings and lower operating costs over time.

What are the benefits of using a dual speed screw compressor?

A dual speed screw compressor offers the flexibility to adjust its speed based on demand, leading to reduced energy costs and wear on components. This makes it more efficient than traditional single speed models while offering a quicker return on investment, especially in operations with variable air demand.