What is a Compressed Air Audit and What are the Benefits?

A compressed air system won’t last forever, it has a usability lifetime. Perhaps it was fit for purpose when installed, but has compressed air usage changed since then? The maintenance necessary also becomes impactful the older the equipment becomes. Have you evaluated whether your compressed air system is still efficient, or is it unnecessarily driving up costs? Has your compressed air system still got what it takes, or is it wasting your money? Is it time for an air audit?

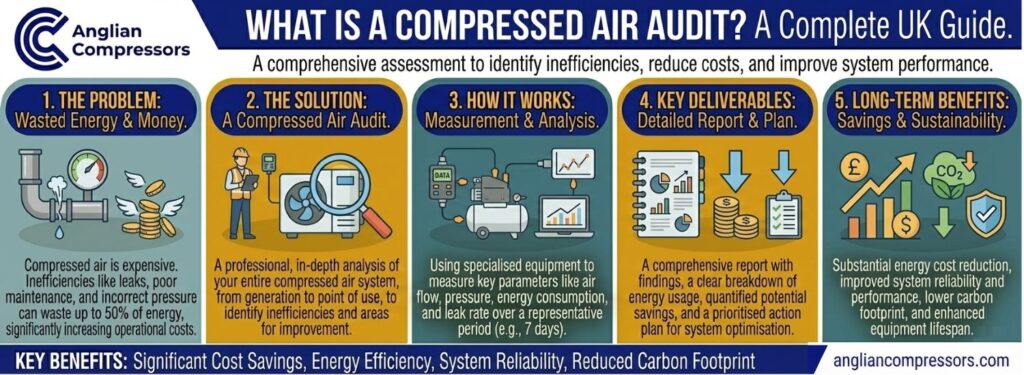

What is a compressed air audit and what are the benefits? Generating compressed air is costly; It also uses plenty of electricity. Some estimates suggest that around ten percent of manufacturing costs go into compressed air production. CO2 emissions and other environmental effects are also worth considering.

Anglian Compressors, a Branch of Atlas Copco Compressors, provides air audits to customers who already have a compressed air system installed. These audits offer varying levels of detail, from an initial visual inspection to an in-depth analysis tailored to your operational needs. There are several levels of testing, from an initial review to a detailed analysis, to properly assess how a system is performing. Then, following an initial review, a full air audit may be undertaken.

For industrial settings, an audit of compressed air systems usually more than pays for itself with the significant savings it achieves.

Understanding the Need for a Compressed Air Audit

Compressed air is vital in industrial operations, but inefficiencies can lead to higher energy costs and unnecessary strain on equipment. A walk-through assessment helps identify current energy use, detect air leaks, and avoid overpressurisation, which can force the compressor to work harder than necessary.

An audit also assesses airflow, pressure requirements, and system efficiency, ensuring your compressed air needs are met without excess waste. Compressed air systems cost billions of dollars in energy annually, and even a simple leak can add up quickly.

Regular audits ensure a more efficient compressed air system, improving performance and cost savings.

The Process of a Compressed Air Audit

A compressed air audit involves assessing the installation, equipment, nearby air quality, and other factors. A key metric is comparing the kilowatts (energy) consumed for every 100 cubic feet per minute (cfm) of compressed air produced.

Key elements examined include system dynamics (airflow, pressure, and energy consumption) and the equipment’s efficiency at delivering compressed air at the required levels.

- Audit Report: The findings are consolidated into a detailed report with recommendations, estimated costs for corrective actions, and projected cost savings.

- Site Survey: The audit starts with a site survey to assess the installed equipment, piping structure, and how each piece of equipment is intended to operate versus actual usage patterns.

- System Analysis: The dynamics of the system are analysed, focusing on airflow, pressure, cfm, and energy consumption. Additional tools, like iiTrak monitoring systems, may be used for detailed performance tracking over time.

The Different Levels of Compressed Air Audits

There are different levels of compressed air audits. We explain these below:

Level 1 – Free visual inspection on-site. The #airCHECK includes a visual inspection, air quality check, a review of ISO standards compliance, drainage check, checking for unproductive running, and air pressure levels vs. expectations and so on.Another small report often produced is the Energy Potential Calculation (EPC). This provides insight into what cost savings might be achievable. This free review intends to provide a first look at whether there are enough potential ways to save money to go on to level 2.

The Energy Potential Calculation (EPC) estimates potential cost savings from improving the system’s efficiency.

Level 2 – Our engineer may recommend adding the iiTrak monitoring system. This attaches to the existing equipment to track air usage and running hours for one week. From this data collection, the engineer extrapolates how the equipment is used in real terms, and whether it could be operated more efficiently. The engineer’s report considers whether optimal equipment is present, or if replacement equipment would offer lower operating costs, reduced energy expenditures, or other benefits, such as a cut in daily CO2 emissions, making it a net positive.

This advanced tool tracks air usage, operating hours, and efficiency for one week, identifying areas where energy or operational improvements can be made.

Level 3 – Complete AIRscan Audit. This is our most advanced audit, which complies with the ISO 11011 UK energy standard. Analysis of the data collected includes a dew and pressure point review, testing air quality, a review of compressed air processes (including the compressor room), flow rate determination, and air leak detection. While this is a paid service, in most cases, implementation of the audit’s recommendations provides sufficient cost savings for you to come out ahead. This comprehensive level often uncovers opportunities for savings exceeding the audit’s cost.

It includes air quality analysis, dew and pressure point testing, flow rate assessment, and leak detection, providing a comprehensive understanding of the system’s inefficiencies.

The Benefits of a Compressed Air Audit

A compressed air audit effectively identifies inefficiencies, reduces energy costs, and improves system performance. Many industrial air compressors operate inefficiently due to leaks, artificial demand, and incorrect air pressure requirements, unnecessarily increasing cost per kWh.

- Lower Energy Costs – audits determine how much power is needed, avoiding overpressurisation and reducing energy costs.

- Improved System Reliability – identifying bad piping, airflow fluctuations, and old piping helps keep compressors running efficiently and prevent downtime.

- Better Air Quality – ensures clean compressed air use with the right high-efficiency line filters, separators, and lubricants.

- Reduced CO₂ Emissions – optimising air pressure requirements cuts waste and supports sustainability goals.

- Targeted System Upgrades – a system assessment provides data-logging insights into whether you need to switch to a more efficient machine or upgrade a flow controller.

Air audits are an effective way to boost efficiency and performance while achieving a fast payback. Contact us today to learn more about the benefits.

Real-world Case Studies

Case Study 1: Based on an iiTrak study performed, Fabricon Design Ltd decided to upgrade to a rotary screw air compressor system to feed into their CNC cutting equipment. This provided an estimated 51 percent reduction in energy usage, with a projected cost saving of £2479 annually.

Case Study 2: Following a compressed air audit, a major cement producer decided to upgrade to variable speed drive compressors. Along with an estimated 130+ tons of CO2 emission cuts, energy savings were expected to be £23,500 annually.

Conclusion

With ongoing technological advancements in compressed air systems, regular audits provide actionable insights into whether system upgrades or process improvements are necessary.

Compressed air audits ensure your system is cost-effective and environmentally friendly. By adopting a three-tier approach, businesses can achieve significant savings and operational improvements. With technological advancements, audits can identify when upgrading equipment is beneficial.

Take advantage of Anglian Compressors, a Branch of Atlas Copco Compressors, and our air audit services today to uncover potential cost savings and efficiency improvements.

A properly conducted audit is vital to assessing where inefficiencies are present in your compressed air system. Anglian Compressors, a Branch of Atlas Copco Compressors, air audit services can help you uncover potential improvements that save money while boosting efficiency.

Book your air audit today. Contact us below.

FAQ

How does an energy audit help improve my air compressor’s performance and efficiency?

An energy audit involves a thorough evaluation of your compressed air system to identify inefficiencies such as leaks or pressure loss. By addressing these issues, the audit highlights opportunities to optimise your air compressor’s performance, reducing energy consumption and operational costs while improving overall system efficiency.

What role does an air dryer play in maintaining the efficiency of my compressed air system?

An air dryer is critical for maintaining the performance and efficiency of your compressed air system by removing moisture from the air. This helps prevent rust and scale buildup in pipes, which could otherwise cause pressure loss and damage the entire compressed air system, leading to higher maintenance costs.

Why is evaluating the entire compressed air system the first step in improving energy efficiency?

Evaluating the entire compressed air system is essential because inefficiencies can occur at multiple points, from the compressor to the pipes and filters. An audit, often recommended by the Department of Energy, identifies where energy is wasted and suggests upgrades, such as using an efficient compressor, to achieve optimal performance and reduce energy costs.