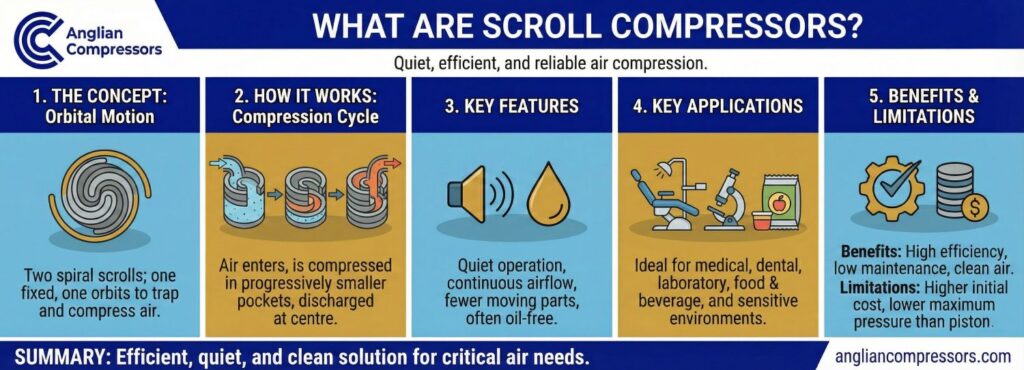

What are Scroll Compressors?

Are you looking for a way to improve the energy efficiency of your compressed air systems? By switching from a traditional piston compressor (reciprocating compressor) to a scroll compressor (often a rotary compressor alternative), you could not only reduce your electricity bills but also minimise maintenance, gain greater control over the pressure of your compressed air, and improve your compressed air quality. But what is a scroll compressor, how do they work, and what are their pros and cons?

Anglian Compressors, a Branch of Atlas Copco Compressors, has been at the cutting edge of compressed air technology since 1977 and a premier distributor of Atlas Copco solutions for nearly 50 years. In this article, we explain everything you need to know about scroll air compressors so that you can decide whether upgrading is worth the expense for your business. If you have any questions or want to know how much a scroll compressor could save you in the long run, do not hesitate to call us.

Understanding Scroll Compressors

A scroll compressor often called a scroll pump or known as a spiral compressor works by internally compressing air or refrigerant between a stationary scroll and an orbiting scroll, a process known as positive displacement.

This type of compressor is two main types of scroll compressors: oil-free and oil-lubricated. While oil-lubricated systems tend to be more common and budget-friendly, oil-free scroll compressors are the preferred choice in industries where air purity is critical, such as food and beverage, medical, and pharmaceutical sectors requiring ISO 8573-1 Class 0 oil-free air.

How do scroll compressors work?

Scroll compressors operate with a pair of spiral-shaped scroll members (often Archimedean spirals), one stationary (fixed scroll) and one orbiting (orbiting scroll). The orbiting scroll, driven by a motor, moves around the stationary scroll eccentrically. This motion of the scroll creates crescent-shaped pockets.

As the scroll continues to orbit, atmospheric air is drawn in through the suction port. The orbiting scroll moves to trap this air in a compression chamber. As the scroll orbits, the pocket moves towards the centre and its volume decreases, compressing the air. This process of compressing is continuous. This method of compression is particularly energy-efficient due to reduced mechanical losses and heat transfer.

The compressed air is released through an outlet port equipped with a non-return valve (check valve), which maintains consistent pressure and prevents backflow. This ensures reliable performance and minimal air loss. Whether the application requires an oil-lubricated or oil-free system, scroll compressors offer consistent, high-quality output and pulsation-free air.

Scroll compressors are becoming increasingly popular in applications like HVAC systems, air conditioning, refrigeration (where they compress the refrigerant), and transportation of food, due to their low noise, efficiency, and durability. Their simple design, with fewer moving parts, leads to less wear and tear, making them a reliable choice for industries with specific air quality needs.

Modular versus Single Scroll Compressors

Modular Scroll Compressors: Utilise variable flow technology, allowing the output to adjust dynamically to demand. They often feature a central controller for monitoring and optimising performance across multiple modules. This setup allows for redundancy; if one compressor runs into an issue, others continue working.

Single Scroll Compressors: Provide fixed output, making them simpler and more affordable upfront but potentially less energy-efficient during varying load demands. This design of the scroll compressor uses one scroll set for smaller applications.

Scroll compressor applications

Scroll compressors are versatile and commonly used across a range of industries due to their efficiency, compact design, and reliability. These compressors are widely used in:

- HVAC (Heating, Ventilation, and Air Conditioning) where the compressor is also used to compress refrigerant.

- Refrigeration systems and cold storage

- Food and beverage production (e.g., ice-making machines and packaging) requiring oil-free compressed air.

- Medical and dental equipment (compliant with HTM 02-01 standards in the UK).

- Electronics cooling and data center management

- Metal fabrication and plastic molding

- Transportation refrigeration (refrigerated trucks)

Their compact and relatively lightweight design and ability to deliver clean air make them a preferred solution in industries with strict operational and environmental standards and sensitive working environments.

Scroll compressors advantages

Scroll compressors offer several key benefits that make them a popular choice across industries:

Energy Efficiency & High Efficiency

Scroll compressors operate with a smooth, continuous compression process, which minimises friction, leakage, and mechanical losses. Oil-free models, in particular, align with energy efficiency goals by meeting Class 0 air purity standards. This high working efficiency makes them ideal for many manufacturing processes.

Reliability and Durability

With fewer moving parts inside the scroll design, these compressors are more reliable and less prone to mechanical failure. The design also minimises the need for clean environments, making them durable for various applications, including air conditioning systems and other demanding settings.

Quiet Operation & Noise Levels

Scroll compressors, especially in HVAC applications, are known for their quiet performance. They generate less vibration and low noise, which is crucial for noise-sensitive environments like medical facilities and offices. Some models operate as low as 53 dB(A).

Compact Design

The compact design of scroll compressors allows for easy installation in tight spaces, making them ideal for applications such as air conditioners and refrigeration, where space is limited. Their smaller size doesn’t compromise performance, ensuring high-quality compressed air.

Consistent Air Quality

Scroll compressors produce high-quality compressed air with minimised leakage, which is essential for industries with strict air quality requirements. Oil-free models are particularly beneficial in applications requiring absolutely Class Zero air purity, such as food and pharmaceuticals.

Reduced Maintenance

The simple, robust design, including components like the elektronikon® control, requires less maintenance. This leads to lower overall costs, minimal downtime, and an economical long-term solution for businesses.

Technical Specifications & UK Compliance

For UK businesses, compliance with safety and environmental standards is paramount. Atlas Copco’s scroll compressor technology (such as the SF and SF+ series) is designed to meet:

- ISO 8573-1 Class 0: Ensuring 100% oil-free air for critical applications.

- HTM 02-01: Meeting the redundancy and purity requirements for NHS and private medical air systems.

- PSSR 2000: Our team can assist with the Written Scheme of Examination (WSE) required for pressure systems.

Key technical specs often include a flow rate ranging from 3 to 99 l/s, pressures up to 10 bar (high pressure), and IE3 or IE4 energy-efficient motors.

Disadvantages/advantages of Scroll Compressors & Comparisons

Scroll compressors almost always work out cheaper than piston compressors in the long run while providing greater control over the pressure of your compressed air systems. However, when compared to other compressors like a rotary screw compressor, there are factors to consider. Nevertheless, you should be aware of the following advantages and disadvantages before committing to a purchase:

Higher purchase price

Scroll compressors typically have higher upfront costs compared to piston compressors (which use pistons to compress air). However, their long-term energy savings and reliability often outweigh the initial expense.

Complex Maintenance

Scroll compressors, though less prone to wear, can be challenging to service due to their precise design. Repairs often require specialised tools or component replacement (such as tip seals).

Scroll vs. Screw Compressor

While a screw compressor is better suited for continuous, heavy-duty industrial loads (high-pressure, large volume), a scroll compressor is mainly used for smaller, noise-sensitive applications where intermittent or modular use is preferred. The scroll also lacks the complex oil separation systems found in oil-injected screw compressors.

Discover Our Range of Technologically Advanced Scroll Compressors

If you want to reduce your energy costs while gaining more control over the accuracy, pressure, and purity of your compressed air systems, you might benefit by switching from a piston compressor to a scroll compressor (positive displacement compressor). Fortunately, if you are looking for versatile, cost-effective and durable solutions, you have come to the right place.

At Anglian Compressors, a Branch of Atlas Copco Compressors, we have been an industry-leading supplier and installer of top-quality compressors by manufacturers such as Atlas Copco for over half a century. Whether you have questions about our products or want to know more about the latest technology, we are only a phone call away. Contact us today to learn more about us and our products.

FAQ

What is the lifespan of a scroll compressor?

With proper maintenance, including tip seal replacement every 10,000 hours, a scroll unit offers a long operational life.

Do scroll compressors need dryers?

Yes, to prevent moisture buildup. Many Atlas Copco SF+ units come with integrated refrigerant dryers.

Are scroll compressors suitable for continuous use?

Yes, specifically modular systems which can cycle between units to allow for 100% duty cycles without overheating.