What are Quiet Compressors?

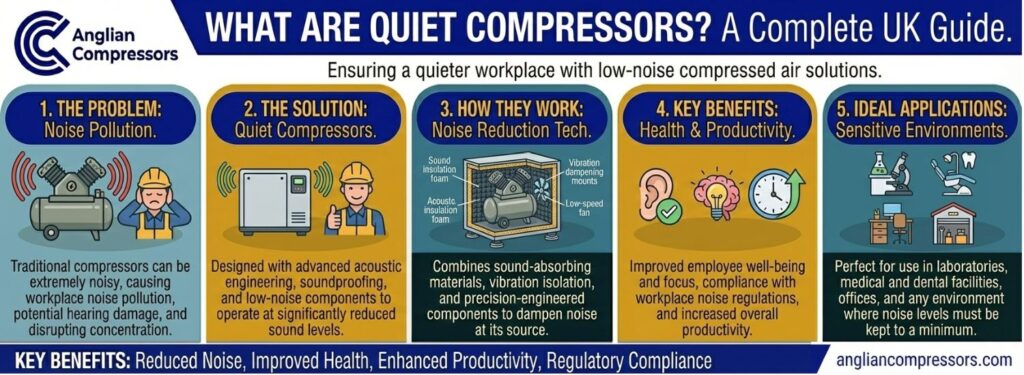

Anyone who has previously worked in a noisy industrial and commercial environment appreciates the need for effective sound management. Depending on their type and relative size, some air compressors push the limit of acceptable decibels in the workplace.

For employers, it’s worth knowing that there are quiet compressors available, as well as methods to manage the noise emanating from an existing air compressor.

Workplace Noise and Worker Safety and Productivity

Any loss of hearing is usually permanent, making its prevention paramount in the workplace.

People pick up sound vibrations inside the ear. Each ear contains tiny hairs that convert vibrations to sounds. Potential hearing loss occurs when exposed to loud noise, usually for extended periods.

Noise above 85 decibels (dB) is particularly harmful, with prolonged exposure leading to irreversible damage. In fact, standard compressors often exceed this limit, creating a hazardous environment.

Noisy environments may flatten the hairs inside the ear, which sometimes leads to developing tinnitus (1 in 10 UK adults have tinnitus) or hearing loss (approximately 1 in 6 people have hearing loss connected to noise exposure).

Impact of noise on productivity and communication

Compressor noise in the workplace causes stress, fatigue, and decreased performance. Noise pollution is one of the biggest distractors from focus and entering the “flow” state. The impact of noise on productivity is lethal for production lines. Here are some of the worst effects:

- Muffled hearing: Noise can make it difficult to hear others, which can lead to misunderstandings and communication errors. Ultimately costing you time and money.

- No space for thinking: Passive thinking whenever you’re taking a quick break or daydreaming about work is incredibly difficult to do in noisy environments. If you’re a critical thinker, you know that those moments when you zone out because you’re lost in thought are priceless for finding solutions or brilliant ideas.

In many cases, quieter equipment can significantly improve safety and overall productivity.

Aside from being a hearing risk, loud air noise in your factories will cost you money and efficiency in the long-term.

UK Regulations for Noise Control

Based on the UK Control of Noise at Work (2005 regulation), every employer is required to carefully consider worker safety relating to noise exposure. Of relevance is noise levels at 80 decibels – such as machine noise – in a working environment.

Other distinctions are made, and regulatory requirements are enhanced, at still higher decibel levels.

To protect their workers, employers must offer relevant information, appropriate training, and equipment, such as noise-muffling headsets, earplugs, etc. This becomes mandatory at the 85 dB level, and above.

Additionally, employers must provide hearing protection and checks for company workers in environments that are this noisy too. Compliance with these Health and Safety Executive (HSE) standards is critical to avoid legal liability.

Failure to comply with these regulations can result in fines, other penalties, and the risk of harm to workers.

Therefore, attention paid to a reduction of machine noise is worthwhile.

What Makes Air Compressors Quiet?

There are different factors why air compressors make noise in the first place. It could be because of the power source, the friction, the quality, or even how it was installed. We’ll talk about all of these below.

Factors that affect air compressor noise:

Compressor Proximity – It matters where the silent compressor is located relative to most on-site workers. If a compressor system runs mainly in an automated manner, locating it away from the main working area is beneficial.

Using soundproofing materials to deaden machine noise further reduces the decibels reaching other areas of the job site.

Compressor Room or Open Area – Installation in a plant room is a better option. Surrounding walls and additional soundproofing reduce distributed sound levels. It won’t, however, reduce the decibels inside the room for people managing the compressor.

This is where quiet air compressors are useful in reducing the noise problem at the source. Placing the compressor in a separate room is a common strategy, but an intrinsically quiet machine offers more flexibility.

Friction – Some air compressors are noisier due to parts rubbing against each other. This is part of their design but contributes to overall noise levels. Size and RPMs also have relevance: small, low-noise air compressors used to inflate tyres at a vehicle workshop are compact and produce high psi, with high decibels to match. Traditional compressors, especially reciprocating compressors using a piston, create significant vibration and mechanical clatter.

By comparison, an Atlas Copco VSD+ rotary screw compressor or a scroll compressor has barely any moving parts, and are far quieter options.

Sound Dampening – Rubber isolation pads for smaller compressors to sit on and/or soundproofing wall panels decrease vibration noise and sound emanations. They can reduce the sound levels that carry across the job site.

However, this will only partially lower the decibels generated by one or more air compressors. Don’t expect miracles! To significantly reduce noise, addressing the source is more effective than baffling.

Power Source Used – Air compressors are either gas-powered or electric-powered. Electric ones are quieter than those relying on gas. This is because a gas-based air compressor uses an engine to generate power to function.

Air Compressor Type – Not all models are built to be a silent air compressor. Some older models and types can tip the scales at 85 dB. Others are quieter, like the Atlas Copco VSD+ range, often below 65 decibels.

Near the end of its useful life, there’s a good argument for replacing an ageing and noisy air compressor with a silent air compressor (or at least a low-noise model).

What’s the difference: silent air compressors, noiseless, or ultra-quiet compressors?

Absolutely nothing. These three terms are often used as marketing hype, but in reality, there is no difference between all three. That’s because these terms are not industry-standard labels. That means anyone is free to advertise that two compressors are “silent” even though one operates at 60dB and the other at 80dB. No machine is completely silent, but technology has come a long way.

In reality, to find a quiet air compressor, you need first-hand experience and technical data. Although learning the specs like power level, RPM, and enclosure then comparing them with each other helps, it isn’t a substitute for experience.

Luckily, you can easily find testimonies on forums and groups or consult technical data sheets for ISO 2151 certified noise levels.

Types of Quiet Compressors

If you’re interested in using silent air compressors, it’s necessary to steer toward quieter air compressor types from the outset. Otherwise, there’s a risk of selecting a type of compressor for its performance and only later discovering its noise level is too high.

Here are some compressor types, which are viable options for the best quiet air compressor:

Oil-Lubricated vs. Oil-Free Designs

Oil-lubricated and oil-free compressors are the two main types of quiet compressors. Oil-lubricated compressors are typically quieter than oil-free compressors. This is because the oil helps to lubricate and cool the moving parts of the compressor, which reduces friction and noise. Oil-lubricated compressors are also typically more durable and efficient than oil-free compressors.

However, oil-free compressors are cheaper to maintain and have a lower initial cost of purchase compared to oil-lubricated. This is because oil-free compressors have fewer moving parts. Another benefit of oil-free air compressors is that they’re much smaller, so they’re perfect for smaller businesses.

Pro Tip: For quieter operations without compromising clean air purity, consider Atlas Copco’s advanced oil-free models with soundproofing features, such as the SF Scroll series.

Rotary Screw Compressors

The rotary screw air compressor relies on two elongated helical screws that turn in opposing directions. This creates air pockets, allowing air compression to occur. Whilst it’s highly effective as an air producer, the screws themselves do not make contact. This helps to avoid friction-related sound emanations.

There are both oil-injected and oil-free versions of rotary screw machines. This is relevant for industries that require oil-free compressed air, such as medical and other fields. However, from a machine noise standpoint, both operate quieter than most other compressors.

Modern, larger silent air compressors, such as the rotary screw VSD+ GA compressors from Atlas Copco, don’t operate much above 62 decibels. Alternatively, their smaller, oil-injected screw compressors (G 2-7 models) are capable of up to 10 bar at only 67 decibels.

Both allow workers to be closer to the compressor area and not necessarily need to wear hearing protection.

For example, Atlas Copco VSD+ rotary screw compressors operate as low as 62 dB, making them ideal for quiet workplaces. These compressors work well in open-plan facilities where standard compressors would be too intrusive.

Scroll Compressors

When specifically looking for the quietest air compressors, a scroll compressor is an easy recommendation that fits this category. These are considered ultra-quiet compressors because they are designed to operate quietly from the outset. While no compressor is silent per se, their internal mechanisms and design approach get as close as possible.

They will operate around the clock, making them suitable for 24/7 operations, and ones needing an ultra-reliable system. The downside to scroll compressors is that their CFM rating (cubic feet per minute of compressed air production) is lower than a rotary screw or other compressor types.

The Atlas Copco SF and SF+ range of oil-free scroll compressors is worth a look. They get down to as low as 53 decibels, depending on the compressor selected. These are extremely quiet, making them perfect for noise-sensitive environments like laboratories and hospitals.

Atlas Copco SF and SF+ scroll compressors can operate as low as 53 dB, offering ultra-quiet performance.

Installation and Maintenance for Quiet Operations

Even the best quiet compressors reduce noise only if installed and maintained correctly. Neglect can cause a quiet unit to become noisy over time.

- Ventilation is Key: Silent compressors are often enclosed in acoustic cabinets that trap heat. Ensure your installation includes proper ventilation or ducting to prevent overheating, which can lead to mechanical stress and increased noise.

- Vibration Isolation: Ensure the compressor sits on appropriate rubber mounts or isolation pads. This prevents the “drumming” effect on the floor.

- Regular Service: Worn bearings, loose belts, or deteriorating tip seals (in scroll compressors) will increase the noise of your air compressor. A consistent maintenance schedule ensures the machine remains within its original decibel specifications.

How to Choose the Right Quiet Air Compressor

To choose the right quiet air compressor, consider when selecting a silent model the following factors:

- Performance Needs: determine the air pressure (PSI) and air supply (CFM) requirements for your pneumatic tools and operations.

- Decibel Levels: look for compressors with sound ratings below 70 dB for quieter work environments to reduce noise levels.

- Space Availability: compact models may be better for smaller facilities.

- Maintenance Requirements: oil-free compressors are easier to maintain, while oil-lubricated ones are quieter and more durable. Compressors without complex gearboxes may be simpler, but VSD (Variable Speed Drive) units offer better energy efficiency.

- Technology: Decide between rotary screw or scroll based on your duty cycle. Reciprocating compressors are cheaper but louder; compressors are suitable for 24/7 use only if designed for it (like screws).

Investing in a quiet compressor is an investment in your workforce’s health and efficiency. Whether you need a compressor for a dental surgery or a heavy industrial plant, ensuring the air compressor is designed for low-noise operation will pay dividends in the long run.

For tailored recommendations, consult the experts at Anglian Compressors, a Branch of Atlas Copco Compressors.

Contact Anglian Compressors, a Branch of Atlas Copco Compressors, for expert guidance on selecting a silent air compressor and installing the best quiet compressor for your needs.