Understanding the impact of air compressor filtration on your compressed air system

Compressed air systems play a crucial role in various industrial applications, from construction and manufacturing to food processing and healthcare. The quality of compressed air these systems produce directly impacts their reliability and efficiency.

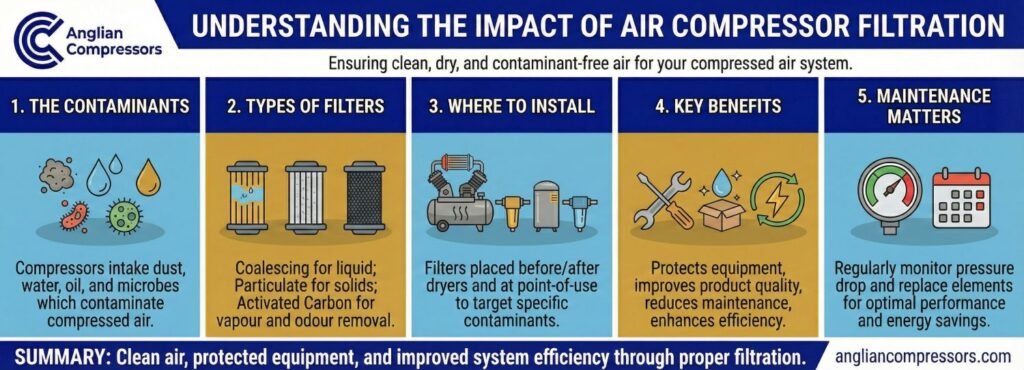

One of the core components of an air compressor is the compressor filtration, which prevents impurities such as oil, moisture, and solid particles from contaminating the compressed air.

But how much of an impact does the filtration make? How do you choose the right one? And how do you know when it is time to replace your compressed air system’s filter? We will answer all those questions and more in this article.

Anglian Compressors, a Branch of Atlas Copco Compressors, has been a premier distributor of air compressors and components for renowned manufacturer Atlas Copco since 1977, so you can trust us for honest and accurate advice. Do not hesitate to call us if you have any questions regarding your particular compressed air system. Keep reading below to learn more about the ins and outs of air compressor filter cartridges.

Air Compressor Inline Filters Explained

Inline air filters are essential in air treatment, ensuring clean air by removing oil aerosols, moisture, and solid particles from the compressed air stream. Without proper air filtration, contaminants can reduce filter efficiency, damage industrial air compressors, and affect air quality for your application.

How Filters Work

As incoming air enters the system, filters use adsorption to remove oil vapours. Particulate filters trap solid particles like dust and dirt, and coalescing filters separate liquids from compressed air, preventing corrosion and blockages.

Types of Filters for Your Air Compressor

- Coalescing Filters – used to remove fine oil mist and water droplets.

- Particulate Filters – remove dirt and debris from the compressed air stream.

- Activated Carbon Filters – use carbon to eliminate odours and vapours.

- Compressed Air Dryers – work alongside inline air compressor filters to ensure clean and dry air.

Why the Right Air Filter Matters

The correct filter prevents air contaminants, enhances filter efficiency, and helps meet air quality requirements. Filters play a vital role in extending the life of rotary screw compressors and reducing energy costs.

How Inline Filters Impact Energy Efficiency

Compressed air contains contaminants that increase energy costs and reduce efficiency. Filters remove oil, moisture, and dust, preventing pressure drops that force the compressor tank to work harder.

Boosting Efficiency and Reducing Costs

- A clean air compressor air filter ensures consistent airflow, reducing energy waste.

- Filters are effective at removing oil aerosols and water, preventing corrosion in separators in compressed air systems.

- Choosing the right filter type lowers maintenance costs and extends equipment life.

Selecting the Right Filter Type

- Coalescing filters – remove oil and moisture.

- Particulate filters – trap dust for clean compressed air passes.

- Activated carbon filters – eliminate odours and vapours.

Factors That Impact the Performance of Filtration

Several factors can influence the effectiveness of air compressor filter cartridges, notably:

Filtration Efficiency

Filtration efficiency measures how effectively the filter removes contaminants, which is usually expressed as a percentage of particles captured at a specific size range. High-efficiency filters are crucial for industries requiring stringent air purity, such as electronics and food production.

Pressure Drop

When air encounters resistance passing through a filter, it results in a pressure drop.

Balancing high filtration efficiency with minimal pressure drop is essential for maintaining energy efficiency and airflow consistency.

Service Life

A filter’s service life depends on contaminant type and concentration, airflow rates, and operating conditions. Atlas Copco’s Next-gen filters with inPASS technology offer intelligent service indicators, notifying users when filter replacement is necessary and reducing downtime and maintenance guesswork.

Learn More About Our Range of inline Filters for compressed air systems

Anglian Compressors is proud to be a premier distributor for Atlas Copco, a leading manufacturer of compressed air systems and components, including filters, that are designed in close collaboration with experienced industry experts and research institutes.

All our Atlas Copco filters are ISO-certified and validated by independent certification bureaus. Furthermore, you can count on our technicians to install and maintain your systems to the highest industry standards.

Contact us today for expert advice on choosing the best inline filters for your system, ensuring optimal performance and reliability for years to come.

Frequently Asked Questions

We are only a phone call away if you need more information to help you choose the right filter. In the meantime, here are the answers to some of our customers’ most frequently asked questions:

Does quality matter when it comes to choosing an inline filter?

A quality air compressor line filter finds the sweet spot between top-notch filtration and keeping pressure drop to a minimum. The right mix of filter material matters for tackling different kinds of dirt.

Line filters must be able to handle harsh conditions and pressure changes in compressed air systems. A stainless-steel core gives them the strength and rust protection they need for a long lifespan.

What are the consequences of failing to replace filter elements in a timely manner?

Regularly changing your line filter is key to maintaining air quality and energy efficiency. Your filter could clog up without frequent replacements (usually required annually), decreasing your system’s air pressure. Ignoring this issue can significantly increase your energy bills and CO2 emissions over time.

Compressed air filters rely on delicate channels. Harmful substances like oil can slip through, if they degrade, jeopardising air purity.

How can you tell when it is time for a new air filter element?

Line filters come with service indicators that let you know when the pressure drop goes beyond a set limit. This signals that the filter element is full and needs changing.

With Atlas Copco’s Next-gen inPASS filters, a smart indicator provides detailed information on filter usage, pressure differences, and maintenance needs. It can even send alerts to a remote device for added convenience.

Can you manually inspect and clean the filter?

The breakdown of filtration material happens on a microscopic level, making it impossible to detect with the naked eye. Attempting manual cleaning can damage the delicate fibre layers, leading to poorer performance. Rather than saving money, you may end up with higher costs and compromised air quality.

Do I need to use genuine line filters from the original equipment manufacturer (OEM)?

Non-genuine filter elements that are not tailored specifically for your system will not provide a perfect match. If they are cheaper, it is likely because they are made with inferior materials and have a shorter lifespan. An imperfect fit can lead to leaks and increased pressure drop. Plus, filter cores not built to handle high-pressure differences might collapse during use.

What types of filters should I use to ensure clean compressed air?

It is important to select the right range, including high-quality air filters like dry particulate and oil filters, to ensure clean compressed air. These filters capture contaminants from the compressed air before they enter your system, preventing damage and maintaining air quality. Filters are critical in removing particles the human eye cannot see, ensuring your air is always clean and dry.

How do I know when my compressor filter needs to be replaced?

Filters have a limited lifespan and must be replaced once they become clogged with contaminants. A differential pressure gauge can help you monitor the pressure drop across the filter and indicate when it is past its optimal use. If unsure, contact your provider to ensure you maintain high-quality compressed air.

How do inline filters affect energy efficiency in a compressed air system?

Inline filters impact energy efficiency by removing contaminants from the compressed air, preventing blockages that can cause your system to overwork. A clogged filter can increase pressure drops, which forces the compressor to use more energy. Regularly replacing filters ensures clean, dry air and helps optimise energy usage, reducing operational costs.