Troubleshooting Moisture Issues in Nitrogen and Oxygen Generators (UK Guide)

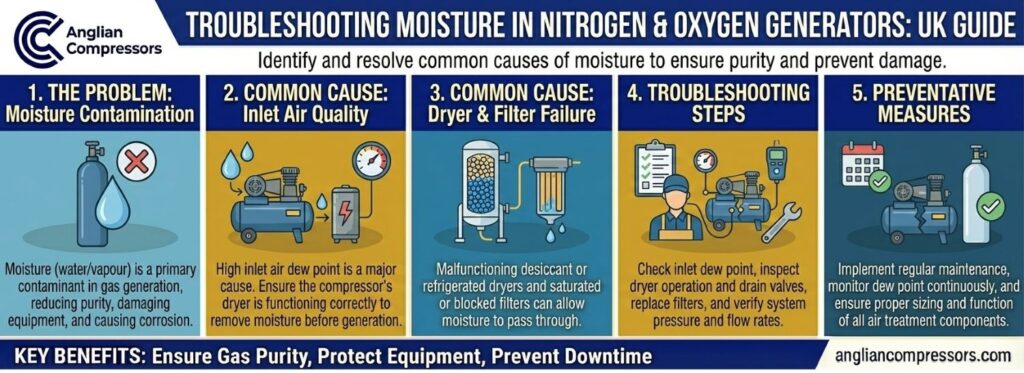

A sudden drop in nitrogen purity halts a laser cutting operation. A high-humidity alarm on a medical oxygen generator threatens a facility’s vital supply. These costly scenarios often share a common saboteur: moisture. For operators of on-site gas generation systems, effective troubleshooting of moisture issues in nitrogen and oxygen generators is a critical skill, not a luxury.

For UK dutyholders in high risk industries such as food packaging, pharmaceuticals, electronics, and medical gas supply, managing this risk is absolutely critical. This guide will give maintenance engineers and technicians a structured approach to identify, repair and avoid the typical failures that occur as a result of moisture contamination. This knowledge is vital for anyone charged with the troubleshooting of moisture problems in nitrogen and oxygen generators.

Why Moisture is a Critical Failure Point

The air your compressor draws in is never dry. It contains water vapour, and the process of compression concentrates this moisture. A typical 55 kW compressor can produce over 280 litres of liquid water condensate every 24 hours. If not systematically removed, this water will travel downstream to your generator.

So why is the UK’s highly variable climate such a problem? Here are four examples of worst-case scenarios:

- Summer Humidity: Warm and sticky summer days can see RH levels rise above 70%. This significantly increases the total water load your air treatment system is expected to manage, leading to a much faster filter saturation rate and an increased risk of overloading your dryers.

- Winter Conditions: Hot compressed air cools quickly in unheated pipework. As it hits the dew point, slugs of liquid water can form and cause serious damage.

- Poor Ventilation: A compressor room without airflow becomes a heat trap. Moisture builds quickly. Before long, the machine is pulling in its own warm, damp air—and that only makes conditions worse further down the line.

So why does this matter?

Nitrogen and oxygen generators have very low moisture tolerances. The compressed air you use must be clean and dry to protect sensitive components and to meet the very high standards of your end application.

- Food & Beverage: In Modified Atmosphere Packaging (MAP), moisture degrades gas purity. That leads to spoilage, a shorter shelf life. And ultimately, it leads to a failure to meet FSA standards.

- Pharmaceuticals & Electronics: Moisture is a serious contaminant. In sterile areas, it undermines safety. In electronics, it can damage delicate components and cause defects.

- Medical Oxygen: Too much humidity fosters bacterial growth. In oxygen systems, that’s a direct health risk and a breach of MHRA and NHS guidelines.

To maintain nitrogen purity between 95% and 99.999%, the compressed air feeding the generator also needs an extremely low pressure dew point (PDP).

How Moisture Destroys Your Generator: The Technical Breakdown

Moisture damage is a progressive failure that moves from reversible performance drops to irreversible physical destruction. Understanding how this damage occurs is central to troubleshooting moisture issues in nitrogen and oxygen generators.

For Pressure Swing Adsorption (PSA) Generators

PSA systems use adsorbent materials—Carbon Molecular Sieve (CMS) for nitrogen and Zeolite for oxygen—that are highly susceptible to water.

- Stage 1: Competitive Adsorption (Performance Drop): The adsorbent material has a stronger attraction to polar water molecules than to the gases it is meant to separate. When moist air enters, the sieve becomes “blinded” as it captures water vapour instead of oxygen or nitrogen. This immediately causes gas purity to plummet.

- Stage 2: Physical Damage (Irreversible Failure): When slugs of liquid water enter the adsorbent bed, the damage is catastrophic. Liquid water causes CMS to break down into a fine black powder that clogs valves and exhausts. It causes Zeolite beads to bind into hard, solid clumps, creating channels that let air pass through without separation. This damage is permanent and requires a complete, costly replacement of the adsorbent material.

For Membrane Nitrogen Generators

These generators are comprised of hollow bundles of polymer fibres with microscopic pores. These pores are fouled by water aerosols (typically emulsified with oil), which physically block the pores. This fouling reduces the surface area of the membrane permanently; thus, an irreversible loss in purity and flow rate occurs, and the module must be replaced.

Common Symptoms of Moisture Contamination

Be alert for these key warning signs:

- Performance Issues:

- Nitrogen or oxygen purity consistently falls below the required setpoint.

- The generator’s control panel shows frequent alarms for “Low Purity” or “High Humidity”.

- Flow rates are unstable or lower than expected.

- Physical Evidence:

- Visible water or an oily emulsion in filter bowls or discharging from drain valves.

- A fine black or white dust (damaged adsorbent) is visible in downstream filters or puffing from the generator’s exhaust.

- Condensation can be seen inside any clear tubing or on your system’s components.

A Step-by-Step Guide to Troubleshooting Moisture Issues

Diagnostics should be simple. A clear process helps track down the root cause quickly, and that matters when nitrogen or oxygen generators are involved.

Work through these steps in order—don’t jump ahead:

- Verify the Fault: Start small. Use a calibrated gas analyser to confirm purity really is low. The panel display alone isn’t enough.

- Check All Drains: Start at the beginning of your system. Manually test the automatic drains on the wet air receiver, coalescing filters, and the dryer. A blocked or failed drain is a common and critical failure point. Proper disposal of compressed air condensate is your first line of defence.

- Inspect Filters: Check the differential pressure gauges on your pre-filters. A high reading above 8–10 psi is a warning sign. It means the element is clogged. Airflow is restricted, and contaminants have likely built up. At that point, isolate and depressurise the system. Then check the element directly.

- Audit the Air Treatment System:

- Aftercooler: Ensure the aftercooler is functioning correctly and removing bulk water before it reaches the dryer.

- Moisture Separator / Drains: Confirm that the primary water separator after the cooler is draining effectively.

- Dryer Performance: This is the most likely culprit. For refrigerant dryers, check that the condenser is clean and the unit is running. For desiccant dryers, confirm the system is cycling between towers correctly and that purge exhausts are clear.

- Assess the Compressor Room: Check the compressor’s operating environment. Is the room hot, humid, or poorly ventilated? Hot intake air holds more moisture, creating a vicious cycle and overloading your dryer.

- Measure the Dew Point: Use a calibrated dew point sensor at the test port on the generator’s inlet. This is the definitive test. If the dew point is high (e.g., above -20°C when it should be -40°C), the problem is located in your upstream air treatment system. An air quality testing audit can confirm this.

- Check for Oil Carryover: If you use an oil-lubricated compressor, inspect for signs of oil carryover. Check the condensate from drains for an oily sheen and inspect the coalescing filter bowl for oil residue. This is a critical step, as oil contamination is a non-issue for systems using Class 0 oil-free compressors.

The Atlas Copco Advantage: Engineered for Moisture Control

At Anglian Compressors, a Branch of Atlas Copco Compressors, we recommend integrated Atlas Copco systems because they are engineered as a complete package to prevent moisture contamination.

- Matched Systems: Turnkey solutions like the NGM/NGP series nitrogen generators and OGP oxygen generators are designed to work seamlessly with a matched aftercooler, dryer, and filtration package. This is precisely tuned to protect the sensitive PSA molecular sieves, meeting stringent PDP requirements of -40°C to -70°C.

- Oil-Free Technology: Pairing a generator with an Atlas Copco Class 0 oil-free compressor completely removes the risk of oil vapour contamination, which combines with moisture to create a destructive emulsion that poisons adsorbent beds.

- SMARTLINK Monitoring: This remote monitoring technology provides real-time data and preventive maintenance alerts for system health. Its ability to send predictive alerts for dew point spikes warns you of a developing moisture problem before it causes damage.

Long-Term Prevention: Your Defence Against Downtime

The most effective way to deal with moisture is to prevent it from reaching your generator. This requires a multi-layered defence and a commitment to preventive maintenance.

- Desiccant Dryers: For nearly all PSA and membrane generators, a desiccant dryer is essential. A refrigerant dryer alone can’t deliver the protection these systems need. There are many types of compressed air dryers on the market. Choosing the right one—and keeping it properly maintained—makes all the difference.

- High-Efficiency Filtration: A coalescing filter is needed to catch fine water and oil aerosols. After a desiccant dryer, a particulate filter should be installed. This captures any fine desiccant dust that makes it through.

- Proactive Maintenance: A maintenance plan isn’t just another expense. It’s an investment in uptime. Following manufacturer service intervals for filters and dryers helps prevent unexpected failures. Comprehensive preventative maintenance programs go further still, keeping your system protected at all times.

Quick Reference: Diagnosing Moisture Faults

| Symptom | Likely Cause | Recommended Fix |

| Low Gas Purity + High Inlet Dew Point | Saturated or failed air dryer. | Service or replace the air dryer. Check desiccant condition. |

| Visible Water in Filter Bowls | Blocked or failed condensate drain. | Test, clean, or replace the faulty drain valve. |

| Purity Drops During High Air Demand | Air treatment system is undersized for peak flow. | Audit system capacity. Consider upgrading the dryer or adding a dry air receiver. |

| Black/White Dust at Generator Exhaust | Irreversible adsorbent breakdown from liquid water. | Isolate generator immediately. Contact a service specialist for adsorbent replacement. |

| Purity Is Low, But Inlet Air Is Dry | Adsorbent bed is saturated from a previous moisture event. Leaking internal valves. | Run generator with dry air to attempt regeneration. If no improvement, suspect adsorbent damage or valve failure. |

Meeting UK Compliance: Air Quality Standards

Maintaining a dry, clean air supply is essential for meeting UK regulatory and industry standards.

| Body / Standard | Relevance to Moisture Control |

| ISO 8573-1:2010 | Defines the maximum allowable limits for water, oil, and particulate contaminants in compressed air. |

| PSSR 2000 | Requires periodic safety inspection of pressure vessels, including air receivers and generator towers. |

| BCAS | Provides best practice guidelines for air quality, especially for food & beverage applications. |

| FSA | Sets standards for food-grade gases where moisture control is vital for preventing spoilage. |

| MHRA / NHS | Mandates strict moisture and sterility control for medical oxygen to prevent health risks. |

In the final analysis, the wellness of your gas generator will be determined by the calibre of the air that feeds it. By learning the basics of how a Nitrogen Generator Work? We know that clean, dry air is the foundation of the entire process. The big lesson of any exercise in troubleshooting is that proactive control is always better than reactive repair, if it is important to have the assurance of the absence of microorganisms in your compressed air.

Key Takeaways

- Moisture in UK compressed air systems is an unavoidable fact, but it can be totally mitigated against with the correct equipment and procedures in place.

- The installation of an appropriately specified desiccant dryer in combination with multi-stage filtration is an essential condition for the healthy operation of PSA and membrane gas generators.

- Routine dew point monitoring matters. Paired with purity analysis, it helps catch problems early. Some issues can be fixed before they ever cause damage or force costly downtime, which saves both money and disruption. A good service partner is just as vital. Their expertise keeps systems compliant and running at their best.

- Working with a service partner who has the experience and expertise to keep your systems fully compliant and performing at their best is essential.

If you are experiencing gas purity problems, or have concerns that your systems could be at risk from moisture then get in touch with our knowledgeable team.

Anglian Compressors, a Branch of Atlas Copco Compressors, offer a free moisture risk assessment. Contact us today and we’ll ensure the long-term reliability of your gas generation system.