The Role of Air Compressors in Sustainable Manufacturing

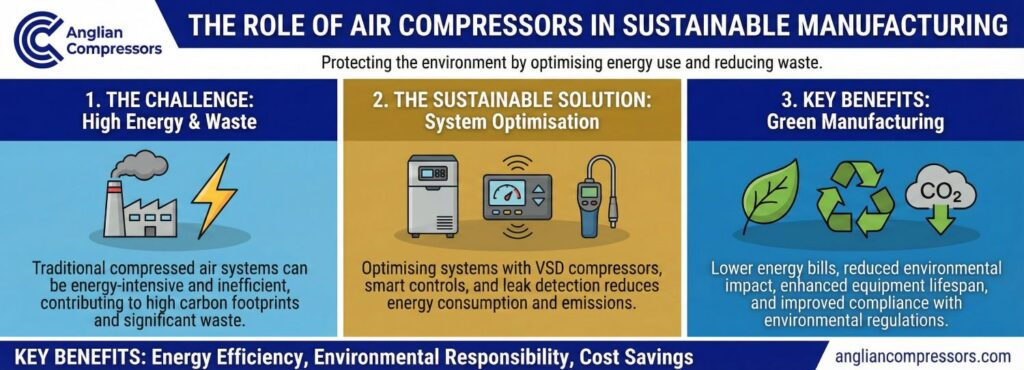

Companies can initially become interested in sustainability in manufacturing as a green initiative. However, the role of air compressors in sustainable manufacturing is crucial to increasing air system productivity while improving efficient energy use.

Air compressors are essentially pieces of equipment for many industries. Producers in pharmaceuticals, food and beverages, chemicals, automotive workshops, dental clinics, and other healthcare providers are all prominent consumers of compressed air.

By adopting eco-friendly air compression systems, energy waste is reduced, and carbon emissions are cut substantially.

In this blog post, we examine the role of compressed air systems in sustainable manufacturing.

Energy Efficiency in Air Compression

Manufacturers often consume more than 10 per cent of industrial energy to produce compressed air. Energy efficiency efforts pay dividends, particularly as up to 80 per cent of an air compressor’s total ownership cost is the energy expenditure over its lifespan.

When constant air production is not required – or an air tank can store excess production – a variable speed drive (VSD) is more energy efficient. It adjusts output based on current demand, reducing the total energy required.

Suitable for sensitive environments and needed in healthcare and food production, oil-free compressors lessen potential oil contamination concerns.

Waste heat recovery systems – built into a new compressor or as an add-on to an existing air system – capture heat. The heat is then repurposed for WCs and other facilities, and hot water is supplied to heating systems. This substantially reduces heating-related energy bills.

Smart monitoring systems notice operational inefficiencies, enact optimisations, recommend maintenance fixes, and reduce downtime.

Reducing Environmental Impact

Efforts to reduce the environmental impact are important to support green initiatives and protect the planet.

Newer air compressors consume less energy, resulting in fewer carbon emissions. No so-called ‘efficiency updates’ to ageing compressor equipment offer the same outcome.

Checking for and resolving air leaks is important. These either emanate from the machinery or the air distribution system. Up to 30 per cent of produced compressed air is lost to these leaks, requiring additional air production to compensate. Therefore, checking for and eliminating leaks via an air audit is worth consideration.

Ambient air quality varies depending on the location, local airborne contaminants, seasonality, and other factors. An advanced filtration system is necessary to screen for damaging contaminants before they affect air systems, pneumatic equipment, or product quality on a production line.

Air systems benefit from using eco-friendly lubricants and materials. They are designed not to harm the environment while still assisting in maintaining system performance.

Advanced, regenerative dryer systems help recycle energy and cut waste in air systems.

Worried about the environmental impact of your air system? Discuss your concerns with our knowledgeable staff at Anglian Compressors, a Branch of Atlas Copco Compressors.

Innovations in Sustainable Air Compressor Technology

Air compressor technology continues to innovate, with exciting developments appearing regularly. Below are some encouraging examples:

Two-stage compressors – achieve better efficiency using a two-stage air compression system. They initially compress ambient air and then compress it again, resulting in a higher compression ratio while using less energy.

Remote monitoring and IoT-based diagnostics – monitor air system performance remotely in real time. Access IoT diagnostic tools to benefit from predictive maintenance and reduced downtime.

Utilise renewable energy – harness renewables through compressor system integration. This reduces the dependence on grid-based power produced using fossil fuels.

Air tank storage and production strategies – store excess compressed air in connected air tanks. Manage spikes in demand, optimise for changing usage patterns, and avoid pushing a compressor’s engine too hard.

Eco-friendly machine coatings and applied materials – machinery now uses environmentally friendly coatings and other materials. These help with durability and boost efficiency while not sacrificing any planet-friendly ratings to do so.

Best Practices for Implementing Sustainable Air Compression

Sustainable air compression requires following best practices. Once implemented, these prevent waste, improve performance, reduce energy demand, and cut carbon emissions.

Regular air audits verify system performance relative to benchmark expectations and previous analysis. Air leaks, wear and tear indications, and other potential system inefficiencies are highlighted for rectification.

Correctly sized air systems are best. Otherwise, when pushed to their limits, they damage the long-term viability of the air compressor. Conversely, an air compressor with excess capacity can be wasteful if it is not a variable speed drive model.

Dedicated air leak detection systems discover new leakages between scheduled air audits. This approach maintains system efficiency by resolving leaks sooner.

Staff require training to operate air systems efficiently. With the team trained, air compressors are better managed, and maintenance is delivered in the most energy-efficient manner possible.

Implementing advanced control systems supports time-saving automation. These systems manage air flow rates and alert staff to irregularities to avoid waste and deliver consistent performance.

Need detailed advice on industry best practices? Contact our team at Anglian Compressors, a Branch of Atlas Copco Compressors.

Economic Benefits of Sustainable Air Compressor Use

There are various potential financial benefits to operating air systems sustainably. Below are a few of them:

Better equipment lifespan: controlled operations and timely maintenance reduce potential wear and tear. As a result, the equipment lasts longer.

Reduced operating costs: sustainable air compressors consume less energy than their air output, offering owners substantial cost savings.

Gain a competitive advantage: customers support planet-friendly companies by rewarding them with their business.

Government rebates and other incentives: at certain times, UK businesses can obtain incentives or financial rebates when using more energy-efficient systems. Do not miss out.

Lower maintenance costs and less downtime: predictive, real-time data analytics and constant monitoring tools help to avoid expensive breakdowns. Maintenance is proactively performed based on new indicators rather than a set schedule.

Conclusion

Green manufacturers and operators prefer sustainable air compression technologies. These run more efficiently, lower energy expenses, harness waste heat, and cut carbon emissions.

Current air systems are worth assessing to look for energy-efficient upgrades. These reorient existing systems toward current sustainability goals.

Both economic savings and environmental benefits are available when adopting best practices and deploying the latest energy-efficient technologies.

Talk with an air compressor specialist to review energy-saving solutions. Contact Anglian Compressors, a Branch of Atlas Copco Compressors, to book a consultation.