Should I Buy or Hire an Air Compressor?

Businesses often struggle with whether to prioritise short-term or long-term air compressor usage. How does this factor into capital allocations and cash flow considerations?

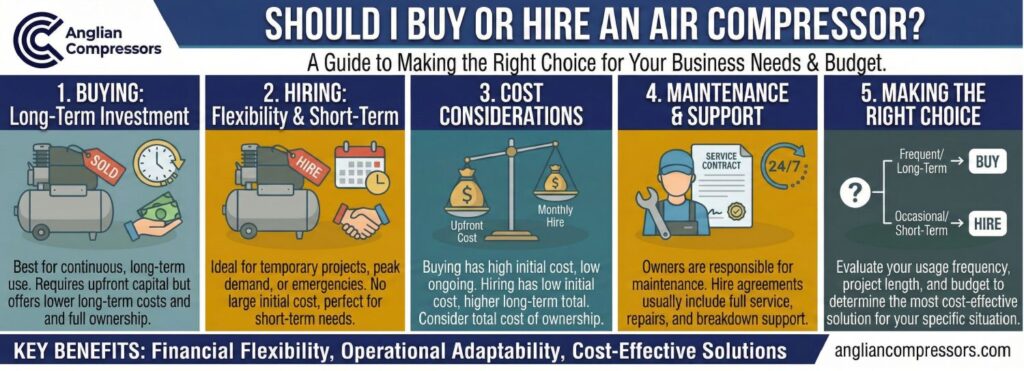

Should I buy or hire an air compressor? It is not always a straightforward decision. A market’s shifting sands, budgetary pressures, and project-based work all contribute to altering current needs and future wants.

Whether to hire or buy an air compressor is a decision based primarily on cost; however, other factors are also relevant. Operational efficiency is certainly one, extra downtime risk is another, and production scalability is also worrisome.

Let us take a closer look at the decision-making process necessary to make the right choice for your business.

Understanding the Key Differences

A decision to buy an air compressor offers purchasers true asset ownership, including control and management of the equipment. Hiring a compressor offers only temporary access to this type of equipment without the sizable capital outlay.

Some rental models include compressor servicing, replacement parts, and emergency support. Contracts vary with rentals, so it pays to check the small print before signing.

Buying an air compressor means long-term responsibility. This includes maintenance, repairs, and ultimately the resale or disposal of the asset.

When Buying an Air Compressor Makes Sense

Compressed air equipment ownership is ideal for year-round operations where businesses require access to substantial quantities of compressed air to operate expensive machinery. Ownership offers increased control and better management of air delivery for sustained operations.

Long-term cost savings can be anticipated throughout a compressor’s lifespan. This is due to the greater efficiencies achieved during operations, improved maintenance, and lower average annual costs.

Systems can be tailored to specific site requirements. A rental company has limitations on the changes that are permissible during installation and operation. These may not be suitable for a larger operator.

The balance sheet records the compressor asset throughout its entire capital depreciation cycle. This represents the asset in the accounts while minimising tax liabilities through annual depreciation over the full ownership period.

Interested in buying a compressed air system? Let our team become your expert guide.

When Hiring an Air Compressor is the Better Option

As a temporary solution, your business may consider hiring a rotary screw or other type of compressor. It may be the right solution to manage seasonal demand spikes, during construction work, or as a test before purchasing the same or a similar type of machine.

Renting an air compressor avoids the upfront investment. This may be sensible for projects under severe budgetary constraints. Short-term needs make it difficult to justify purchasing a compressor unless operational requirements include a custom configuration or specialisation.

It may be worth considering hiring if quick deployment is required. This applies in situations where an existing compressor has broken down or in certain emergencies.

Gaining access to the latest energy-efficient models is sometimes possible. Using a compressor that requires less energy to operate can offset the higher cost of renting. Alternatively, application-specific models are a niche area where hiring is an option.

Cost Comparison: Hire vs Buy

Hiring has the advantage of offering predictable costs. These are either project-based ones or monthly expenses over the hire duration. The absence of unforeseen maintenance costs typically simplifies budgeting. However, every hire contract is different.

If you need regular compressed air, it may be more cost-effective to buy rather than hire. Costs beyond the initial purchase and installation should be considered. These consist of asset depreciation, part replacement, routine maintenance, and repair costs.

Hiring an air system includes compressor delivery and installation. Technical support is usually available, either during office hours or 24/7. The most experienced technicians are likely only available during regular office hours.

Investing in an air system necessitates ongoing expenditure; it is not a one-off purchase. Acquiring spare parts, oil refills, air and oil filters, and cleaning supplies is essential. Furthermore, compliance inspections are required, which will entail some preparation.

Flexibility, Scalability, and Risk Management

It is possible to scale operations up or down by hiring additional equipment. This is hard to achieve through larger capital investments.

Variable project needs and changing environmental conditions may promote hiring temporary equipment that is swapped out based on current needs.

Avoiding large purchases can occasionally reduce risk. Without consulting specialists, it is possible to purchase the wrong kind of compressor or one that is not suitable for future requirements.

Unsure whether purchasing or hiring a compressor makes sense? Talk with our team at Anglian Compressors, a Branch of Atlas Copco Compressors.

Servicing, Support, and Downtime Considerations

Hired compressors typically include breakdown cover, servicing, and rapid replacement of faulty machinery.

Owning a compressed air system requires dedicated servicing contracts, maintenance planning, and allowing for potential downtime. Unless compressed air is stored in cylinders for later use, repair delays can shut down a production line for the day. In the worst case, a replacement compressor could temporarily halt production. However, timely maintenance usually avoids these outcomes.

Monitoring and maintenance may only be included in hire packages for businesses that rent compressors.

Environmental and Compliance Considerations

Newer compressor models are available from rental firms. These are likely to meet noise and emission requirements. They may provide older models that are less clean and cost more to run.

Newer compressors were designed to fulfil UK environmental regulations, function more safely, and provide cleaner air for workers. This is true for both purchasing and renting a compressor.

With older-owned compressors, retrofitting may be required to meet industry regulations. Also, as regulations become more stringent, there may come a time when an ageing model cannot be improved sufficiently to remain in compliance.

Sustainability goals may be supported through the hiring model. This is because multiple operators use the equipment over its life, through short-term hire contracts.

Questions to Ask Before Deciding

Is the compressor needed for a short-term or long-term project?

Hiring can be cost-effective for a few months, but it is usually not cost-effective for longer periods.

Will your workload vary seasonally or remain stable?

Different compressors could potentially be hired based on seasonal demands. However, this mainly applies to portable units that are easier to swap in and out. It may not be a perfect solution otherwise.

How critical is immediate response in the event of a failure?

In the event of a failure, a prompt reaction is essential. Breakdowns are significantly decreased when regular maintenance and repairs are done on-site.

What is your available capital compared to your operational budget?

Due to financial constraints, renting an air compressor may be a viable option for you. The availability of capital affects the range of equipment available for purchase, whether through financing or in-house funds. Another consideration is whether you require a custom configuration that goes beyond what a hire firm can offer.

Conclusion: Matching the Solution to Your Needs

No one-size-fits-all here. In certain circumstances, hiring a compressor meets immediate needs, facilitates testing of compressor models, and reduces capital expenditure. Owning base load units and hiring additional compressors to manage peak demand are optimal.

Purchasing one or more compressors might be the right choice when reliability, control, energy management, and long-term cost efficiency are paramount. Also, do not ignore compliance requirements.

We advise assessing based on the overall cost of ownership and the operational risk that your company faces. Our staff at Anglian Compressors, a Branch of Atlas Copco Compressors, are here to help you if you need assistance with your decision.