Our Quick Guide to Central Air Compressor Controls

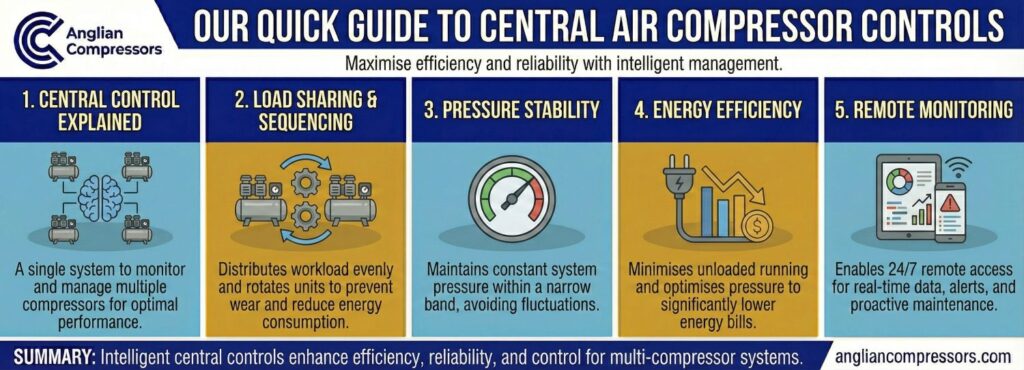

Being able to use compressed air as efficiently as possible is essential for running costs, equipment longevity, and energy usage. Many work environments require multiple air compressors to meet their demands, which is where central control units come in especially useful.

With central control, you can seamlessly manage multiple air compressors using one integrated solution. You will optimise system performance, reduce energy usage, and streamline the maintenance schedule of your entire compressed air network.

This guide explores the intricacies of central air compressor controls and the products available from Atlas Copco: Equalizer 4.0, Equalizer 4.0 PRO, and Optimizer 4.0. We are only a phone call away if you have any questions.

Anglian Compressors, a Branch of Atlas Copco Compressors – a leading manufacturer in the compressed air industry – since 1977, so you can rest assured we know our products inside and out. Contact us today for advice on which central control unit is best for your workplace. Keep reading below to learn more about Atlas Copco’s most popular systems.

Understanding Central Air Compressor Controls

The primary function of central controls is to coordinate, regulate, and monitor multiple compressors, whether you have a few units or an extensive network. Using advanced algorithms and real-time data analysis, central controllers ensure that each compressor operates at its optimal capacity while collectively meeting the demand for compressed air.

Central air compressor controls are highly versatile and can be customised to suit the specific requirements of different industrial operations. From basic tasks such as load and unload sequencing to advanced optimisation algorithms that adjust operating parameters in real-time, these systems empower you to maximise energy efficiency and reduce waste.

The Benefits of Central Air Compressor Controls

Central air compressor controls form the backbone of an efficient and reliable compressor control system. By coordinating multiple units as part of a single air system, these advanced compressor technologies help streamline performance, reduce energy use, and extend the lifespan of your equipment.

- Greater energy efficiency: modern air control systems dynamically adjust compressor output based on real-time demand. By ensuring that no single compressor is overworked and closing the inlet valve when not in use, they significantly reduce unnecessary energy consumption.

- Lower maintenance and longer lifespan: centralised systems distribute workload evenly across compressors, which helps prevent excessive wear. Many also include air compressor monitoring systems that track trending data, helping you identify early signs of failure and schedule servicing before a fault affects the entire system.

- Higher reliability and uptime: if one compressor is turned off or fails, another automatically steps in to keep the air supply consistent. This redundancy is crucial in facilities that rely on compressed air to operate their systems continuously. On-site control through a central interface enables quicker response times and more effective troubleshooting.

- Smarter monitoring and decision making: integration with air compressor monitoring platforms provides visibility across compressor components, air pressure, and energy usage. These systems help maintain performance while giving engineers a clearer understanding of how to fine-tune and improve system reliability.

Investing in a central compressor control system is a smart way to enhance system efficiency, safeguard your equipment, and lower the long-term operating costs of compressed air across your site.

Introducing Atlas Copco’s Equalizer 4.0, Equalizer 4.0 PRO, and Optimizer 4.0

Here is everything you need to know about Atlas Copco’s central controllers. Please contact us if you need assistance determining the best compressor for your needs and work environment.

Equalizer 4.0: The Solid Foundation

The Equalizer 4.0 is the base model in Atlas Copco’s lineup. It features a user-friendly interface and straightforward installation, making it an ideal solution for small to medium-sized systems. It manages and optimises the operation of up to six compressors. Key features include:

- Pressure Band Reduction: By minimising pressure differentials, the Equalizer 4.0 reduces energy consumption to help you save on your bills. With every one-bar reduction in pressure, you can expect up to 7% in energy savings.

- Minimal Unload Time: By efficiently managing the time it takes for compressors to unload excess air, the Equalizer 4.0 can boost your overall operational efficiency.

Equalizer 4.0 PRO: Advanced Control and Flexibility

Building on the capabilities of the Equalizer 4.0, the PRO version introduces advanced features and control capabilities, including the ability to manage up to eight compressors. Key highlights include:

- Advanced Visualisation: With comprehensive data visualisation and trending analysis you can gain valuable insights into the performance of your compressor and piping system facilitating informed decision-making.

- Connectivity Options: Integration with SMARTLINK and other advanced connectivity features enhances flexibility and remote monitoring capabilities.

- Equalisation of Running Hours: By equalising running hours and power usage across multiple compressors, the Equalizer 4.0 PRO ensures uniform wear and tear, prolonging the lifespan of your equipment while reducing maintenance costs.

- Reduced Pressure Band: Like its predecessor, the PRO version has a reduced pressure band allowing you to optimise energy consumption while ensuring your compressed air system remains reliable.

Optimizer 4.0: Unleashing Peak Performance

The Optimizer 4.0 is the pinnacle of Atlas Copco’s central control solutions, designed for large-scale industrial operations. It provides comprehensive performance enhancements and unmatched scalability. Key features include:

- Comprehensive Performance Enhancement: Compared to the Equalizer models, the Optimizer 4.0 model features a wide range of additional functionalities that further enhance compressor performance, reducing the total cost of ownership while minimising emissions.

- Extended Connectivity: Controls up to 30 compressors, 30 dryers, and three AIRnet systems, making it ideal for complex installations.

- Standard Energy Monitoring: Unlike its predecessors, energy monitoring capabilities come standard with the Optimizer 4.0 model providing real-time insights into energy consumption and optimisation opportunities.

- Reduced Load Cycles: By minimising load cycles and optimising flow control, the Optimizer 4.0 model maximises the efficiency of your compressed air system while prolonging the lifespan of your equipment and minimising business downtime.

Choosing the Right Central Controller for Your Needs

Selecting the most suitable central controller depends on your operational requirements, budget, and desired features. While the Equalizer 4.0 is a solid choice for basic control needs, the PRO version has advanced features for those who need greater flexibility and control. For large-scale industrial operations where peak performance and optimised energy usage are essential, the Optimizer 4.0 model is the ultimate solution.

If all your compressed air units are the same size, the Equalizer 4.0 PRO may be the best option for your workplace. This solution seamlessly operates your entire compressed air system, initiating the activation of each compressor in a sequential manner based on a central pressure measurement.

Optimizer 4.0: The ultimate solution for large-scale systems requiring scalable, energy-efficient controls and comprehensive performance trackingBy using detailed insights into the type, size, flow, power, and status of your machines, Optimizer 4.0 can make intelligent decisions to optimise the efficiency and performance of your entire compressed air system.

With the Optimizer 4.0 model, you not only save energy and reduce greenhouse emissions but also extend the lifespan of your equipment while minimising maintenance costs. This could help you bolster your entire operation’s efficiency and profitability.

Order Your Central Control Unit Today

Anglian Compressors has been at the forefront of the UK’s compressed air industry for nearly 50 years and a Branch of Atlas Copco Compressors. We hope this guide has given you all the information you need to invest in the most appropriate central controller for your workplace. If you have any questions or need advice, please do not hesitate to get in touch. One of our experienced technicians will gladly offer personalised and impartial advice.

FAQ

What is a compressor control system, and why is it essential for my air system?

A compressor control system manages the operation of multiple compressors within a compressed air network. By coordinating performance, adjusting output, and closing the inlet valve as needed, it helps maintain pressure levels, reduce energy consumption, and improve the overall system reliability. Control is essential to maintain a consistent and cost-effective air supply.

How do air compressor monitoring systems help reduce downtime?

Air compressor monitoring systems track trending data such as air pressure, temperature, and compressor components in real time. By identifying performance changes early, these systems help you carry out targeted maintenance before faults develop. This proactive approach makes troubleshooting easier and keeps production running smoothly.

Can a single compressor support climate control in large facilities?

A single compressor may not be sufficient to support large-scale operations or climate control systems that rely on compressed air. Modern air systems often utilise multiple advanced compressors, which are managed by a central controller. This allows the system to adjust output efficiently, cool the air supply when needed, and ensure constant airflow without overloading any one unit.