How To Make Your Air Compressor More Efficient

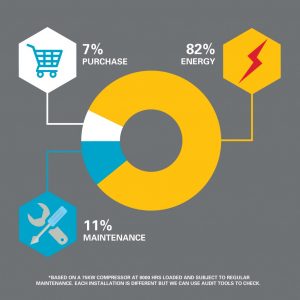

In industrial manufacturing sectors, energy usage is a major line item on company expenses. Depending on the facility, the energy bill can comprise at least one-tenth of all costs, and sometimes considerably more.

System efficiency, both in decreasing energy to operate, and reducing lost energy too, is enormously important. Companies also have goals to run in a more planet-friendly way, so lowering CO2 emissions comes under consideration when choosing plant equipment too.

With industrial and other types of facilities that require compressed air production on-site, making that entire process more efficient is key. Here are 10 areas to examine to see whether one can increase the efficiency of air production.

1. Look at the compressed air system design

Older compressed air systems are often a hidden source of energy waste. Many were installed without future demands in mind, resulting in poor airflow, pressure drops, and increased energy consumption. These issues reduce the efficiency of air compressors and lead to higher energy costs for industrial manufacturers.

The first step to optimising energy efficiency is to assess the entire air compressor system. Obstructions such as undersized pipework, inefficient drainage, or poor layout force the air compressor to use more energy to deliver the air you need. This affects compressor performance and can shorten the lifespan of your equipment.

Using modern compressor controllers or a monitoring control system helps maintain efficient operation by adjusting to compressed air demand. This supports maximum efficiency across your compressed air network without affecting your applications.

Anglian Compressors, a branch of Atlas Copco, can evaluate your compressed air installation and recommend improvements to reduce total energy consumption and CO₂ emissions while improving overall system performance.

2. Lessen unloaded hours

Fixed speed compressors waste energy by needing to be continually running. When they’re unloaded, it can often be compared to running the heating at home with the windows wide open.

Turning off a fixed speed compressor and turning it back on when needed puts wear on the motor. Not to mention that there is also a fixed number of times this can be repeated successfully in a short period too.

Alternatively, a variable speed drive air compressor is designed not to run continuously. Instead, it is turned on to complete a specific activity (producing compressed air volume at a set air pressure) and then can be powered down again, or will power down automatically, when there is no demand. This cuts the machinery running time, so wear and tear is reduced, plus it saves energy too.

Fact Update: Atlas Copco’s VSD+ technology allows for seamless operation by automatically adjusting to the facility’s air demand, ensuring energy usage is reduced by up to 60% in optimal scenarios.

3. Don’t operate at a higher-pressure band, if not needed

Some fixed speed air compressors are set to a higher-pressure level because they’re run using a ‘set it and forget it’ strategy. As stopping and unloading the compressor requires time, some companies will operate at a higher pressure band than they need in most cases.

It’s worth noting that dropping one bar of pressure cuts energy usage by up to 7 percent. Double-check your applications/machinery to verify the minimum air pressure they require to operate well. It may surprise you to learn that the minimum pressure is often lower than how the compressor is currently set.

Reducing pressure by 1 bar can lower energy usage by 7%, as per Atlas Copco’s energy-saving studies. Consider implementing central controllers to fine-tune your pressure settings to actual demand.

4. Don’t waste the heat available from Compressing air

Many air compressors generate heat as part of their operation. This is known as waste heat.

The heat can unnecessarily increase the internal temperature at the facility. Therefore, heat recovery is important. However, it should be recovered and harnessed. Utilise the heat in water systems to reduce energy usage there. Additionally, space heating systems can use it as well.

Doing this requires some adjustments, but it will lower energy costs outside of the air compression room and reduce the carbon emissions of your business too.

Energy Efficiency Note: Heat recovery systems can reclaim up to 90% of the energy used during compression for heating water or spaces.

5. Use a more energy-efficient air compressor

Air compressor technology has seen several significant advancements over the last few years.

The most noteworthy is the switch to variable speed drive (VSD) systems, which allow for shorter runs, and powering down or lowering the energy usage of the compressor, when not in use. A 35% energy saving was initially achieved with first-generation VSD compressors instead of fixed speed technologies.

Furthermore, Atlas Copco, whilst being the originator of this new variable speed technology, has not stopped there. They’ve subsequently released VSD+ compressors with a 50% energy saving, and the latest VSDs range has achieved up to 60% energy reduction.

Fact Verified: Atlas Copco’s GA VSD+ compressors are Class 0 certified, offering oil-free operation while achieving unparalleled energy savings.

6. Get a professional’s opinion with an Air Audit

An Air Audit from Anglian Compressors, a branch of Atlas Copco, will help isolate where inefficiencies reside in your current compressed air systems.

Whether that’s an old or inefficient compressor increasing the energy bill, heat recapturing, or a better design for greater efficiency, we’re here to help.

Recommendation: Conducting an AIRScan from Atlas Copco provides a comprehensive analysis of your air system’s energy profile and leak detection capabilities.

7. Don’t forget the maintenance

Regular maintenance is vital to ensure that the compressor operates at peak efficiency. Neglecting simple tasks, such as replacing filters or checking the pressure settings of the compressor, can lead to energy losses, reduced performance, and higher running costs.

A tailored service plan enhances air compressor energy efficiency, minimises energy waste, and helps prolong the lifespan of your equipment. It also ensures stable pressure, clean airflow, and fewer breakdowns.

Utilising smart compressor control and monitoring tools enables proactive maintenance, helping to prevent costs associated with wasted energy and ensuring your system remains highly efficient. At Anglian Compressors, a branch of Atlas Copco, we support businesses with efficient air compressor servicing that improves energy efficiency and delivers long-term savings.

8. Avoid compressor contaminants

With poor nearby air quality, particulates can get inside the compressor and potentially the motor too. Even the very best filters aren’t perfect at removing contaminants, and can get clogged up before being replaced.

Also, depending on the facility, moisture might be an issue. Additionally, with oil-filled compressors, too little or excess lubrication causes a variety of issues too.

9. Internal pressure drops

An overworked air compressor, or one running at the maximum pressure setting, can experience internal pressure drops. This can result in an overworked compressor trying to compensate for this, and failing to do so.

A poorly designed pipe system may be at fault. Unclean filters that haven’t been changed frequently enough, moisture reaching the internal machinery, or a longer air intake transit passage can be contributing factors.

10. Reduce air leaks

Older air compressors that have “seen better days” are frequently responsible for air leakage. While the leakage opening might seem minuscule, just a couple of millimetres for example, the lost air and subsequent cost can be considerable.

Running the compressor and testing for leaks is the best approach to finding and fixing air leaks.

The most efficient approach to verifying whether your current air compression systems are inefficient is to get an air audit. An air audit from Anglian Compressors, a branch of Atlas Copco, will confirm how much more efficient the compressed air system could become, and whether a replacement air compressor is the answer, or something with a quick fix.

Improvement: SMARTLINK monitoring systems should be used to identify and address leakages effectively. These solutions provide real-time updates, enhancing system reliability.

Do you need a team of professionals to help make your Compressed Air more efficient? If so, get in touch with Anglian Compressors, a branch of Atlas Copco.

FAQ

What are the best ways to make a compressor installation more energy efficient?

Improving the layout of your compressed air system, selecting the right size air compressor, and using a VSD compressor could all help reduce the energy to overcome system demand. Best practice tips will help optimise performance and deliver compressed air energy savings across your site.

Why does choosing the wrong size air compressor matter?

A compressor not based solely on your actual air demand may lead to increased wear, wasted energy, and unnecessary running costs. Choosing the wrong size air compressor often results in higher total energy costs for industrial users and may prevent the system from reaching peak efficiency.

Can waste heat from air compressors be reused to lower energy consumption?

Yes. Many industrial air systems now include energy recovery features that repurpose waste heat from air compressors. This heat can be redirected to support water or space heating, offering substantial energy savings and enhancing the overall efficiency of your compressed air system.