How to Extend the Lifetime of Your Air Compressor

An industrial air compressor is a major investment. Its operational lifetime is not fixed, but a direct result of its environment, maintenance, and daily use. Extending your compressors lifetime reduces ownership costs, minimises production downtime, and lowers your energy bills. This guide from Anglian Compressors, an Atlas Copco Premier Distributor, provides practical strategies to maximise the lifespan and efficiency of your compressed air system.

Start with the Right Environment to Extend Compressor Lifetime

A compressor’s service life is impacted from day one, and the room where it operates is a critical part of the system.

Why Your Compressor Room Matters

Your compressor room needs two things: cool, clean intake air and a way to remove heat. Poorly designed spaces force the machine to work harder, putting constant strain on all components and accelerating wear.

Prevent Overheating with Good Ventilation

Heat is the main enemy of an air compressor. High ambient temperatures cause overheating and shutdowns, with a 10°C increase above the design threshold halving the life of compressor oil. Overheating also causes varnish and sludge, which block coolers and starve bearings of lubrication.

Protect Your Compressor with Clean Intake Air

The air inlet is the “lungs” of your compressor; it breathes in dust, debris, and contaminants which are then concentrated. This material clogs filters, fouls coolers, and adds abrasive particles which grind away at internal components. The intake should be placed in a clean area free of dust and exhaust fumes to minimise the contaminants introduced to your system.

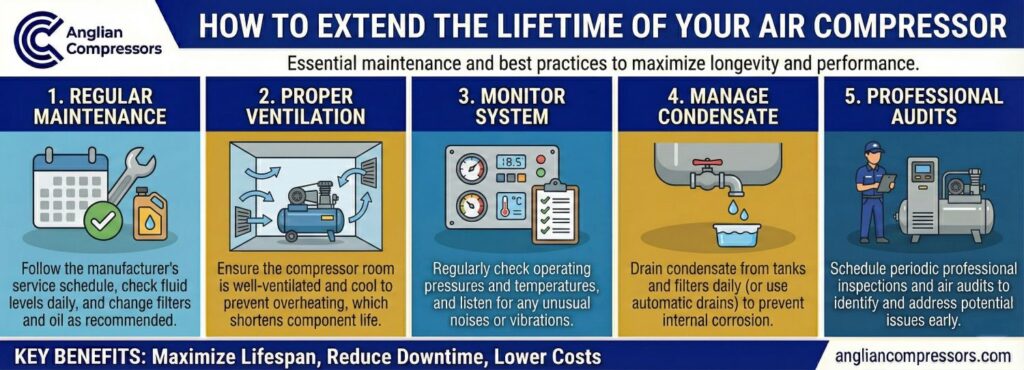

Build a Proactive Maintenance Plan

The best way to maximise the useful life of your equipment is to shift from reactive repairs to a proactive schedule. Preventive maintenance can prevent minor problems from turning into expensive breakdowns later on.

Key Operator Checks for Daily Upkeep

Your first line of defence against damage and shutdowns is regular on-site inspection. These simple checks are the basis of all essential maintenance activities:

- Check Oil Levels: Prevents failure caused by oil starvation.

- Drain Condensate: Daily draining stops internal corrosion.

- Monitor Vitals: Check temperatures and pressures for early warnings.

- Inspect for Leaks: Look for any signs of air or oil leaks.

- Keep it Clean: Cleaning vents and coolers weekly ensures proper airflow.

The Value of Professional Servicing

Servicing is to be carried out in accordance with the manufacturer’s service schedule. This includes utilising genuine OEM parts for all replacements, ensuring peak performance and keeping your warranty intact. A full servicing package from a dedicated provider such as Anglian Compressors, a Branch of Atlas Copco Compressors, means regular, expert servicing.

Need assistance with a maintenance schedule? Check out our tailored servicing packages.

Protect Your Compressor’s Critical Components

Understanding the key components in your air compressor will show you why a holistic maintenance approach is vital for a long compressor lifetime.

Maintain Your Filtration System

The impact of air compressor filtration is significant. Clogged filters create pressure drops, forcing your compressor to use more energy. A 2 PSI drop alone can increase energy use by 1%, and also generates more heat.

Use the Right Lubricants

Oil is used in a rotary screw compressors to lubricate, cool, and seal. It is critical that you are using the correct compressor oil, as using the wrong oil type can lead to premature wear and failure.

Reduce Wear and Save Energy to Extend Compressor Lifetime

How your system is operated directly impacts its lifespan, and reducing your compressor’s workload is a form of continuous, passive maintenance.

Find and Fix Costly Air Leaks

Air leaks can waste up to 30% of your total air production while also forcing your compressor to run longer, accelerating wear. Anglian Compressors, a Branch of Atlas Copco Compressors, provides professional ultrasonic leak detection surveys to find and fix these leaks.

Optimise Your System Pressure

Many systems run at a higher pressure than needed. For every 1 bar (14.5 PSI) of pressure reduction, you can cut your energy use by 7%, reducing strain on the machine. An energy audit can reveal significant savings; book yours with our team.

Match Air Supply to Demand with VSD⁺

Fixed-speed rotary screw compressors are inefficient for use with fluctuating air demand. Atlas Copco’s Variable Speed Drive (VSD⁺) technology solves this problem by adjusting motor speed to match real-time demand, cutting your energy use by up to 60% and reducing wear.

Upgrade Your Pipework with AIRnet

Outdated pipework creates pressure drops, but modern systems like Atlas Copco’s AIRnet provide a smooth, corrosion-free path for compressed air and are easily scalable for your future needs.

Recover and Reuse Waste Heat

Up to 94% of a compressor’s energy is converted into waste heat. A heat recovery system can capture this unutilised energy to heat water or spaces, turning a cost into a resource.

Use Predictive Technology to Prevent Failures

Modern technology helps shift maintenance from a fixed schedule to a predictive model.

Monitor Compressor Health in Real Time with SMARTLINK

Remote monitoring systems like Atlas Copco’s SMARTLINK provide you with 24/7 data on your compressor’s health. It sends alerts before a breakdown occurs, allowing for proactive intervention.

Want to see how SMARTLINK can improve your uptime? Speak to our experts.

Advanced Diagnostics for Early Warnings

As part of Anglian’s service plans, predictive tools are used to detect failures before they happen. Oil analysis acts like a “blood test” for your machine, while vibration monitoring and thermal imaging spot mechanical and electrical faults early.

Stay Compliant with UK Regulations

Proper maintenance is a legal requirement in the UK.a

Understand Your Legal Duties (PUWER, PSSR)

PUWER 1998 requires employers to maintain their equipment. Most systems also fall under PSSR 2000, which requires a Written Scheme of Examination, and failure to comply can lead to HSE fines and production shutdowns.

Manage Condensate Disposal Correctly

Oily condensate from a compressor is controlled waste which is illegal to discharge it into a sewer without treatment from an oil/water separator.

Meet ESOS Goals with Professional Audits

The Energy Savings Opportunity Scheme (ESOS) mandates energy audits for large organisations. Anglian’s ISO 11011-compliant audits will help you meet these requirements.

Why Anglian and Atlas Copco Offer Superior Lifetime Value

A long-term approach focuses on total cost, not just purchase price. Atlas Copco leads in efficiency and predictive maintenance, maximising your oil-free compressor lifetime as well as lubricated models.

| Feature | Atlas Copco | Kaeser | Ingersoll Rand |

| VSD Technology | VSD⁺ with iPM motors | SFC Series | Nirvana |

| Oil-Free Certification | ISO 8573-1 Class 0 | Class 1+ | Class 0 (select) |

| Remote Monitoring | SMARTLINK + IoT dashboards | Sigma Air Manager | Xe-Series |

| UK Service Network | 24/7 nationwide | Limited | Limited |

| Lifecycle Support | AIRPlan, TotalCare, Extended Warranty+ | Available | Limited |

This technical leadership, along with Anglian’s specialist local support, results in real value added. It’s all about a holistic approach. Eventually, every compressor reaches an age where you must decide whether to repair or replace it. By following this guide, you can make your compressed air system a dependable, efficient, and durable asset.

Take the Next Step to a Longer Compressor Lifetime

To implement these strategies and maximise your compressor’s lifespan, connect with our team.

- Book a free energy audit to identify savings opportunities.

- Explore our preventive maintenance packages for total peace of mind.

- Speak with an expert about your specific challenges.