Guide to LB10-40 Air & Nitrogen Booster

When it comes to compressed air systems in busy industrial settings, striking the perfect balance between efficiency, reliability, and performance is crucial for your business and finances. If you have a relatively low-pressure compressor, you may find your system lacks the power to handle certain tasks.

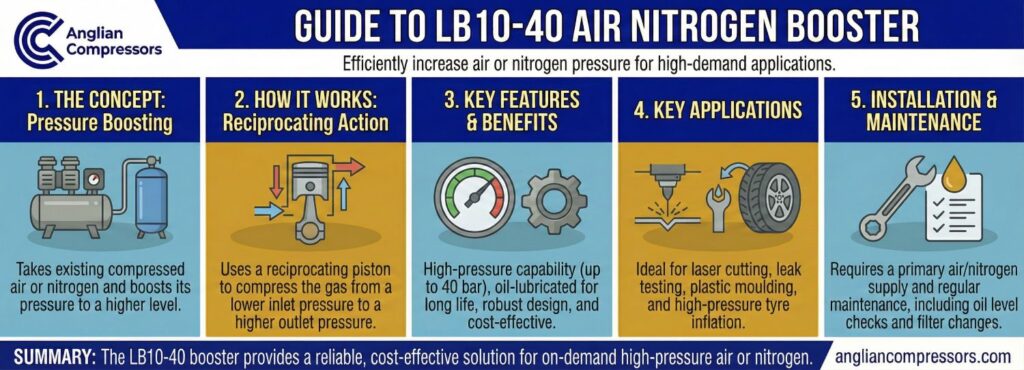

Enter the LB10-40 Air & Nitrogen Booster, a single-stage oil-lubricated piston compressor designed to elevate your medium-pressure applications to new heights. With this booster, you can increase the pressure of your current compressed air system without having to replace it with something larger, more powerful, and more challenging to maintain.

An air and nitrogen booster like the LB10-40 can help you take on more demanding tasks while streamlining your operations and energy usage. But how do boosters work? And, is the LB10-40 Air & Nitrogen Booster the best option for you?

We will explain what makes this compressor an excellent choice for industries ranging from manufacturing to petrochemicals. We are only a phone call away if you need advice based on your unique needs.

At Anglian Compressors, we have been supplying, installing, servicing, and repairing air compressors and accessories for nearly 50 years and a Branch of Atlas Copco Compressors. Call us today to find out how a booster for your air compressor can work wonders for your business and finances. Keep reading below to learn more about boosters and the specifics of the LB10-40.

Understanding Boosters

Boosters like the LB10-40 increase already compressed air or gas to higher pressures of up to 1000 bar, making them perfect for a range of specialised applications in diverse industrial settings. By amplifying the pressure produced by standard air compressors, boosters play a vital role in meeting the demands of high-pressure industrial operations.

When it comes down to it, the LB10-40 Air & Nitrogen Booster is more than just a handy item of equipment; it empowers you to maximise efficiency, reliability, and performance in your workplace. Whether it is industrial cleaning, laser cutting, bottle blowing, or PET moulding, the LB10-40 will ensure that your compressed air system can carry out its tasks efficiently and reliably.

Factors to Consider When Browsing Boosters

If you are new to the world of compressed air, narrowing down your options from the vast number of boosters available can be daunting. Here are five factors you should keep in mind when searching for the most suitable nitrogen and air booster for your high-pressure application:

- Cost: While the initial investment is an important consideration, you need to consider long-term energy consumption to calculate your ongoing running costs and potential savings. (lifetime running costs)

- Efficiency: Look for boosters with energy-saving features such as an advanced IE3 motor and a single-stage design to keep your operating costs to a minimum.

- Continuous Duty: You might want to choose a booster for your compressor that can run 100% of the time without requiring frequent cool-down periods. That way, you can look forward to uninterrupted productivity.

- Reliability: Choosing a solution with quality components and a robust design can help ensure minimal downtime. With the LB10-40 Air & Nitrogen Booster, you can rest assured that downtime will rarely – if ever – be an issue.

- Noise Levels: Low noise emissions enable flexible installation options and cost savings on high-pressure piping.

So, now you know what to look for when searching for an air and nitrogen booster, let us explore why and how the LB10-40 ticks all the boxes in most industrial settings.

Unveiling the LB10-40: a Closer Look

At its core, the LB10-40 Air & Nitrogen Booster is a versatile, high-performing unit, seamlessly combining industry-leading efficiency with unmatched flexibility. This air-cooled, single-stage, oil-lubricated piston booster compressor caters to medium-pressure needs across a spectrum of applications, representing the pinnacle of reliability and performance. Moreover, the LB10-40 can operate continuously, virtually eliminating business downtime.

Technical Specifications at a Glance

Before we delve deeper, let us take a quick look at the key technical specifications that set the LB10-40 apart from much of the competition:

- Working Pressure: 15 bar(a) – 40 bar(a)

- Capacity FAD: 50 m³/h – 500 m³/h

- Installed Motor Power: 7.5 kW – 30 kW

- Capacity FAD l/s: 28.5 l/s – 124.8 l/s

Now that we have laid the groundwork, we can explore what makes the LB10-40 a standout choice for your industrial needs.

Smart, Sustainable, and Flexible

In the realm of industrial air and nitrogen applications, higher pressures often translate to enhanced performance. The LB10-40 acts as a reliable ally, seamlessly integrating into your existing setup to deliver the extra pressure you need to optimise the performance of your compressed air system.

Equipped with the Elektronikon® Touch controller, the LB10-40 streamlines operations by integrating multiple compressor units into one manageable system. Features such as an IE3 motor, low current start-up mechanism, and a wide inlet and outlet pressure range allow it to prioritize sustainability without compromising performance.

Craftsmanship Beyond Compare: 100% Atlas Copco Compressor Block

When it comes to reliability and efficiency, the LB10-40’s compressor block sets a new standard. Designed entirely in-house by Atlas Copco, a revered figure in the air compression industry, every component is highly resistant to wear and tear.

From it’s innovative oil lubrication system to it’s efficient cooling mechanisms, each detail is meticulously engineered with supreme reliability and next-level efficiency in mind. With advanced piston technology, including an oil breathing system and corrosion-resistant steel valve plates, the LB10-40 is a testament to Atlas Copco’s expertise in medium-pressure applications.

The LB10-40’s compressor block is a hallmark of quality, crafted entirely in-house by Atlas Copco, a leader in air compression technology. Every component, from the oil breathing system to the corrosion-resistant valve plates, is engineered for supreme reliability and efficiency.

Ease of Use: Plug & Play Simplicity

As a Plug & Play system, the LB10-40 simplifies installation, monitoring, and maintenance. The Elektronikon® Touch controller ensures constant monitoring of pressure, temperature, and oil levels to proactively prevent potential issues. Features such as automated pressure band settings and Smartlink integration allow for remote system management and optimisation.

Learn More about the LB10-40 Air & Nitrogen Booster

With the LB10-40 Air & Nitrogen Booster, industrial operators can elevate performance, reduce costs, and extend the life of their existing systems. Its intelligent design and energy-efficient components, such as the IE3 motor, deliver high-pressure results without excessive energy consumption.

Anglian Compressors, a Branch of Atlas Copco Compressors, proudly supplies the most advanced compressed air systems and boosters to clients across a wide range of industries throughout the UK. And because we are a premier distributor for Atlas Copco, you can rest assured we know our solutions and the industries we serve inside and out. Call us today with any queries and we will gladly provide personalised advice.