Energy Recovery for Air Compressors

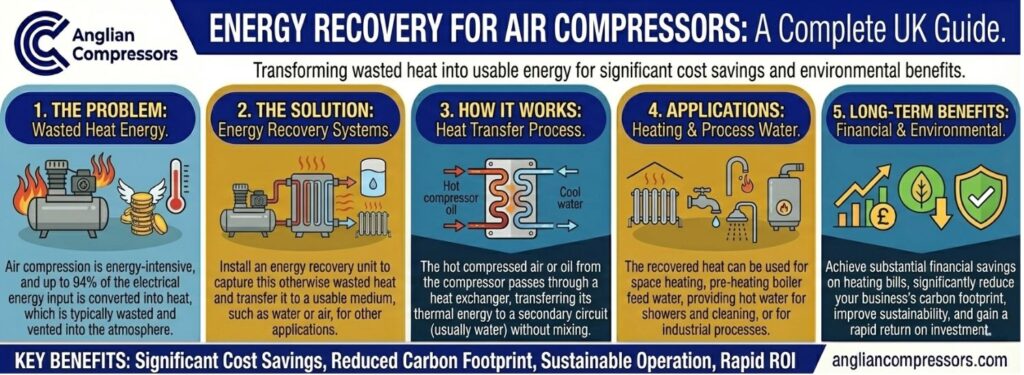

Compressed air systems are major energy consumers, making them an ideal focus for energy-saving efforts. By harnessing the excess heat generated by these systems through heat recovery, businesses can tap into a valuable source of energy conservation.

In this article, we’ll look at all the potential energy savings, seasonal factors, and how modern air compressors incorporate heat recovery in their design.

By the end, you’ll understand how heat recovery reduces energy costs, lowers CO2 emissions, and improves operational sustainability.

Understanding Energy Recovery for Air Compressors

Compressed air systems generate significant heat as a byproduct of their operation. In fact, up to 94% of the energy used in compressing air is converted into heat.

While the energy used to compress the air cannot be directly recovered, the excess heat generated can be harnessed. This is the core idea behind air compressors’ energy recovery or heat recovery systems. Businesses can significantly cut energy costs and reduce their carbon footprint by repurposing this otherwise wasted heat.

How Heat and Air Compressors Are Intertwined

Why is heat generated at all?

Compressed air systems compress air into a smaller volume, which produces compression heat as a natural byproduct. The compressed air must then be cooled, and the extracted heat – commonly called waste heat – is often expelled.

For example, oil-free compressors expel clean, particle-free hot air that can safely be reused, reducing the need for additional cooling measures. Systems with water cooling may also recover this energy by capturing and utilising the heat in industrial processes.

Benefits of Energy Recovery

Energy recovery offers a multitude of benefits that go beyond simply reducing your energy bills. It’s a smart investment that positively impacts your bottom line, the environment, and the longevity of your equipment.

Significant Cost Savings: By harnessing the waste heat generated by your air compressor, you can significantly reduce your reliance on traditional heating and cooling systems. This translates to lower energy consumption and substantial cost savings over time.

Environmental Responsibility: As a business owner, you have a responsibility to minimise your environmental impact. Energy recovery is a powerful tool in this effort. By utilising waste heat, you’ll decrease your reliance on fossil fuels, leading to a significant reduction in greenhouse gas emissions. This not only benefits the planet but also helps your company comply with increasingly stringent environmental regulations.

Extended Equipment Lifespan: Energy recovery can also extend the lifespan of your air compressor. By reducing the thermal stress on the system, you can minimise wear and tear, prevent breakdowns, and avoid costly repairs. This means your compressor will operate more efficiently and reliably for years to come.

With the right implementation, energy recovery systems can deliver long-term savings and improve operational efficiency.

Overall, energy recovery is a win-win solution. It’s a smart investment that pays for itself through energy savings, reduces your environmental footprint, and ensures the longevity of your valuable equipment.

Implementation Strategies for Energy Recovery

Every business is unique, and so are its energy needs. The implementation steps below are just a rough guide on how to approach adding energy recovery to your plant. But if you want something more specific and tailored-fit, contact us!

- Assess Your Current System: Begin by evaluating your existing compressed air system. Analyze your energy consumption data to identify peak usage times and potential areas for improvement. Determine the amount of waste heat generated by your compressor and consider the potential applications for this recovered energy within your facility.

- Explore Energy Recovery Options: Research the different types of energy recovery systems available, such as those that capture heat from discharged air or cooling water. Consider factors like your compressor’s size, type, and the intended use of the recovered heat.

- Calculate Potential Savings: Use online tools or consult with energy efficiency experts to estimate the potential energy and cost savings you could achieve by implementing energy recovery. This will help you determine the return on investment (ROI) and justify the investment.

- Choose the Right System: Select an energy recovery system that aligns with your specific needs and budget. Consider factors like installation costs, maintenance requirements, and the expected lifespan of the system.

- Partner with Experts: For a seamless transition, consider partnering with professionals who specialise in energy recovery systems. They can provide guidance on system selection, installation, and ongoing maintenance to ensure optimal performance and maximum savings.

At Anglian Compressors, a Branch of Atlas Copco Compressors, we offer tailored solutions, from energy audits to turnkey heat recovery systems, ensuring maximum savings and efficiency.

What is the Potential Level of Energy Saved?

Up to 94% of the energy used in air compression can be recovered as heat. This heat can be redirected for:

- Space heating: Expelled hot air can warm factory floors or offices during colder months.

- Water heating: Waste heat can supply hot water for showers, sinks, and industrial processes, reducing boiler reliance.

These applications reduce overall energy demand and wear on secondary systems like HVAC or plumbing, further lowering operational costs.

Do All Air Compressors Have Heat Recovery Potential?

Most modern air compressors are designed with heat recovery in mind, particularly screw compressors and oil-free compressors. Retrofitting heat recovery equipment is an option for older systems, enabling businesses to unlock energy savings without purchasing new compressors.

Compressor Plant Location vs. Utilisation Location

One limitation of heat recovery systems is the need to be as close as possible to where excess heat is to be used. Therefore, when planning to use hot water for bathrooms and showers, the compressor plant room, or installation location, benefits from being closer to where these are situated.

Similarly, to use space heating in the factory, it’s helpful if the ductwork from the compressor plant room to where workers are situated isn’t extensive. Otherwise, the ductwork installation cost is higher, and some heat will be lost along the route.

Let Anglian Compressors, a Branch of Atlas Copco Compressors, Reduce Your Energy Bill

Anglian Compressors, a Branch of Atlas Copco Compressors, specialises in designing and installing systems that maximise heat recovery. With many systems paying for themselves within 3–4 years, this investment ensures long-term savings and environmental benefits.

Depending on the implemented system, the cost of heat recovery equipment is often recovered within 3-4 years. This provides true savings to businesses for years to come. Get in touch.