Compressed Air Condensate and Its Disposal

All compressor installations generate condensate. This is not just water, but a mixture of oil, particulates, and other contaminants created during the air compression process. The condensate contains waste oil and is classified as hazardous waste under UK law.

Incorrect disposal can be detrimental to the environment. Discharging untreated compressed air condensate to public surface water drains is illegal and can result in significant penalties.

In this article, we examine how condensate forms, the importance of proper condensate management, and the safe disposal of condensate in accordance with current UK regulations.

Moisture in the Air

Compressors release condensate near the unit itself. This might look like H2O, but it’s not. It is water, combined with tiny parts of oil mixed in, and some particulate matter that’s too small for the human eye to see. This mixture makes proper disposal both essential and legally regulated. This interesting concoction results from the compressor’s operation.

The air that is pulled in through and past the inlet valve into the compressor will naturally contain moisture from the air. We typically might refer to this as humidity, but the type and quality of ambient air near the inlet have an impact on the moisture levels after the compressor has completed its work.

Compressed air can happily contain water within it. That is, up to a certain point. This is referred to as the pressure dew point. Air will have a pressure dew point, but so do various gasses as well. They will each be unique.

The pressure dew point marks the point at which air cannot retain moisture and begins to form condensation. Properly controlling this is essential for efficient compressor operation.

This point is the stage where water cannot be held within the air or gas, and it will become condensation. Alternatively, it will become a liquid, when there’s too much vapour, and it’s impossible for it to remain in its current state.

We admit it can get complicated here. However, it is referred to as compressibility. If you think of a sponge, it can hold water. But, there is a limit to how much water the sponge can contain beyond its natural weight. After that, it begins to leak water on the bathroom floor. And… so it is for air compressors, too.

For example, setting a compressor to 7 bar of pressure condenses air down to seven eights of its original volume. Because the same air now takes up less space, it has reduced its water-holding capability by the same amount. Therefore, when compressing moist air, it will compress down successfully, but water will remain after the condensing process.

As a practical example of what we mean, about 84-86 litres of water result when a 100-kilowatt air compressor pulls in air at 20 degrees Centigrade, with roughly 60% humidity levels and runs for roughly eight hours.

The more hot and humid air, such as in a tropical environment, the more compressor condensate is generated through the air condensing process. Indeed, in a highly humid environment, it is likely that a compressor could produce several hundred litres of water daily. Therefore, knowing this, arranging for it’s legal and safe collection is important.

Issues Caused by Too Much Moisture

Too much moisture in your compressed air supply can have serious consequences. Inside the system, water content in compressed air can corrode internal components, damage valves, and reduce the efficiency of filters and dryers. This results in increased energy consumption, unplanned downtime, and costly repairs.

As the condensate travels through your system, it affects downstream equipment and processes. In industries where quality air is critical, such as food production or electronics, the presence of moisture or oil can compromise output or pose safety risks.

Condensate that collects in receiver tanks or at condensate drainage points can become a hazard if not managed properly. Allowing it to flow directly from a drain onto the ground or into a stormwater system is not only poor practice, but also illegal. UK law classifies condensate from compressed air as hazardous, and improper disposal can be detrimental to both the environment and your reputation as a responsible operator.

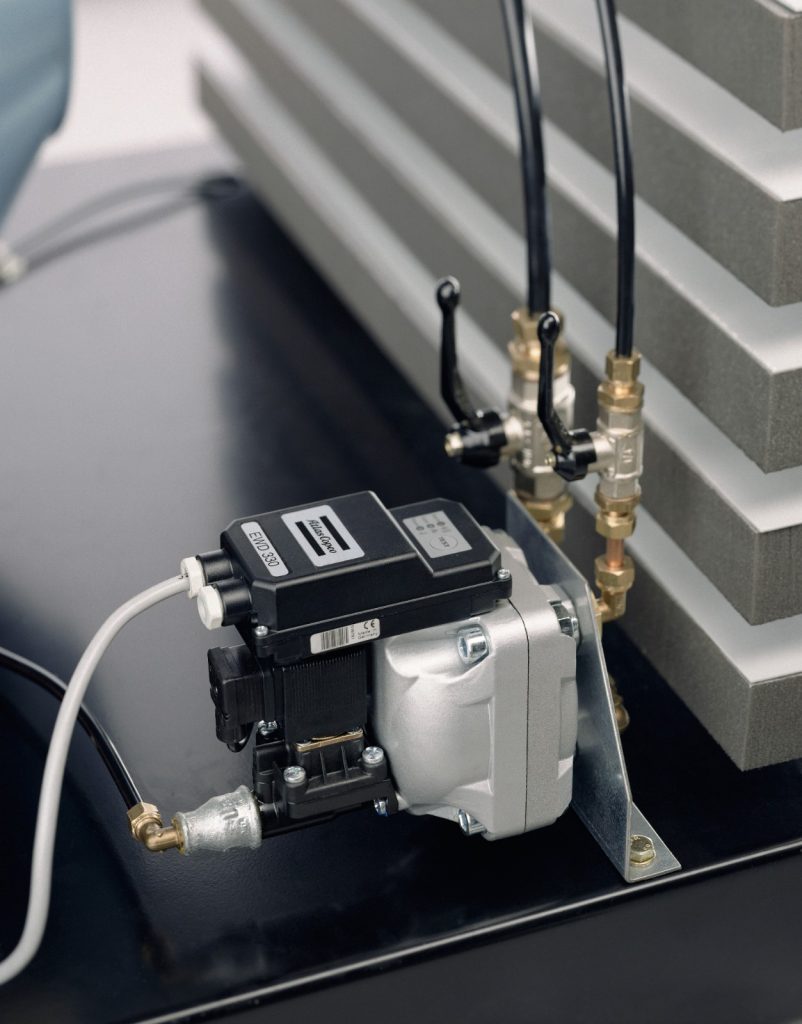

Effective compressor condensate management includes using aftercoolers, separators, properly sized drain valves, and oil-water separators. These systems ensure that condensate is treated and disposed of responsibly, in line with guidance from the British Compressed Air Society. New installations should have condensate drainage and separation systems as standard to ensure compliance and efficiency.

Managing Condensate to Stay Within UK Law

Environmental awareness affects everyone, and businesses are no exception either. Existing laws in the UK are robust, but newer, tougher ones come on the law books regularly.

Companies that use compressed air equipment, which relies on oil either injected or added through another process, need to make themselves aware of the correct way to dispose of condensate to stay within the law. Damage assessment costs and fines for improper disposal can occur when not following the rules.

Improper disposal of oil-laden condensate can lead to significant fines and environmental damage, harming both compliance and reputation.

Also, with the ease of sharing negative news in the media, companies need to stay ahead of any PR issues by avoiding making such mistakes, rather than acting now and apologising later.

An initial review of the existing compressors by an appropriate, knowledgeable manager is never a bad idea. This should take in the state of the filters, wet air receivers, dryers, condensate drains in the rear, etc.

For oil-based compressors, it’s necessary for what’s being expelled to run through a process to remove any oil from the condensate. An oil/water separator is a useful inclusion and should be added if it’s not already present. These often have multiple processes to gradually remove all oil from the condensate, to make it safe to dispose of.

Installing an oil/water separator ensures compliance, with advanced models able to reduce oil contaminants to below 0.01 microns, making discharge safe and legal.

A discharge notice from the local water authority is necessary for permission to dispose of condensate that’s been properly processed. Once it’s clear of oil, the water needs to be directed to the foul water drainage system. Using storm drains or rainwater systems for discharge is strictly prohibited under UK law. A storm water drain or a standard rainwater drainage system is incorrect, and should not be used.

When reviewing the current installation, where drain water from the compressor system is either being collected in a plastic tub or is being allowed to leak onto the floor, this needs an immediate resolution to resolve the matter. Also, when no oil/water separator equipment is present, this should be added ASAP.

Lastly, local regulations vary from place to place, site to site. If you operate your business at multiple locations, it’s necessary to verify what permissions are required for discharging water at each location. Collaborating with the Environmental Agency ensures proper compliance across all operational sites.

This might come from a local water authority, or exemptions sought and obtained from the Environmental Agency, where appropriate. This needs to take place before more disposals occur.

Do You Need a Review of Your Installation?

Anglian Compressors, a branch of Atlas Copco, have decades of experience in installing, maintaining, overhauling, and upgrading air compressors. If you’re unsure where your business stands, get in touch, we are happy to help.

Contact us below.

FAQ

What is the correct way to dispose of condensate water from an air compressor?

Condensate water must be treated before disposal, especially if it contains oil or other contaminants. The use of oil-water separators ensures that the condensate is treated responsibly, with contaminants removed prior to final discharge. It is never permitted to discharge untreated compressed air condensate into a foul water drain or surface water system. To remain compliant, a hazardous waste producer or a licensed waste carrier should handle disposal.

Why is incorrect condensate disposal considered detrimental?

Incorrect disposal, such as going straight from a drain onto the ground or into the wrong drainage system, can lead to environmental damage and legal penalties. Condensate from your compressor system installation often includes waste oil and other contaminants, making it a controlled waste. As a waste producer, you are legally responsible for its safe handling, and improper methods can harm your reputation and lead to regulatory breaches.

Do condensate disposal requirements vary across the UK?

Yes. Rules can vary from region to region. While general guidance exists through organisations like the British Compressed Air Society and manufacturers such as Atlas Copco UK, local water authorities may have specific conditions. It is essential to verify what is required for condensate drainage points feeding into each site’s system, especially when operating across multiple locations.