Benefits of on-site nitrogen generation

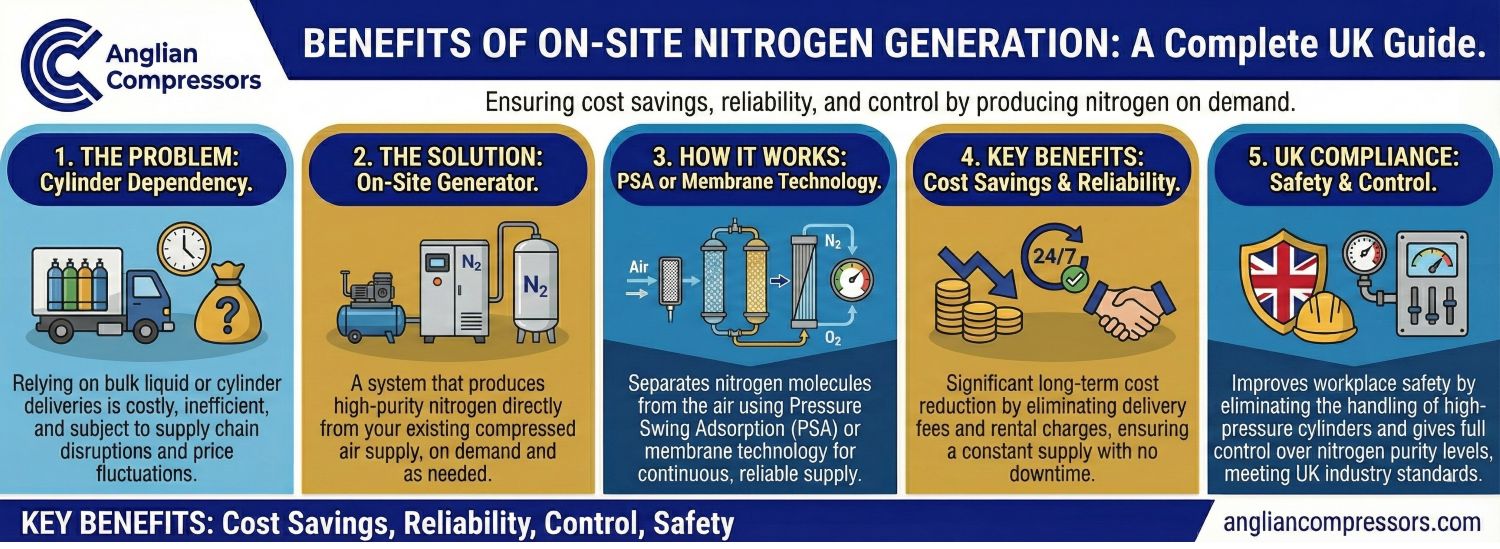

Nitrogen is required for many manufacturing facilities. Generally, this involves having the gas delivered in pressurised bottles at the required purity level or having on-site gas tanks reloaded.

In the past, businesses would store bottled nitrogen and have their whole manufacturing process reliant on prompt gas or liquid nitrogen delivery. Dispatch delays or complications would halt their production. Now, affordable technology has made on-site nitrogen generation possible for businesses that can’t afford not to have nitrogen. Many industries now produce nitrogen, and this trend is only increasing.

At Anglian Compressors, a Branch of Atlas Copco Compressors, we offer an alternative to help you avoid these potential pitfalls. We can help you generate your own nitrogen via an on-site nitrogen skid.

What is On-Site Nitrogen Generation?

An on-site nitrogen generator is a compact unit that lets you produce nitrogen gas on your premises. This integrated package, often called a nitrogen skid, separates nitrogen from the surrounding air directly at your facility. It includes all the key components, such as an air compressor, filtration, and a nitrogen gas generator, designed to operate reliably with minimal input. This alternative method to traditional pressurised cylinder or bulk liquid tank deliveries offers numerous advantages across financial, operational, safety, and environmental domains.

By utilising compressed air, the system separates gases to deliver high-purity nitrogen as needed, eliminating the need for bottled nitrogen or bulk liquid deliveries. This helps eliminate the inconvenience of a delivered nitrogen supply and ensures you always have a reliable source of nitrogen for your operations.

Whether you need a small amount of nitrogen or a continuous flow, these systems are flexible and economical. They are commonly used in many industrial applications where nitrogen quality and availability are critical.

The Inefficiencies of Traditional Nitrogen Supply

When businesses used to get nitrogen from external suppliers, many hassles came with it:

- Locked-in Contracts: When you purchase nitrogen from a vendor, you are usually required to make a long-term commitment. This can be problematic if your nitrogen needs change or if your business experiences fluctuations in demand.

- Delivery Blues: Vendors often have limited delivery schedules, which can mean that you have to wait days or even weeks for a nitrogen delivery. This can disrupt your operations and lead to lost productivity.

- Surprise Price Hikes: The price of gas or liquid nitrogen can fluctuate significantly, and you are at the mercy of your vendor’s pricing policies. This can make it difficult to budget for your nitrogen costs.

- Those Extra Fees: In addition to the cost of the nitrogen itself, you may also have to pay tank rental fees and other hidden costs. These can add up over time and make nitrogen a costly proposition.

- Running on Empty: If you have a sudden spike in total demand for nitrogen gas, you may run out of supply. This can lead to production downtime and other problems.

- Thinking Green: The transportation of liquid nitrogen requires a significant amount of energy, and there is also the environmental impact of boil-off losses.

- Storage: Using valuable storage space in large quantities is expensive and wasteful. Not to mention the regular maintenance of these storage tanks.

In short, onsite nitrogen generation is a more efficient and cost-effective way to obtain pure nitrogen gas.

How On-Site Nitrogen Generation Works:

On-site nitrogen generation systems use compressed air to extract nitrogen directly from the surrounding environment. To understand how nitrogen generators work, it’s important to know the two main technologies. The system connects to your compressed air line and separates nitrogen from oxygen, carbon dioxide, and water vapour using advanced filtration methods. This provides a continuous and reliable nitrogen supply without the need for nitrogen cylinders or bulk liquid nitrogen. The purity level can be adjusted to meet the specific requirements of each process, whether you need 95% or up to 99.9% purity. These systems are commonly used in industry and are designed to produce as much or as little nitrogen as needed, helping your business improve efficiency and reduce costs.

There are two main technologies used:

- Membrane nitrogen generator filters compressed air through fine membrane fibres that allow nitrogen to pass while removing unwanted gases like oxygen and moisture

- Pressure swing adsorption (PSA) nitrogen generators pass compressed air through twin towers filled with carbon molecular sieve, capturing other gases and leaving high-purity nitrogen behind.

This type of gas generation provides a reliable and economical source of nitrogen. It removes the inconvenience of a delivered nitrogen supply, reduces waste, and promotes energy efficiency across various industrial applications.

The Many Benefits of On-site Nitrogen Generation

Adopting onsite nitrogen offers many advantages. Here is a comprehensive overview of the benefits of switching to on-site nitrogen generation:

Financial and Cost Reduction Benefits

A primary driver for adopting on-site nitrogen generation is the significant reduction in operational costs.

- Substantial Cost Savings: On-site generation is the most economical choice and can eliminate up to 90% of nitrogen costs. Generally, generating nitrogen on-site is often around half the cost of purchasing bottled nitrogen.

- Elimination of External Supplier Charges: You eliminate ongoing costs associated with leasing cylinders or tanks, along with variable delivery surcharges and delivery charges.

- Cost Predictability: Without fluctuating delivery price spikes or hidden fees, businesses gain cost predictability and can more accurately control their operating budgets.

- Rapid Return on Investment (ROI): On-site systems generate nitrogen at a much lower cost per cubic metre. The ROI is often realised quickly, typically within 6 to 24 months.

- Zero Waste: Traditional supply methods result in wasted gas from residual pressure in returned cylinders (often 10% or more) or “boil-off” evaporation from liquid tanks. On-site generation avoids this waste because generation enables you to produce only the volume required.

- Avoid Over-Specification: You avoid paying for higher purity or high pressure levels than your application actually requires, a common issue with delivered gas.

Operational Control and Reliability

On-site generation transfers control of the gas supply from a third-party vendor directly to the facility owner.

- Complete Supply Control: Businesses gain complete control over their nitrogen supply, eliminating dependence on third-party deliveries.

- 24/7 Availability and Continuous Supply: Nitrogen is available 24/7. Nitrogen generation systems continuously produce high purity nitrogen on demand, ensuring a continuous supply and minimising the risk of production downtime due to a missed delivery.

- Purity Control: Operators can set the exact nitrogen purity level needed for each job directly on-site. This avoids producing gas at unnecessarily high purity levels, which, in turn, helps reduce energy costs.

- Predictable Production: A continuous and reliable supply allows for predictable production scheduling and maximises the uptime of equipment.

- Scalability: The nitrogen supply can grow with your business, scaling precisely as your business changes.

Safety and Work Environment Improvements

Generating nitrogen on-site significantly improves workplace safety compared to handling high-pressure delivered gas.

- Eliminates High-Pressure Risks: It eliminates the safety risks associated with high-pressure cylinders (which can be pressurised to 200 bar or more) and cryogenic liquids.

- Reduces Handling Injuries: On-site generation removes the potential for worker injuries caused by manually managing the delivery, unloading, and relocation of heavy gas cylinders.

- Avoids Cryogenic Exposure: Staff avoid exposure to high-pressure liquid nitrogen gas, removing the potential for serious burns or other cryogenic injuries.

- Safer Storage: Less gas is stored on-site at any given time, which is inherently safer.

- Minimised Operator Involvement: A typical nitrogen generator requires minimal direct operator involvement once installed.

Environmental and Sustainability Advantages

On-site generation supports corporate sustainability goals by tackling emissions and wasteful energy use.

- Reduced Carbon Footprint: Producing nitrogen at your location means one less delivery truck on the road. That means less gas being released into the atmosphere, to reduce your business’s overall carbon footprint.

- Elimination of Road Transport Emissions: It ends road transport dependency for gas supply, reducing transport-related emissions.

- Greater Energy Efficiency: Modern systems are highly energy-efficient. They avoid the energy waste involved in converting gas to a liquid state for transportation and back again post-delivery.

- Supports Environmental Compliance: Reducing transport-related emissions makes it easier to meet environmental management standards like ISO 14001.

Applications of On-Site Nitrogen

Nitrogen generators are a practical solution that’s been adopted by various industries to meet their nitrogen needs more efficiently. There are tons of applications of nitrogen throughout production processes. Let’s delve into some sectors that are tapping into the benefits of producing nitrogen right where they need it:

- Food and Beverage: Freshness is essential in this industry. Nitrogen generators are used in the food packaging process to keep food fresher for longer. This method, known as modified atmosphere packaging, replaces oxygen in the air (which can make food spoil) with nitrogen, ensuring the product remains in tip-top condition for consumers.

- Electronics Manufacturing: Nitrogen is essential for preventing oxidation in soldering, maintaining clean environments, and ensuring stronger solder joints. Also, nitrogen makes a protective atmosphere for semiconductor manufacturing, as oxygen can damage the delicate materials used in these devices. Having an on-site nitrogen supply means manufacturers can maintain a steady flow without any hitches.

- Metalworking: Nitrogen is used to prevent oxidation and corrosion of metal during welding, cutting, and other metalworking processes. When used for applications like laser cutting, nitrogen leaves a clean, oxide-free edge with no need for secondary finishing. It is also used to create a protective atmosphere for metal fabrication, as oxygen can weaken the metal.

- Pharmaceuticals: Safety and high-purity nitrogen are non-negotiable in the pharmaceutical world. Nitrogen is used to create aseptic environments for the production of pharmaceuticals, as it is an inert gas that will not contaminate the products. It is also used to preserve pharmaceutical products, as it can help to prevent them from degrading.

Industries such as plastics, chemical processing, and offshore drilling also benefit from scalable, energy-efficient nitrogen solutions.

In essence, on-site nitrogen generators provide a tailored solution for industries that require consistent and reliable nitrogen. By generating nitrogen on the spot, these sectors can maintain quality, reduce costs, and ensure they always have the supply they need.

Anglian Compressors, a Branch of Atlas Copco Compressors: On-Site Nitrogen Generation

On-site nitrogen generation is a practical solution for many industries. It can help businesses to improve quality, reduce costs, increase reliability, improve safety, and be environmentally friendly. If you are considering on-site nitrogen for your business, our experts can help your business find the right solution. You can send us a message or contact us!

FAQ

What are the main benefits of using an on-site nitrogen generator system?

On-site systems offer numerous advantages, including the ability to continuously produce high-purity nitrogen from compressed air. They help your business reduce reliance on delivered gas, eliminate supply delays, and cut long-term costs. These systems are designed to meet your total nitrogen gas demand efficiently and reliably.

How does nitrogen generation reduce operational issues?

Nitrogen generation eliminates the inconvenience of waiting for deliveries, handling nitrogen cylinders, or storing bulk liquid nitrogen. By producing nitrogen gas on your premises, you maintain a steady, controlled supply that improves safety, supports uptime, and lowers transport-related emissions.

Where are nitrogen generator systems commonly used?

Nitrogen generators provide solutions for a variety of industrial uses, ranging from food packaging to laser cutting. They are ideal for industries that require high-purity nitrogen from compressed air and eliminate the inconvenience of delivered gas. Installation is simple: just connect the outlet to your existing equipment.