Benefits of On-site Gas Generation

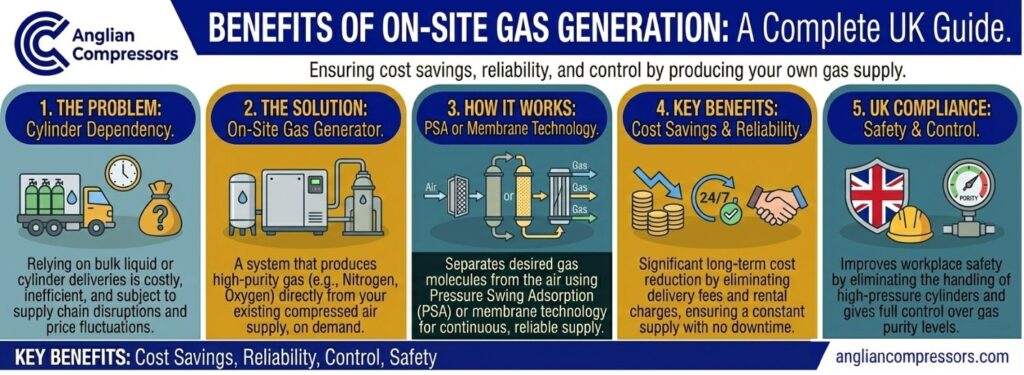

All types of operations depend on gas, from offshore drilling and food production to semiconductor manufacturing and laser cutting. Traditionally, businesses relied on bottled nitrogen or bulk deliveries, but this comes with challenges such as storage management, rising energy prices, and an uncertain gas supply.

On-site gas production offers a more innovative energy solution. Instead of depending on external suppliers, companies can produce a continuous supply through onsite energy systems, improving energy security, reducing energy costs, and shrinking their carbon footprint. Membrane and PSA generators also allow control over purity levels, ensuring the gas meets specific production needs, whether for electronics, food packaging, or industrial applications.

In a changing energy landscape, on-site generation helps businesses take control of their energy supply and stay competitive.

Here are 7 benefits of on-site gas generation.

1. 24/7 Availability

Nitrogen stored on-site prior to use sounds like a good idea. However, one error in the usage calculation and/or a lack of monitoring of on-site supplies and production gets halted. Suddenly, the company runs short of the necessary nitrogen for its operations. A new order and a liquid nitrogen delivery are days away…

Instead, with on-site nitrogen generation, it’s available 24/7. Air is already composed of almost 80% nitrogen. A membrane generator processes ambient air and cleanly extracts the nitrogen from it. Then delivers it at the right purity level. Modern on-site generators often include monitoring systems that track real-time usage, ensuring production continuity.

2. Safer Work Environment

Managing the delivery and unloading process for replacement nitrogen supplies is problematic. Space is needed to store bottles or cylinders, and there’s always the possibility of worker injury. A trapped toe or a foot, or worse, a nitrogen gas cylinder falling onto someone, often leads to injuries.

Before transportation, nitrogen gas must be converted to a liquid state and be highly pressurised (200 bar or more). Unloading cylinders containing highly pressurized liquid gas poses considerable safety risks. Given that companies have serious responsibilities regarding the health and safety of all staff members, avoiding the need to interact with bottled nitrogen is beneficial.

On-site nitrogen generation eliminates the need for high-pressure storage cylinders, reducing potential hazards.

The latest Atlas Copco nitrogen generators allow staff to avoid exposure to liquid nitrogen gas, removing the potential for serious burns or other injuries. Installed generator systems minimise direct operator involvement, making the nearby working area safer.

3. Reduced Carbon Footprint

Industrial companies are keen to reduce their carbon footprint. Being seen as environmentally friendly is essential when pursuing greener business practices. This applies whether operating a lab, managing a brewery, or packaging food as a food processor.

Sidestepping a supply chain dependence on regularly delivered bottled nitrogen keeps delivery vehicles off the road. This reduces the company’s carbon footprint in a meaningful way. For a manager responsible for their facility’s environmental impact, it’s an easy win-win.

Additionally, on-site nitrogen generation systems often include energy-efficient technologies, such as pressure swing adsorption (PSA) or advanced membrane designs, further minimising energy usage.

Also, using gas deliveries means converting gas to a liquid state for transportation, and then returning it to a gaseous state post-delivery. Both processes use energy and other resources wastefully, which affects the environment.

Onsite nitrogen generation avoids these types of unnecessary conversions altogether.

4. Cost Savings

The cost of delivered liquid nitrogen is considerable, often supplied at higher pressures than necessary, which pushes up expenses. Storage tank leaks also mean around 10 per cent of the gas is lost during transit – a hidden cost many businesses overlook. Add in delivery charges, fluctuating energy prices, and administrative overheads, and managing energy supply becomes a real challenge.

On-site production helps overcome these energy challenges. Gas is generated only when needed, avoiding storage losses and costly deliveries. Modern systems, like Atlas Copco nitrogen generators, spin up in seconds, ensuring a fast and efficient supply without waste.

Crucially, on-site generation offers cost predictability. Without delivery price spikes or hidden fees, businesses can more accurately control their operating budgets. Many companies recover their investment within 12 to 18 months, dramatically reducing utility costs over time.

Further savings come from the energy efficiency of modern membrane and PSA generators, helping to lower energy bills and support greener operations.

In short, on-site production cuts hidden costs, shields against market fluctuations, and brings long-term financial stability.

5. Control the Purity

Purity levels are a major concern for nitrogen users. Depending on the purpose and machinery utilising the nitrogen, a certain purity level is required. Regrettably, delivered nitrogen often arrives over specified. Here, businesses pay for a higher level of pressurisation than necessary and pay the price for the privilege.

By opting for onsite nitrogen generation, your staff controls the purity level directly from the generator’s control panel. With membrane generators, purity is achievable up to approximately 99.9% or so. However, when exacting requirements necessitate a 99.999% purity, then only a pressure swing adsorption generator will do.

For industries requiring ultra-high purity (99.999%), pressure swing adsorption (PSA) nitrogen generators offer precise control and unmatched performance.

6. Save Floor Space

Holding a gas storage tank or multiple standing gas cylinders on the premises takes up floor space. This space is better utilised by machinery or used for other purposes.

An unhappy trade-off is necessary between the amount of nitrogen gas stored versus the space it occupies. The intention is to avoid ever completely running out of gas for production. Many times, the gas cylinders are rented, too. So, there’s financial pressure not to have too many full tanks sitting around before they’re used.

While the onsite gas generation equipment clearly takes up floor space, the equipment itself is compact. There are no awkward deliveries to contend with or pesky storage issues. Nitrogen is no longer a headache to deal with.

Compact, skid-mounted systems are now available, allowing seamless integration into existing facilities.

7. Improve Existing Industrial Processes by switching to Nitrogen

In some situations, it’s possible to use nitrogen as a replacement. This may be optimal from a production or a financial cost standpoint but wasn’t considered sensible when not having direct control over the production of necessary gasses.

One example of this is breweries that previously used oxygenation in their processes but later switched to nitrogenation instead. This got around supply bottlenecks of CO2 and potential price spikes that play havoc with raw material estimates within management accounts. It also lowered the carbon footprint too.

Similarly, nitrogen can replace CO2 in modified atmosphere packaging (MAP) to preserve food freshness and extend shelf life.

Let Anglian Compressors, a Branch of Atlas Copco Compressors, Offer Guidance

Making a change from nitrogen deliveries and storage to on-site nitrogen generation is not a small matter. Gas is a core material necessary for advanced production for many businesses. Therefore, it pays to consult with an expert team, such as ours, at Anglian Compressors, a Branch of Atlas Copco Compressors.

We can discuss which type of nitrogen generator would be best and how it should be implemented, ensuring minimal disruption to existing operations.

Contact us below.

FAQ

What are the benefits of on-site power generation for businesses?

On-site power generation allows businesses to produce their own gas or energy directly at the point of use, reducing reliance on external suppliers. This improves energy security, offers greater control over costs, and supports environmental goals by dramatically reducing energy costs and carbon emissions. It also protects operations from fluctuations in the wider energy industry.

How does on-site gas production help lower utility costs?

On-site gas production eliminates delivery charges, minimises storage losses, and reduces waste, helping businesses lower their overall utility costs with onsite power. By generating only what is needed, companies gain cost predictability and shield themselves from rising energy prices or supply disruptions.

Is on-site gas generation part of the shift towards distributed energy solutions?

Yes, on-site gas generation is a key part of the growing move towards distributed energy resources. Rather than depending on centralised suppliers, businesses are increasingly adopting distributed energy generation methods to improve resilience, cut emissions, and secure a more sustainable future for their operations.