Air Compressor Monitoring System – What Is It and Why Do You Need One?

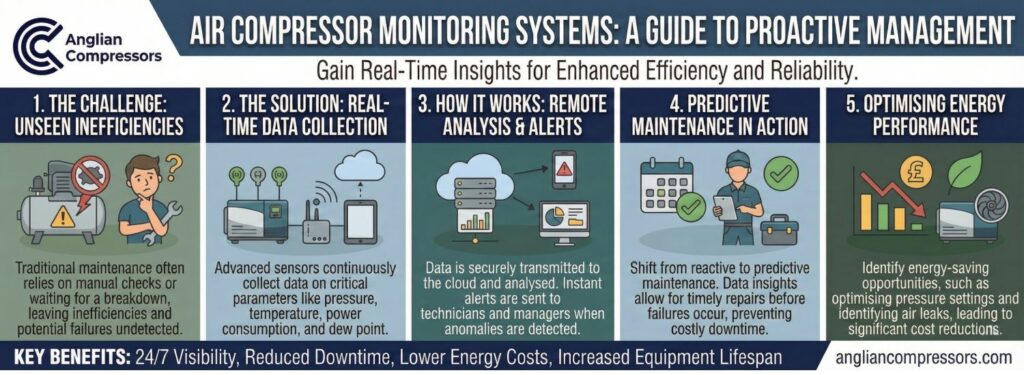

Imagine having a constant eye on your critical air compressor systems, even when you’re miles away. That’s the power of a modern air compressor monitoring system. These intelligent systems provide real-time insights into your equipment’s performance, alerting you to potential problems before they escalate into costly downtime.

Gone are the days of relying on manual check-ups and hoping for the best. Air compressor monitoring systems mark a significant shift towards proactive maintenance and enhanced operational efficiency. By providing real-time data and alerts, these systems empower businesses to:

- Prevent costly equipment failures with predictive analytics

- Optimise performance and efficiency through tailored insights

- Gain valuable operational insights to make data-driven decisions

This article will delve into the benefits of air compressor monitoring systems, exploring their features and why they are an invaluable tool for any business reliant on compressed air.

What are Air Compressor Monitoring Systems?

At their core, air compressor monitoring systems track and analyse critical data points, providing a comprehensive overview of your equipment’s operation. This data can encompass a wide range of parameters, including:

- Vibration Analysis: Detects abnormal vibrations that could indicate impending bearing failure or other mechanical issues.

- Temperature Monitoring: Tracks operating temperatures to prevent overheating and ensure optimal performance.

- Pressure Sensors: Monitor system pressure to pinpoint leaks, pressure drops, and irregularities, reducing energy wastage.

By continuously analysing this data, these systems can detect subtle changes that might otherwise go unnoticed, allowing you to address issues proactively before they escalate into costly downtime.

SMARTLINK and SMARTVIEW

Advanced systems like SMARTLINK and SMARTVIEW utilise digital analytics to provide unparalleled insights into compressor efficiency and health. These intelligent platforms offer:

- Cloud-Based Access: SMARTLINK uses smartphones or tablets to ensure real-time visibility from anywhere.

- Remote Access and Control: Monitor and manage your compressors from anywhere with internet access.

- Real-time Data Visualisation: Track key performance indicators through intuitive dashboards and reports.

- Predictive Maintenance Alerts: Receive timely notifications about potential problems, enabling you to schedule maintenance before failures occur.

Importance of Monitoring Air Compressors

Air compressor monitoring systems provide a proactive approach to maintenance, efficiency optimization, and risk mitigation.

1. Enhanced Workplace Safety: A Top Priority

Above all else, monitoring your air compressor is paramount for workplace safety. By providing real-time data on system pressure, temperature, and other crucial parameters, these systems act as an early warning system for potentially dangerous situations. Identifying and addressing issues like overpressure or abnormal temperature fluctuations can prevent accidents, ensuring a safer work environment for everyone.

This proactive monitoring mitigates risks and ensures compliance with workplace safety standards.

2. Preventing Costly Downtime: Proactive Maintenance is Key

Unscheduled downtime due to equipment failure can cripple productivity and eat into your bottom line. Air compressor monitoring systems enable a proactive approach to maintenance, minimising the risk of unexpected breakdowns. By continuously tracking system health and performance, these systems can detect subtle anomalies that often precede major failures. This early detection allows you to schedule maintenance at your convenience, minimising disruption to your operations. This ensures seamless scheduling of maintenance tasks, reducing disruptions to operations.

3. Unlocking Efficiency and Savings: Maximising Performance

Monitoring your compressed air system isn’t just about preventing problems—it’s also about optimising performance. By tracking key parameters like air flow, pressure, and energy consumption, these systems can identify inefficiencies that are often invisible to the naked eye. For example, detecting a leak early can save you significant energy costs over time. Similarly, identifying a clogged air filter can improve compressor efficiency and reduce wear and tear on the system. For example, systems like SMARTLINK can identify even minor leaks, helping businesses save significantly on energy costs over time.

4. Extending Equipment Lifespan: Protecting Your Investment

Air compressors are a significant investment, and maximising their lifespan is essential for a strong return on that investment. Regular maintenance is crucial, but knowing when maintenance is needed is equally important. Monitoring systems provide the insights you need to make data-driven decisions about maintenance schedules. By addressing issues early and ensuring the system operates within its optimal parameters, you can significantly extend the life of your compressor. Monitoring systems ensure timely servicing by analysing trends and avoiding unnecessary wear and tear.

5. Data-Driven Insights for Smarter Decisions

Perhaps the most powerful benefit of air compressor monitoring systems is the wealth of data they provide. This data offers valuable insights into your system’s performance, usage patterns, and potential areas for improvement. These insights can inform better decision-making in various areas, from optimising maintenance schedules and energy consumption to making informed decisions about future equipment upgrades. Customised reports from systems like SMARTVIEW allow businesses to optimise their operations comprehensively, from energy efficiency to future equipment upgrades.

Choosing the Right Monitoring System

Choosing the right system for your specific needs is crucial for maximising its value and ensuring a seamless integration with your existing operations. Here’s what to consider:

- Central Controller Setup: Advanced systems like SMARTVIEW optimise entire networks of compressors with integrated controllers.

- Compatibility: Ensure the monitoring system is compatible with your existing compressor equipment, sensors, and control systems.

- Scalability: Opt for a system that can grow alongside your operations, easily accommodating additional compressors or sensors as your demands change. Scalability future-proofs your investment and saves you from having to replace the entire system down the line.

- Remote Accessibility: Choose a system with a user-friendly interface accessible from any device with an internet connection, allowing you to stay informed and address potential issues no matter where you are.

- Alerts & Notifications: Look for a system that provides customizable alerts via email, SMS, or even mobile app notifications, informing you immediately of any unusual readings, potential faults, or upcoming maintenance requirements.

- Data Analysis: Find a system that translates complex data into actionable insights through clear dashboards, reports, and trend analysis tools.

- Support and Maintenance: Ensure your chosen vendor offers reliable customer support, including installation assistance, troubleshooting, and ongoing maintenance options.

Choosing the right air compressor monitoring system doesn’t have to be overwhelming. At Anglian Compressors, a Branch of Atlas Copco Compressors, we understand that every business is unique. Our expert team is here to guide you through the selection process, recommending the ideal system to meet your specific needs and ensure seamless integration with your existing setup.

Integration with Existing Systems

Integrating an air compressor monitoring system into your existing setup is straightforward with proper planning. The key steps include:

- Sensor Placement: Sensors are installed on your air compressor’s key components to monitor parameters such as pressure, temperature, and vibration. These sensors allow you to monitor your compressed air system without requiring major modifications.

- Network Connection: Sensors connect to a central controller via wired or wireless networks, such as Wi-Fi or SCADA, enabling seamless data flow, as well as the monitoring and control of your system from any location.

- Software Configuration: Once the hardware is set up, configure the software to continuously monitor your compressor’s performance, set alert thresholds, and customise dashboards to visualise data in a manner that simplifies management.

- Remote Access: Systems like SMARTLINK offer remote access, allowing you to check the status of your air compressors and respond to potential issues without needing to visit the compressor room.

- Central Controllers: For systems with multiple compressors, central controllers gather data from each compressor and optimise the performance of the entire compressed air system by providing detailed analysis and reports.

Focusing on compatibility with your existing equipment and scalability ensures seamless integration. With remote monitoring, you can enhance reliability and efficiency, keeping your compressed air system running smoothly around the clock.

Types of Air Monitoring Systems

There are several types of air monitoring systems available to suit different needs and applications. Here are the common types:

Continuous Monitoring Systems

Designed to provide real-time data on air quality, continuous monitoring systems use sensors to measure various air pollutants and report the data back to a central monitoring station. They are ideal for industrial environments where air quality needs to be constantly monitored.

Passive Sampling Systems

Passive sampling systems use special filters or adsorbents to collect and measure pollutants in the air. The samples are then analysed in a laboratory to determine the levels of different pollutants. These systems are ideal for long-term monitoring or for collecting data over an extended period.

Spot Monitoring Systems

Spot monitoring systems are used to measure air quality at specific locations or for a specific period of time. They are typically used to evaluate air quality in a specific area or to measure the effectiveness of an air pollution control strategy.

Portable Monitoring Systems

These systems are designed for use in the field and can be easily moved to different locations. They are typically used for short-term monitoring or for investigating specific air quality concerns.

Remote Monitoring Systems

Remote monitoring systems use telecommunication technology to transmit data and monitor data traffic from a remote location to a central monitoring station. They are typically used in remote or hard-to-reach areas where continuous monitoring is required.

By carefully evaluating your options and understanding the features of each system, you can select the right air monitoring system to meet your specific needs.

Tips for Implementing an Air Compressor Monitoring System

Are you looking for ways to make sure your air compressor monitoring system is functioning optimally? Here’s what you need to do:

- Develop a detailed plan outlining the objectives and steps of implementation, so that you can stay on track and make sure the system meets your needs.

- Evaluate your current air compressor systems and control equipment to make sure the system selected is compatible with them.

- Engage all stakeholders in the implementation process – from operators, to maintenance personnel, to management – so everyone understands their role in realising the objectives of the monitoring system.

- Provide training for personnel on operating the new system, so they are comfortable and confident when using it.

- Thoroughly test and evaluate it’s performance once it is up and running. Make any necessary adjustments to ensure optimal operation.

- Monitor the system continuously and schedule regular maintenance checks so that any issues can be identified early and prevented from escalating into bigger problems.

If these tips are followed correctly, improved energy efficiency will be achieved with your air compressor monitoring system – guaranteeing peak performance at all times.

Atlas Copco Compressor Monitoring System

It’s important to pick the system that is right for you. Anglian Compressors are proud to be a premier distributor and a Branch of Atlas Copco Compressors, offer two types of monitoring systems with distinct benefits.

First, there is a cloud-based system called SMARTLINK. It allows your team to check in on your compressor and its performance from anywhere. All you need is a smartphone or a tablet.

The second system – SMARTVIEW – uses a local area network which when connected to a central controller, enables advanced technical analysis of compressor data. This is particularly important in today’s economic climate of high energy prices.

Rest assured, our team of Air Compressor experts will help you choose the right monitoring system to suit your needs.

Final Thoughts

An air compressor monitoring system provides real-time monitoring and alerts for any unexpected issues, helping to prevent accidents, improve efficiency and extend the life of the equipment. By investing in this technology, businesses can take a proactive approach to ensure optimal operation while cutting down on energy consumption.

Investing in this technology ensures operational excellence while achieving measurable cost savings and sustainability goals.

The tangible benefits and added peace of mind that come with this system make it a must-have tool for anyone who relies on air compressors. Get in touch with us if you need help choosing a monitoring system- our installation and after-sales maintenance services are second-to-none.

FAQ

How can an air compressor monitoring system enhance the efficiency of my compressed air system?

An air compressor monitoring system allows you to track key parameters such as pressure, temperature, and energy consumption in real time. By providing detailed data, the system helps detect inefficiencies like leaks or excessive energy use. This proactive approach ensures your air compressors operate at peak performance, significantly improving the overall efficiency of your compressed air system while reducing unnecessary power consumption.

Can I access my air compressor’s status remotely, and how does that benefit my operations?

Yes, many modern monitoring systems, such as SMARTLINK, offer remote access to your air compressor’s data. This allows you to check the status of your compressors without needing to visit the compressor room. Remote monitoring enables you to keep an eye on performance and respond to potential issues instantly, ensuring reliability and minimising downtime.

How does a monitoring system improve the reliability of my compressed air system?

A monitoring system that utilises real-time data and predictive analytics helps ensure air compressors are performing consistently. By tracking key parameters, the system provides early alerts for potential issues, allowing for timely maintenance. This not only enhances the reliability of your compressed air system but also helps prevent costly shutdowns and unplanned downtime.