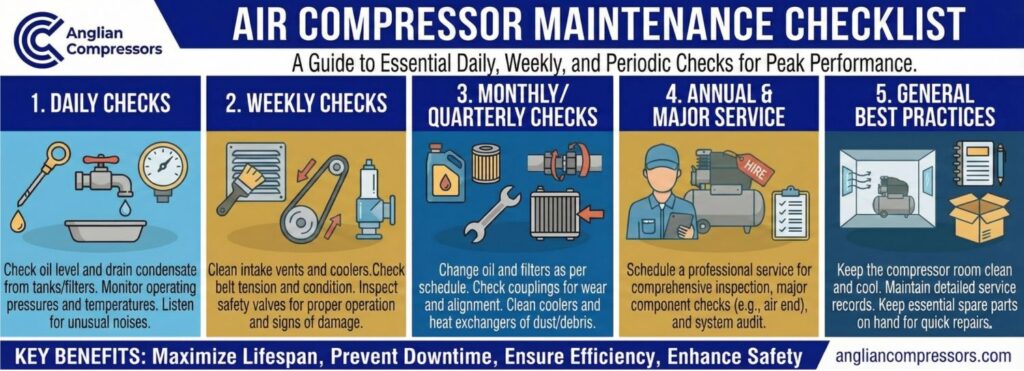

Air Compressor Maintenance Checklist

Air compressors require regular and consistent maintenance to ensure long-term reliability and optimal performance. Energy efficiency levels are maintained through the use of an air compressor maintenance checklist. Using one avoids overlooking key steps to keeping existing equipment in tip-top shape.

Neglecting maintenance by postponing it can have serious consequences. Breakdowns become more frequent and severe when equipment is not properly cared for. For instance, a broken part may result in further internal damage. Operating equipment without the necessary maintenance reduces its potential lifespan.

One approach to creating a consistent routine maintenance process is through the use of a structured checklist. Instead of always being reactive, it helps guarantee that maintenance is carried out at the appropriate time.

Understanding Air Compressor Maintenance

Even the best-in-class machinery eventually fails. A part can become worn, and inadequate lubrication increases wear, reducing its reliability and lifespan.

Air compressor maintenance is all about taking care of your expensive equipment to get the highest performance and avoid breakdowns. When repairs or part replacements are needed, proactively completing these tasks avoids the necessity of reactive repairs later.

Some factors that influence preventative maintenance schedules include compressor types (piston vs rotary), environmental conditions (cold, heat, dust, and noise), and usage requirements.

Depending on the checklist and schedule, regular inspections should initially focus on the hoses, belts, intake filters, condensate drains, and control panel systems.

For assistance with creating your maintenance checklist, contact Anglian Compressors, a Branch of Atlas Copco Compressors. Our experts can guide you through the process.

Daily Air Compressor Maintenance Tasks

Below are some daily routine maintenance tasks:

Lubricants: oil is frequently used as a lubricant in a compressed air system. Insufficient oil leads to damage to internal components. Check the oil levels and replenish them as necessary.

Condensate Management: manually drain condensate or examine the auto-drain functionality to ensure it operates correctly. The accumulation of condensate within machinery raises internal moisture levels and adversely affects the quality of the compressed air.

Air Pressure: review air pressure levels and operating temperatures for unexpected deviations.

Odds and Ends: examine the air system for unusual noises, vibrations, air leaks, and verify that the operating conditions are as expected.

Weekly Maintenance Checklist

To maintain your air compressor, begin by inspecting and cleaning your air intake filters each week. They accumulate dirt and debris as air is pulled through them.

Examine each hose and fitting visually. Check for any cracks. Look for air leaks, as these can be expensive if left unchecked.

Perform a test on each of your safety devices to verify reliability. Test system shutdown processes to confirm they operate as expected.

Review the coolant for issues. Check for oil leaks, such as oil pooling in spots where it should not be collecting.

Monthly Air Compressor Maintenance

Monthly professional maintenance detects any problems before they become serious. They do not need to be reviewed more frequently, but they are equally vital.

Belt Condition: inspect the belts for tension issues. Tighten the belt tension where necessary. Belts with slack in them reduce performance.

Dust Removal: wipe away any accumulated dust on external equipment surfaces. This helps the equipment to stay cooler.

Drain Valves: test whether the automatic drain valves are functioning as required. This prevents moisture buildup.

Minimise or Reduce Vibrations: verify that all vibration isolators are present. Fasteners also must be secure to prevent unwanted movement.

Quarterly or Biannual Tasks

Even for quarterly or biannual periods, maintenance is crucial. Set a reminder to avoid forgetting the less frequent maintenance requirements.

Replace the oil based on usage and the equipment. A rotary screw compressor has a different lubrication type and needs compared to an oil-free compressor model. Compressor motors and bearings may also require grease or other lubrication.

Air filters and oil filters become clogged and must be changed to maintain operational efficiency. Internal components are better protected when filters are periodically replaced. Ensure there are sufficient filter replacements on hand.

Electrical components are susceptible to wear and tear, as well as overheating. Examine all the contactors and wiring to determine which ones need to be replaced.

Annual Air Compressor Maintenance

Achieving optimal performance for your compressed air system includes annual maintenance.

Safety Valve Testing – test the pressure relief valve to verify it functions as expected. These are required as part of safety compliance.

System Audit or Air Audit – perform or order either a full system audit or an air audit to look for significant energy losses, inefficiencies, or air leaks. These issues are costly due to wasted energy and increased air production to account for system losses.

Maintenance Logs – examine and keep track of the air system’s logs. These provide traceability and information for an external team audit by outlining the steps taken.

Full Diagnostic and Service – book a qualified service engineer to complete a comprehensive service and a thorough diagnostic to pinpoint any issues.

Anglian Compressors, a Branch of Atlas Copco Compressors, regularly performs air audits and system audits for our clients. Is it time for your next one?

Common Mistakes to Avoid

1. Skipping regular condensate drainage results in equipment damage and earlier-than-expected metallic rust development.

2. Using the wrong lubricants or inferior-grade replacement parts. Both pose different types of risks to the air compressor system.

3. Failing to tighten the belt. Belt slippage, additional wear, and production delays can result.

4. Air or oil filters are not replaced frequently enough. This impacts air quality and compressed air flow rates.

Tools and Supplies You Will Need

Some suggested maintenance tools and supplies are as follows:

- Torque wrench to tighten bolts and other fittings to meet requirements.

- OEM-approved oils, lubricants, air filters, and oil filters as needed.

- Cleaning supplies for enclosures, fan guards, and intake screens.

- Digital CMMS or a maintenance logbook to record completed maintenance tasks.

Tips for Creating a Maintenance Culture

Below are some useful maintenance tips for industrial air systems.

Operator Training: train air system staff to perform daily checks and escalate serious concerns as early as possible.

Visual Checks: utilise a visual checklist to identify what to look for near installed equipment. Alternatively, digital reminders are effective.

Stock Essential Spare Parts: maintain a stock of essential spare parts. Prevent delays in operations by avoiding the need to order and wait for parts to arrive.

Service Agreements: establish a service agreement with a reliable air system provider.

Conclusion

Using an air compressor maintenance checklist is vital. It helps to maintain system compliance and performance levels, reduces potential downtime, and saves money.

A structured, consistent approach to maintenance is necessary. Avoid ad hoc approaches, which inevitably overlook something important. Instead, use checklists to ensure everything is examined frequently enough to prevent issues.

If you want to improve your company’s approach to air system maintenance or believe an air system audit might be timely, please get in touch.