AI and Predictive Maintenance in Compressed Air Systems

Artificial intelligence (AI) is now utilised in various industries, primarily to enhance system performance. Industrial maintenance relies on scheduled maintenance procedures based on a calendar system. This identifies obvious problems but also allows for proactive steps to discover issues at an earlier stage.

Compressed air systems are a vital component of many modern business operations. Whether producing compressed air to power pneumatic equipment, operating paint sprayers in a workshop, or maintaining factory equipment, this type of stored energy is referred to as a fourth utility.

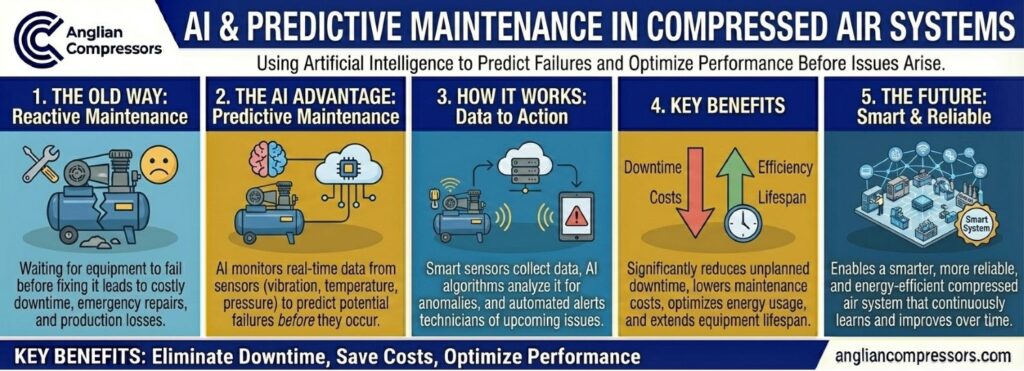

Compressed air systems have gradually moved away from preventative maintenance to predictive maintenance. This includes the use of AI to predict operational performance issues before they occur.

In our latest blog post, we explore how AI is revolutionising air compressor maintenance by utilising groundbreaking sensors and machine learning to minimise downtime.

The Role of AI in Enhancing Compressed Air System Efficiency

Air compressor operations limit potential issues and unexpected downtime through real-time data analysis. AI systems continuously monitor sensor data. This allows artificial intelligence to review each dataset and individual variables (e.g., airflow, motor RPM, bearing status, and oil tank temperature) for unexpected variances. By sensing minor changes in operation performance, the compressor’s predictive maintenance strategy is improved.

Using AI and machine learning, system parameters are adjusted based on expected outcomes and to achieve optimal performance. Such changes occur in real time and are entirely automatic. As a result, energy consumption is reduced and overall performance is improved.

In one example, Wistron Corporation (a former manufacturing partner to Acer) relied on an AI air compressor control system to reduce carbon emissions by 41 per cent across its network of factories worldwide.

Predictive Maintenance Explained

Predictive maintenance is a needs-based model, rather than a scheduled, preventative maintenance model. This requires a different mindset and approach compared to other maintenance procedures. Maintenance is performed only as needed. This reduces the time spent on equipment maintenance, allowing operations to achieve higher production hours.

The role of preventative maintenance relies on taking a systematic approach. Standard routines are established to ensure all equipment is regularly maintained. This approach is neither intuitive nor shrewd. By contrast, a predictive maintenance method leverages AI and machine learning to apply smart system monitoring and to deliver ad hoc maintenance whenever needed.

Ultimately, the predictive maintenance model has the edge over reactive maintenance. It proves timelier and more cost-efficient for busy operations.

Interested in the benefits of predictive maintenance for air compressors? Contact Anglian Compressors, a Branch of Atlas Copco Compressors, to discover how we can implement predictive maintenance in your business.

AI-Driven Predictive Maintenance Technologies

The types of technologies that support AI-driven predictive maintenance include Internet of Things (IoT) devices, various sophisticated sensors, and machine learning algorithms. Machinery that relies on IoT technologies communicates with other equipment to ensure better operational support and functionality.

Utilising AI in a monitoring system performance involves integrating various equipment and receiving data streams from built-in sensors. Continuous monitoring through machine learning influences operators and often automatically adjusts parameters when results deviate from expectations. The machine learning model gradually enhances outcomes by improving its understanding of equipment performance, unusual deviations, and how to compensate for them.

Advanced monitoring systems observe minor deviations in performance. It is easy for equipment operators to overlook small deviations. However, AI systems learn about managed compressed air systems to make progressively smarter decisions. In so doing, they become better able to predict potential failures when parts malfunction, begin to underperform, or exhibit other non-standard issues.

Challenges and Considerations

Switching from reactive maintenance to a predictive model is not without its challenges and other considerations.

The deployment of an AI monitoring system necessitates a significant upfront financial investment and extensive training. Successful integrations are difficult, and some employees require specialised knowledge to take full advantage of the system’s capabilities. Data security is another crucial factor. Protecting centralised data collection is essential.

Deploying and fully integrating an AI-based predictive maintenance system is significantly simplified when working with an air compressor specialist like Anglian Compressors, a Branch of Atlas Copco Compressors. We can overcome complications more easily. Also, system complexity is no longer a significant obstacle.

Skilled personnel are required to both manage and correctly interpret AI systems, alerts, and feedback. As such, the compressor user must invest in the right personnel and training systems. Additionally, it helps to periodically retrain to stay up to date on updates.

Anglian Compressors, a Branch of Atlas Copco Compressors, helps steer our clients through AI integrations to obtain the best results. Please get in touch for more information.

Future Trends in AI and Compressed Air Systems

Proactive maintenance models are the future for air compressor users. Maintenance can help improve performance, but AI is here to stay. Given the high cost of energy during operations, even minor adjustments that increase operational efficiency and lower power expenditures prove worthwhile.

Machine learning models are still developing. They will be far more capable in the future than they are now. Better algorithms can be incorporated into systems to leverage their expanding feature set. The most recent integration is access to renewable energy resources. The majority of compressor users have not yet effectively reduced their high energy costs by utilising renewable energy.

Smarter maintenance models that require less direct involvement are quickly becoming the norm in industrial maintenance. Consequently, production shutdowns and other planned maintenance will become less frequent.

Conclusion

For compressed air systems, predictive maintenance is replacing preventive maintenance. AI control technologies save energy costs while enabling businesses to efficiently manage intricate air systems.

A more proactive approach to maintenance leads to cost savings on parts replacement, greater operational efficiencies, and fewer breakdowns. While advanced AI systems do require staff retraining and significant capital investment, they yield long-term benefits that pay dividends.

Companies should fully embrace AI technologies before their competitors do. Otherwise, they risk falling behind in their respective marketplaces when their industry peers adopt machine learning and other advances sooner.

Anglian Compressors, a Branch of Atlas Copco Compressors, is perfectly positioned to help your business transition to a predictive maintenance model for its compressed air systems.