A Guide to Air Compressor Maintenance

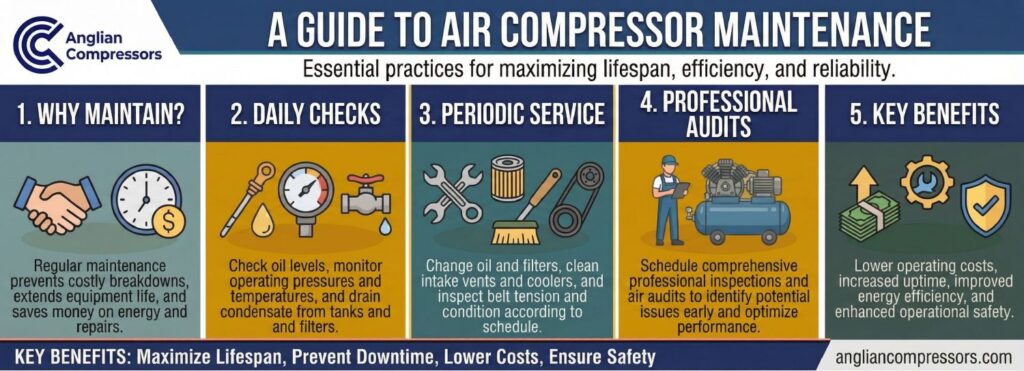

Industrial air compressor systems are built for durability, but like any hardworking machine, they need regular attention. Without proper air compressor maintenance, issues such as blocked inlet air filters, moisture build-up in the air receiver tank or oil contamination can gradually reduce compressor efficiency and lead to costly downtime.

This air compressor maintenance guide outlines essential maintenance activities to help you keep your air compressor running efficiently. Regular maintenance checks, such as replacing air filters and draining the air tank, can extend the life of your compressor and protect your air supply.

Whether you follow a preventative maintenance schedule or need professional maintenance support, Anglian Compressors, a Branch of Atlas Copco Compressors, is here to help you get the most out of your compressed air equipment.

Introducing Anglian Compressors, a Branch of Atlas Copco Compressors

At Anglian Compressors, a Branch of Atlas Copco Compressors, we have been a leading supplier and installer of compressed air solutions and industrial equipment for a variety of UK industries for nearly five decades. As a premier distributor for Atlas Copco since 1977, we settle for nothing but the most pioneering solutions for our clients. We are fully qualified to handle maintenance and inspection tasks, including the written scheme of examination (WSE).

Keep reading for key insights into DIY air compressor maintenance and what to expect when hiring professionals. Do not hesitate to call us if you want to discuss your needs during a no-obligation consultation.

Why Air Compressors Need Maintenance

Like all other industrial equipment, air compressors wear with time and usage. However, you can extend the lifespan of your compressor, components, and associated equipment by inspecting critical components frequently.

In short, staying on top of air compressor maintenance can help you:

Prevent Costly Equipment Failures

By maintaining your compressor correctly, you can catch minor problems before they spiral out of control and result in equipment failures that can be costly to put right.

Minimise the Risk of Business Downtime

Equipment breakdowns and failures can cause your operations to come to a standstill, and any business downtime can cost you a small fortune. Preventing breakdowns ensures you can always operate your business smoothly.

Maximise the Efficiency of Your Equipment

Clogged filters, valves and other small problems can all decrease the energy efficiency of your compressor, leading to unnecessarily high electricity bills.

Remain Compliant

All UK businesses that use pressure systems such as compressors must comply with quality and safety standards. Staying on top of maintenance helps you stay on the right side of the law and avoid potentially costly fines.

Essential Maintenance Tips for Air Compressors

A proper air compressor maintenance routine is crucial for keeping your compressor running efficiently and preventing unplanned downtime. Whether you are maintaining a screw compressor or another type of system, these basic tasks form the foundation of any reliable maintenance plan.

Read the Manual

Every specific compressor model is different. The manual provides essential maintenance guidelines, including oil types, filter schedules, and recommended maintenance intervals.

Drain the Air Receiver Tank

Moisture naturally builds up in the tank during use. Draining it regularly helps protect your air lines, maintain air pressure, and prevent damage to your air compressor’s components.

Clean or Replace the Air Filters

Blocked inlet air filters reduce airflow, allowing dirt to enter the compressor. Clean air filters ensure clean air enters the system, reducing strain and helping maintain your air compressor’s efficiency.

Check the Belt

A worn or loose belt affects how the compressor operates. Check regularly for signs of wear or tension issues to ensure the compressor runs smoothly.

Change the Compressor Oil

For lubricated units, fresh compressor oil is critical. Follow your maintenance schedule and always use the oil specified for your compressor model.

Check for Leaks

Air leaks reduce pressure and waste energy. Listen to fittings and valves, and repair or replace parts as needed to ensure the compressor operates efficiently.

Keep the Area Clean and Ventilated

Dust and debris can block the air intake and cooling system, potentially causing damage. Keeping the area clean helps maintain airflow, supports air dryers, and protects the quality of air entering the compressor.

By following this simple air compressor maintenance checklist, you can prolong the life of your compressor, lower energy costs, and prevent unexpected breakdowns. Preventive maintenance helps ensure long-term performance and reliability.

Air Compressor Maintenance Schedule

Different compressors in different environments have different maintenance requirements. However, here is a general overview of what your schedule might look like:

- Daily: drain the tank, check for air leaks, and inspect all safety devices.

- Weekly: clean all intake vents and filters and inspect the belt for signs of wear and tear.

- Monthly: inspect safety valves, test auto drain systems and clean the cooling fins.

- Quarterly: recalibrate pressure gauges and replace the oil and filters.

- Annually: organise a professional inspection by an experienced expert.

Book a Professional Inspection Today

Staying on top of maintenance can save you a small fortune in the long run. Basic tasks like changing the oil and cleaning the filters can help your compressor run more efficiently while minimising breakdowns and downtime. It is a small investment of time that can do wonders for your compressors. However, it is best to leave certain maintenance and inspection tasks to the professionals.

At Anglian Compressors, a Branch of Atlas Copco Compressors, we provide a broad range of comprehensive maintenance services that could add years to the lifespan of your compressors and attached equipment. We have you covered whether you need energy audits, a written scheme of examination, air quality testing or leak detection; you will not find more reliable or high-value services elsewhere.

The next time you need a professional compressor inspection, look no further than Anglian Compressors, a Branch of Atlas Copco Compressors. Contact us today to organise a no-obligation consultation at a time that works for you.

FAQ

How often should you maintain your air compressor?

Regular air compressor maintenance is essential to keep your system running efficiently. A routine maintenance schedule, including checks on filters, oil, and air inlets, helps prevent breakdowns and supports long-term performance. Regular maintenance ensures fewer faults and better energy efficiency over time.

What does proper maintenance of air compressors involve?

Proper maintenance involves more than just checking the pressure. It includes cleaning or replacing filters, draining moisture, inspecting air inlets, and following a step-by-step guide specific to your compressor model. Preventive maintenance helps keep the air clean, protect internal parts, and reduce the risk of costly repairs.

Why is servicing your air compressor important?

Servicing your air compressor is essential because it keeps your equipment in peak condition. Preventive maintenance and servicing ensure clean air delivery, prolong system lifespan, and reduce the chances of unexpected downtime. Maintaining your air compressor also supports safe and efficient use of the air supply.