Air compressors are essential for many businesses and are found in almost every sector.

They drive processes ranging from heavy-duty machining to delicate food preparation. However, their versatility is dependent on regular servicing.

Air compressors become inefficient without a proper maintenance and repair routine, costing you more to run or even failing to provide the power you rely on.

A good servicing plan can keep your compressor as good as new. We can service any compressor brand, and our extensive range of plans will include something right for your installation.

Why is air compressor service and repair important?

Like any equipment, compressed air equipment will experience wear and tear and suffer the occasional bumps and knocks that can happen in any operational location. Given that it will be used in demanding circumstances, the need for some servicing is inevitable.

One of the ways an unserviced compressor will affect you is your bottom line. A regular maintenance routine ensures every component in your system performs as it should, helping to maintain compressor efficiency and saving you up to 20% on energy costs. Some problems, such as air leaks, can be even more costly—a single, small leak can cost over £1,000 per year in wasted energy—and increase the strain on your compressor, potentially creating costly repairs or breakdowns.

In some industries, regular servicing is essential to meet regulatory and safety standards. In the UK, businesses must comply with the Pressure Systems Safety Regulations 2000 (PSSR), which mandates a 'Written Scheme of Examination' (WSE) for most compressed air systems. Our compliance packages help you manage this legal requirement. Additionally, specific standards like ISO 8573-1 cover the purity of the air produced, including the standards that must be met for compressed air used in critical food, pharmaceutical, and electronics operations.

Like any equipment, keeping it in good running order minimises unexpected breakdowns and production losses. With unplanned downtime costing industrial facilities thousands of pounds per hour, this proactive approach is essential to maximise uptime and efficiency. A well-maintained system is estimated to experience less than 50% unplanned downtime.

How do I maintain my compressed air system?

Good maintenance never stops, and you should check your compressor daily. In addition to checking the pressure, temperature, and oil levels, those who work with it may see early signs of problems, like changes in operating noise or vibration.

Quick but regular system checks should supplement this. Examining pipework, connections, and hoses can help identify issues before they become more serious.

The importance of regular servicing

These internal checks should be supplemented by a proper servicing and preventive maintenance plan. Your operations will determine the frequency of these checks, and we are always happy to advise.

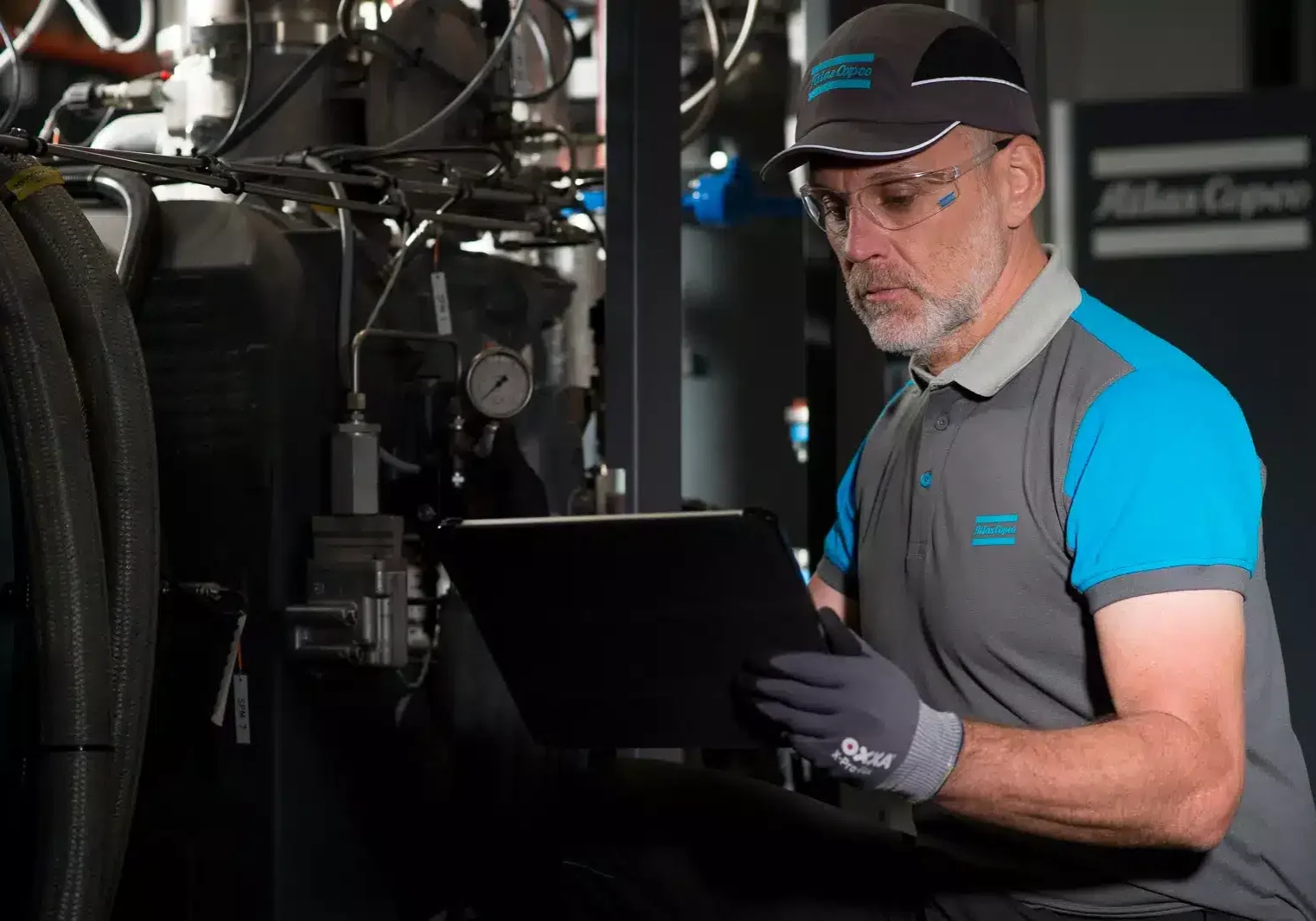

Having one of our experienced engineers attend site means your compressor will have a full check, with all parts assessed and replaced as needed, using genuine parts to ensure optimal performance and protect your warranty.

Our services may include diagnostics using technology like an ultrasonic tool to detect leaks too small for humans to notice, or thermal imaging to identify heat anomalies.

The benefits of professional servicing and repair

It is, of course, possible to service your compressed air system in-house, but there are significant benefits to using the experts from Anglian Compressors, a Branch of Atlas Copco Compressors.

We have been installing and servicing air compressors since the 1970s, becoming trusted partners to businesses that rely on us to keep their compressors working.

Certified Technicians

Although we service all makes and models of air compressors, including piston compressors and rotary screw compressors, our partnership with Atlas Copco means we benefit from the highest level of factory trained and certification from one of the world’s leading air compressor manufacturers.

Through Anglian Compressors, a Branch of Atlas Copco Compressors, your system will have access to the latest thinking and technology in compressed air.

Advanced Diagnostics

Because compressed air is our business, we can invest in technology that you might not be able to justify for an in-house engineering team.

This includes ultrasonic leak detection to pinpoint costly waste, and an example like Atlas Copco’s AIRScan system, which provides a comprehensive report of your system health, pinpointing inefficiencies and modelling different configurations of your system, providing recommendations that can save you up to 30% of your energy costs.

Longer-Lasting Warranties And Equipment

Proper servicing is usually required to maintain your warranty, and it can often be used to extend your warranty, adding to your protection. Good preventative maintenance will extend the lifespan of your compressor, giving you many years of return on your investment.

But even when things do go wrong, our comprehensive serving options can include round-the-clock callouts and even replacement compressors, ensuring you are quickly back up and running if the worst happens, minimising downtime and production losses.

Choosing the right air compressor servicing provider

Naturally, we think there are countless reasons why you should choose Anglian Compressors, a Branch of Atlas Copco Compressors, to look after your compressed air system.

The Region’s Best Compressed Air Engineers

We invest heavily in our team, ensuring they have the necessary certifications, skills, and knowledge. With hundreds of years of experience between them, our engineers have an unparalleled knowledge and understanding of compressed air.

A Range Of Options

Our compressor service plans are designed to be flexible and cost-effective. We can tailor a maintenance package to your specific service requirements and budget, from simple ad-hoc repairs to all-inclusive service contracts. Our most popular options include:

- Essential Care: This preventative maintenance plan is ideal for standard operations. It includes scheduled service visits by our experienced engineers to conduct all routine checks, replace filters, and manage lubrication, helping to reduce the risk of unexpected breakdowns.

- Performance Plus: This comprehensive service contract includes all the benefits of Essential Care, plus full PSSR 2000 compliance management and priority response for repair services. We act as your 'competent person' to manage your Written Scheme of Examination (WSE), ensuring you remain fully compliant.

- Total Uptime: Our all-inclusive package is designed for mission-critical operations where downtime is not an option. This plan covers all preventative maintenance, 24/7/365 emergency callouts, and all parts and labour for any breakdown, providing complete peace of mind and predictable operating costs.

A Long-Term Partner

Partnership has been a cornerstone of our business since its founding. We view every transaction, even buying a spare part, as a relationship. Keeping your system in the best possible working condition will always be as important to us as it is to you.

We are proud to have worked with some of the region’s biggest companies as they have grown every step of the way.

Start Your Servicing Plan Today

Regular servicing is not an optional extra for your compressor; it is essential. A compressor may be one of your most valuable assets because you rely on the fluid power it supplies to keep your business running.

Delaying maintenance and servicing is a false economy. It increases energy costs, hampering efficiency and risking more serious damage to your system.

Servicing is the best investment you can make for your compressor. In fact, many of our customers can attest that the energy efficiency savings they realise from servicing and audits more than cover the compressor service cost.

Contact us to get the peace of mind that comes with a comprehensive servicing plan. We can arrange an initial consultation to identify your needs and how we can help you.

Many of our customers found that a free chat helped them identify issues that saved them money in the long run, so why not join them and discover why Anglian Compressors, a Branch of Atlas Copco Compressors, is your best option for air compressor servicing?

Frequently Asked Questions

The frequency depends on your specific model, usage (running hours), and the operational environment. A heavily used compressor in a dusty environment will need more frequent checks than one used intermittently. We can create a tailor-made schedule that ensures optimal performance and reliability for your specific needs.